Build List

-

Active Filters:

or

Build Author

Neil Rosenberg

Views

36228

Build Author

Neil Rosenberg

Views

36228

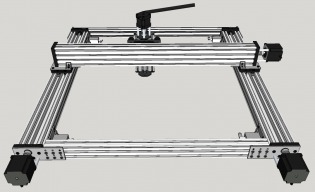

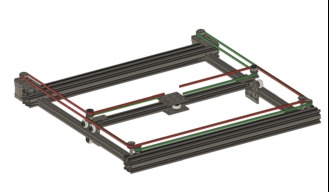

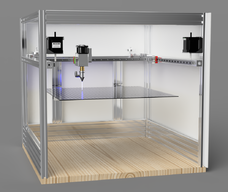

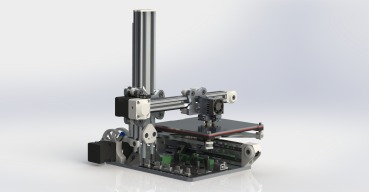

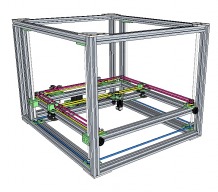

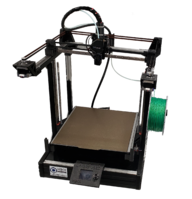

Dash-X 3D Printer: Innovative design

Cross-beam Cartesian 3d printer with dual master/slave lightweight fiberglass drive shafts, BMG style extruder with Bowden (Capricorn) tubing. Hot end is Creality Ender 3 style with two fans and BLTouch for autoleveling. Filament runout sensor is also included.

Build Author

Retsaj

Views

54963

Build Author

Retsaj

Views

54963

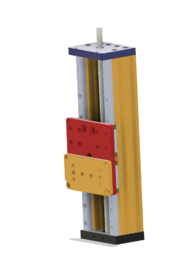

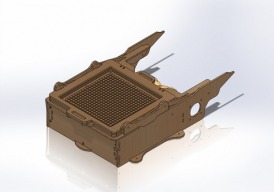

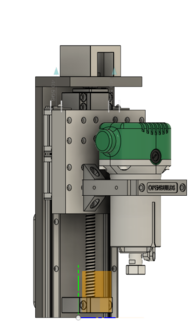

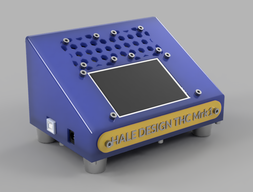

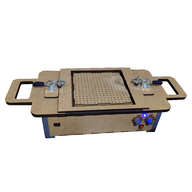

Standalone Torch Height Controller for CNC Plasma Cutting

A Torch Height Controller helps improve plasma cut quality and can save a CNC Machine from crashing. This design doesn't require you to know electronics or need any custom circuits... Its plug and play! This is a COMPLETELY standalone controller with a built-in Driver powerful enough to run just about any stepper motor. (maybe a little to powerful for a NEMA17)

Build Author

Troy Joachim

Views

14375

Build Author

Troy Joachim

Views

14375

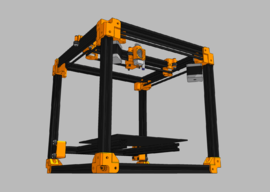

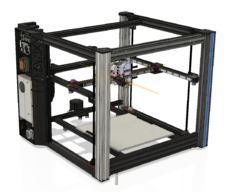

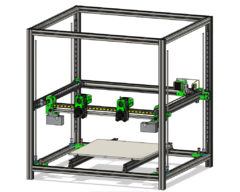

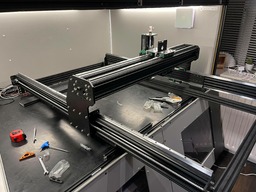

Sigron IDEX

BNC3D Signax + Voron = Sigron IDEX

Build Author

OpenBuilds

Views

20158

Build Author

OpenBuilds

Views

20158

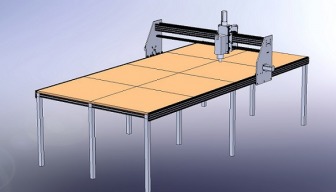

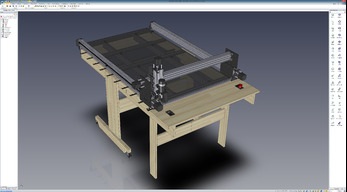

OpenBuilds Table Series

The OpenBuilds Table Series offers a modular table structure that grows with your needs.

Build Author

Scott Drake

Views

15977

Build Author

Scott Drake

Views

15977

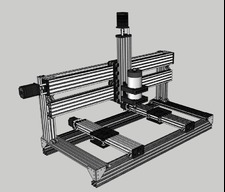

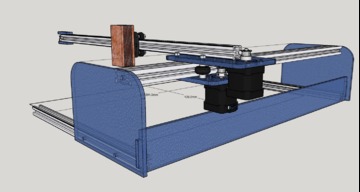

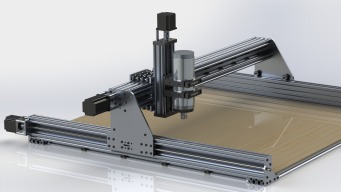

1500x1000 CNC Router

1500x1000, additional frame stiffening from laser cut Stainless steel bracing plates, Nema 34 motor upgrade and Hiwin 16mm ballscrew additions on the way. Ethernet Smooth stepper control, 2.2kw Water cooled spindle. Schneider atv320 variable speed drive. SICK inductive limit switches, Leadshine Em882S stepper drivers ,1kw 62V supply for Stepper drives

Build Author

Joe Young

Views

11732

Build Author

Joe Young

Views

11732

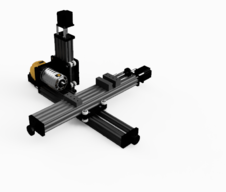

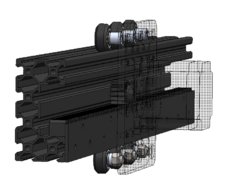

Rack and Pinion (Death to Belts)

Low profile rack and pinion linear actuator design

Build Author

Mark Carew

Views

19983

Build Author

Mark Carew

Views

19983

V-Slot™ Nema 23 Linear Actuator (Belt Driven)

This example build shows how easy it is to make a linear actuator using a few OpenBuilds Parts.

Build Author

Bob Darrow

Views

6833

Build Author

Bob Darrow

Views

6833

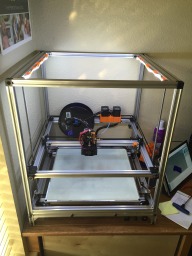

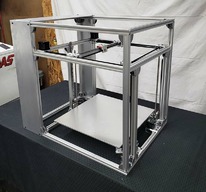

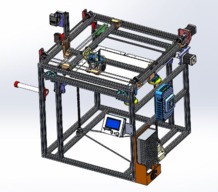

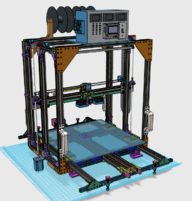

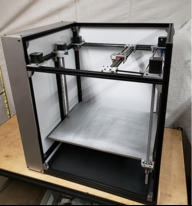

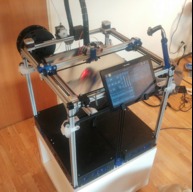

BA3DP

A slightly more than one half cubic meter 3D Printer using V Rails, V Rollers, "C" Rail, mounting plates, and a bunch of 3D printed brackets to provide strength and stability to the frame. Rigidity was the goal and precision and accuracy the result. The software is a whole other topic, many weeks spent dialing that in to make the printer print.

Build Author

Mark Carew

Views

58417

Build Author

Mark Carew

Views

58417

V-Slot NEMA 23 Linear Actuator (Lead Screw)

Learn to build a super strong nema 23 lead driven linear actuator

Build Author

cdsmith12

Views

25508

Build Author

cdsmith12

Views

25508

The Plastic Beast CoreXY Printer

In my opinion, this is the easiest and most complete tutorial to walk you through building a large platform 3D printer and the Sketchup File is included for you to make any changes needed.. The Plastic Beast is a CoreXY Printer with a build platform of 440mm square. You can print 600mm or about 23 inches diagonal. Any level of user from novice to expert should gain something from my tutorial.

Build Author

Mark Carew

Views

118512

Build Author

Mark Carew

Views

118512

C-Beam™ Linear Actuator

Here are a few helpful C-Beam actuator ideas that will help you get a start on your builds

Build Author

Frank Del Favero

Views

5785

Build Author

Frank Del Favero

Views

5785

Portable self-contained Lead 1010 table

I have a two car garage NOT devoted to 3d printing or CNC. I have set aside a space for my 3d printer and a place to store my portable CNC table. The reason it’s portable is so that I wheel and can use my Lead 1010 outside where it won’t make a mess in the garage. The table is self contained. It houses a vac system as well as my CNC tools and supplies.

Build Author

Ryan Lock

Views

125948

Build Author

Ryan Lock

Views

125948

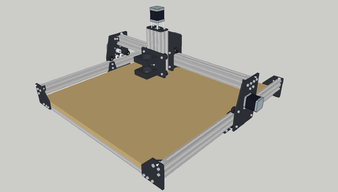

WorkBee CNC Machine

The WorkBee is our latest CNC Machine and is a culmination of all our experience, feedback, and suggestions from selling the OX CNC Machine over the past 2 years. The WorkBee is capable of accurately cutting foams, woods, plastics or aluminum at depths greater than 25mm to 0.2mm accuracy or greater.

Build Author

Suhmanda

Views

2505

Build Author

Suhmanda

Views

2505

DIY CNC SPINDLE

CNC SPINDLE FOR DIY ROUTERS AND MILLING MACHINES ITSRS-985 MOTOR HAS MUCH BEFINITS THAN ANY OTHER DC MOTOR IN MARKET

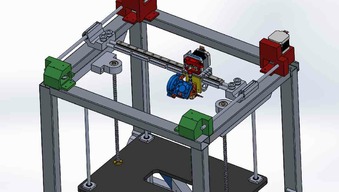

Gauthali V2.0 DIY 3D printer

This is based on core XY kinematics. First of all, we designed a CAD model. Most of the required parts are designed by us in solidworks software, and some parts are downloaded from a web platform ‘grabcad’. After that we assembled those parts and inspected them in solidworks. The designed CAD models are frame of 470mmX392mmX545mm SBR linear guide rod, linear guide holder, lead screw, motor mounts, pulley, bed mount, idler block, timing belt clamper.

Build Author

alan richard

Views

46142

Build Author

alan richard

Views

46142

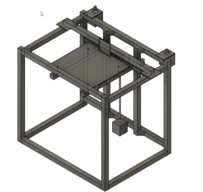

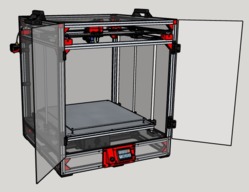

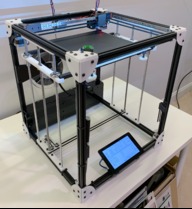

Core-XY Cube

An enclosed cube shaped 3D printer using CoreXY motion. Fabricated from V slot extrusion, standard extrusion, aluminium plate and acrylic sheet using basic workshop tools. Using standard RAMPS/ Reprap electronics. Technically a 'Repstrap' currently used to build a true 'Reprap'

Build Author

Mark Carew

Views

14027

Build Author

Mark Carew

Views

14027

C-Beam XLarge X/Y Table

This OpenBuilds C-Beam XLarge X/Y Table is a great display of how easy it is to modify and create awesome configurations with the OpenBuilds system!

Build Author

OpenBuilds

Views

13245

Build Author

OpenBuilds

Views

13245

C-Beam® Tension XL Linear Actuator

Bringing your lead screw precision and accuracy to new lengths using a simplistic tension system!

Build Author

Mark Carew

Views

69803

Build Author

Mark Carew

Views

69803

OpenBuilds Workbee 1010 (40" x 40")

The OpenBuilds WorkBee 1010 - 1000x1000 Lead Screw Driven CNC Machine

Build Author

Jason Moore

Views

10727

Build Author

Jason Moore

Views

10727

Lead1500 Plasma Table w/THC

lead machine plasma table with Black Box, and Torch Height Control

Denford CNC Resurrection

Denford CNC Mill Update

Build Author

alex_b

Views

16776

Build Author

alex_b

Views

16776

TACIT RONIN CNC - Flood Coolant Enabled C-Beam

The TACIT RONIN CNC is a fully enclosed C-Beam platform intended for flood coolant cutting of Carbon Fiber and G10 composites.

Build Author

Cam Garrett

Views

2549

Build Author

Cam Garrett

Views

2549

Sturdy Motorized Photographic Copy Stand

i would like to build a sturdy motorized photographic copy stand. i have hobbled together a hand crank version using a used umbrella pole but it is not suitable as it is awkward and wobbly.

Build Author

OpenBuilds

Views

3488

Build Author

OpenBuilds

Views

3488

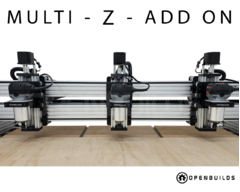

Multi Z LEAD Machine Addon

The Multi Z adds multiple Z axis to a LEAD CNC Machine allowing it to cut and carve 2 to 3 times the amount of projects in the tame it takes to make just one

Dedicated Rotary Laser Made from Scrap and Spares

A clone of https://openbuilds.com/builds/dedicated-compact-rotary-axis-laser-engraver.10204/

CoreXY W/ Fixed Build Plate & Enclosure

Building a Core XY printer with a fixed build plate from off the shelf parts.

Build Author

Sonny Lowe

Views

5418

Build Author

Sonny Lowe

Views

5418

MakerSL MSL-65 Manual Coffee Grinder Stand

I know this build is a little off category here at OB, but I wanted to share it with the community (as well as other coffee lovers) and show however vast the possibilities are when OB hardware is involved. This is a powered stand intended to operate a manual coffee grinder. It is compact, light, portable and uses simple drive components (B&D Cordless Screwdriver). I will post two version, V-1 (Beginner skill level ) and V-2 (Intermediate skill level). Both accomplish the same results.

THE BIG GREEN MACHINE

1500*1500*1900 (xyz) Biocomposite Pellet 3D printer

Build Author

nc3dpw

Views

21020

Build Author

nc3dpw

Views

21020

(Portable) Large Format 3d Printer 4ft square frame. Build Volume 36in x 36in x 36in

Large format printer build based off successful small Corexy. I figured it could be scaled to large format and be portable. Portable meaning by removing a few pieces it could effectively be rotated out of a standard door frame.

Build Author

JCPhlux

Views

24477

Build Author

JCPhlux

Views

24477

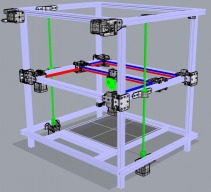

Tesseract

Large Core XY 3d Printer W/fixed build plate

Build Author

BNMaker

Views

10112

Build Author

BNMaker

Views

10112

+Laser

A minimalist 2-axis A2 sized laser diode cutter/engraver. Designed to give the most function using the very least number of parts at the lowest price.

Dragon Portable CNC Plasma Cutter

A small portable CNC Plasma Cutter with some unique features

Build Author

Indieflow

Views

110648

Build Author

Indieflow

Views

110648

Indie i2

A lightweight, portable, accurate 3D Printer that has a good sized print area and small overall footprint that is easy to build, with easy to source components. The design is OpenSource allowing those with the capability to make their own parts get up and running.

Build Author

Leonard Cross

Views

34183

Build Author

Leonard Cross

Views

34183

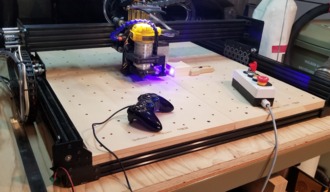

Workbee CNC Router/Laser/Plotter

A CNC machine with an expansive 30x30" work area, supporing a router, laser, simple plotting and work monitoring camera. Control includes a tethered control box, game controller style jog control, and relay controlled AC outlets for all appliances. Accessories include a 3D printed dust shoe, a complete spoilboard and hold down system, an XYZ touch probe and multiple vacuum retention boards to support full profile routing.

New Workbee Z Axis

Hopefully an upgrade of the Z axis of the Workbee.

Travel Printer

Build using standard parts as much as possible, Open Builds etc. To keep printer usable for more materials will be trying a heated bed with rotary elec union for the thermistor and power.

SolidCore CoreXY

All metal CoreXY 3D Printer Design with triple z, kinematic bed, and scalable corexy mechanism.

Shawn's Workbee 1510

Shawn's adventure in assembling and customizing the Openbuild's version of the 1500x1000 Workbee.

Build Author

Serge E.

Views

59178

Build Author

Serge E.

Views

59178

myOX : a 4' x 2' OX CNC with potential

This is the story of me building myOX - my version of the "ideal" OX. I want a machine which can route/mill at least 4' wide and as long as I can feed through (don't be shy, think "infinity") as well as going deep on multiple faces - manual 4th axis. I have loads of ideas to take myOX towards that goal and way beyond. Time will tell. Just follow along through this build and possibly a few others along the way ... Check out my OXCalculator : let your computer figure out your BoM

Build Author

Frank Gore

Views

7455

Build Author

Frank Gore

Views

7455

Kossel Extreme

A custom Delta printer for large projects with any filament that still retains speed and accuracy, all within a 15 amp/110VAC power budget. Based on Johann's Mini Kossel design.

Build Author

BeTrue3D

Views

20349

Build Author

BeTrue3D

Views

20349

BeTrue3D Printer

High Quality CoreXY with focus on quality and optimized printarea versus physical size of the printer.

Build Author

Edgar Mata

Views

21040

Build Author

Edgar Mata

Views

21040

ME - Core XY 3d printer

I wanted to make my own Voron, so I made my own Voron,

Build Author

T4Concepts

Views

72710

Build Author

T4Concepts

Views

72710

WorkBee CNC build - My honest opinion, tips and help

My main goal for my build is to have a machine that is capable of profiling and help me in my designs, for the manufacture of custom automotive headlights.

Draw bot core xy

In the design stage. Help guide.

Robo Morten

A horizontal-router CNC using openbuilds parts geared toward routing out mortise and tenon joinery; or any other end grain work on wood.

Build Author

Martin.Barfoed

Views

5247

Build Author

Martin.Barfoed

Views

5247

40x40 V-Slot Rod Type Linear Actuator

A Rod-type Linear Actuator based on the 40x40 V-slot profile

Build Author

shanehooper

Views

12750

Build Author

shanehooper

Views

12750

SolidCore CoreXY 3D Printer

Modular and Scalable CoreXY Printer with all metal parts.

Adjustable Router Guide Template

This project is an adjustable router guide template made with 20x60 V-slot. It was meant as a less expensive and more user friendly alternative to commercially available units.

Stabilus 3d Large Format Printer Kit

Stabilus 3d Large Format Printer Kit

Build Author

crypt-tek

Views

32468

Build Author

crypt-tek

Views

32468

C3DO

My first 3D printer build. It is almost complete and will be posting the first completed print shortly. I still need to mount the print spools and a couple other odd ends to complete this.

Phlatformer v2

Hello, I have been looking around for a vacuum forming machine for a long time, and could not find one that was either in my price range or was safe enough for me to want in my home. The Phlatformer answers both of these requirements... Unfortunately, it was not available in either cut-out or...

Build Author

Mike Campbell

Views

9361

Build Author

Mike Campbell

Views

9361

bor 454-D

A large format, modular, rack and pinion build designed around OpenBuilds components.

Build Author

rengelking

Views

30250

Build Author

rengelking

Views

30250

Vacuum Forming Machine

Vacuum Former built with off-the-shelf parts, works perfectly every time!

Build Author

Keith Davis

Views

29154

Build Author

Keith Davis

Views

29154

OpenXY

Combines the layout factor of a CoreXY while using Cartesian logic. The design has a fixed build plate - moving an X/Y frame on the Z axis enclosed by an outer main frame.

Build Author

SOA

Views

58613

Build Author

SOA

Views

58613

GridBot Two: Powerfully Simple

Core XY, sensor-less homing, integrated camera, touch screen, pi, 32-bit controller, fast, quiet, beautiful prints. 300 x 300 x any build volume. Just change out the Z lead screws, rods, and four pillars. Total BOM around $700 USD. Build time around 6 hours.

Based on 608 tube Plasma Cutter

Simple steel tube design Plasma water table

PnP 4 axis small/fast machine

You need some mechanical and electronic experience. This is NOT a novice undertaking! a familiarity with linux a plus (but not necessary). Basic woodworking and metal fabrication a big plus as well.

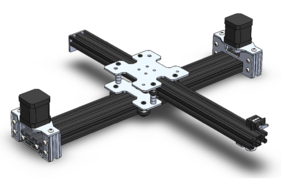

All Metal - CoreXY Motion

Stacked CoreXY Motion System using only Openbuilds components

Build Author

Mark Carew

Views

77530

Build Author

Mark Carew

Views

77530

OpenBuilds Workbee 1510 (60" x 40")

The OpenBuilds WorkBee 1510 - 1500x1000 Belt Driven CNC Machine

Build Author

lekey

Views

7090

Build Author

lekey

Views

7090

Modular Desktop Vacuum Former

This is a small desktop vacuum former that can be connected to a shop-vac and an electric heat source (like a grill for instance). You can control the time each appliance stays turned on, and the vacuum is automatically turned on when the tray is placed on top of the model. The vacuum table is 20x20cm wide, and I've tested it mostly with 1mm thick PET sheets.

Build Author

txcomp

Views

5829

Build Author

txcomp

Views

5829

WorkBee 1010 "Get Rid of the Slop" Build

My goals for this build were to eliminate slop and flex while also allowing easy serviceability.

Build Author

shanehooper

Views

25750

Build Author

shanehooper

Views

25750

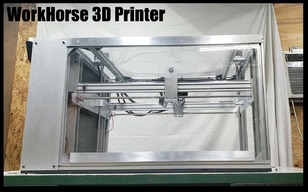

Workhorse 3D Printer

Large 600mm x 350mm x 350mm Build Volume with lead screw driven motion. The printer build has a moving gantry and fixed heat bed. Open Source

A very affordable CNC routing

In progress CNC, (just design for the momment), I want to get some feedback about the design and the possible flexion of the aluminum profiles chosen

Corexy laser

I have tested my Opt Lasers laser module on a "open" frame for some time. Decided that I want to test a corexy setup and combine it with a boxed/enclosed design - my goal is to get high precision + a safe setup with protection from the laser light + a fan to extract the smoke/exhaust..

Custom push cart for CNC machines

I’m custom building a push table / cart for my cnc machines mostly out things I already had in my garage. Using a gray push utility cart as the main body and building around that.

Build Author

ckgottabuild

Views

2814

Build Author

ckgottabuild

Views

2814

Lead CNC 1010 Platform and Rotating Laptop Mount

Moveable Lead CNC1010 build with handles on four corners. Everything fits on one sheet of cut out 4x8 plywood

Some Improvements on the Workbee 1000x1000

Improvements both real and suggested for the Workbee assembly

Workbee with less irritations

My workbee build with some add ons

3000x1500 CNC

Here is my Project A CNC 3000 mm by 1500 mm, with a 2.2kW spindle collet ER25 and 4 stepper motor nema 23 425oz-in. The purpose being to have a large work surface for a minimum cost.

Build Author

CNCGear

Views

8742

Build Author

CNCGear

Views

8742

The BlackBee CNC

Ball screw drive, linear rail CNC Kit

Rotary axis for Workbee

Adding a rotary axis to the Workbee 1010. Including height modifications to the Workbee.

Build Author

Mark Carew

Views

19940

Build Author

Mark Carew

Views

19940

C-Beam® XLarge Linear Actuator

This OpenBuilds C-Beam XL actuator is the backbone of a lot of the awesome builds put together by the OpenBuilds community

Build Author

crypt-tek

Views

8983

Build Author

crypt-tek

Views

8983

crypt-cube

The crypt-cube is another project I've been working on off and on over the past year, unlike my previous built C3DO this is a much smaller built with a volume of 318mm x 240mm x 220mm. With this build my main focus is precision and speed.

Workbee with Duet controller

Workbee 1010 with Duet controller from Ooznest

Build Author

Mark Carew

Views

12841

Build Author

Mark Carew

Views

12841

NEMA 17 Belt and Pinion Actuator

This Belt and Pinion actuator is a great example of how easy it is to convert your machine into a belt drive system.

TITANXY (Fixed Build Plate, Quad Z Screw, CoreXY)

Super Rigid CoreXY 3D Printer

MOVABLE ART TO SCREEN WALL-MOUNTED TV

This project produced a movable framed canvas to cover a wall-mounted flat-screen TV when not being viewed, which at the touch of of a switch moves down below the TV and sound bar. The same switch is used afterwards to return the artwork up to cover the TV again. Photo shows mechanism without the canvas frame. See other photos.

Keeping thing quiet with a custom C Beam XL

A small form factor machine in a soundproof enclosure

The BEE and ME

I have always wanted to work with CNC machinery...a few years back I got my chance to learn some basics at the Double Glazing Company where I was employed (very basic I might add) before the firm folded and I was made redundant...I wanted to continue learning and when I came across this site which push affordable machines I thought I'd give it a go. So I purchased a !000mmx750mm Screw Driven Workbee from Ooznest and I'm about to embark on my quest as many have done before me...Wish me Luck!

Build Author

John Pollman

Views

6148

Build Author

John Pollman

Views

6148

Wanhao Duplicator i3 Plus - Major rebuild.

Major rebuild of my Wanhao Duplicator i3 Plus.

Retractable WorkBee1510 with Marlin+MarlinPanel high level build

WorkBee1510 with retractable space saving stand and customize build Marlin firmware and MarlinPanel (GCode Sender/UI)

Build Author

Jacob Lotter

Views

22359

Build Author

Jacob Lotter

Views

22359

1510 Workbee Modified

Some of the things that I have done to my 1510 Workbee Installed Linear rails and bearing blocks with drawings. Installed Ops console Made conversion plates for extruded aluminum to casters Extended z axis travel by a couple inches with steel plates. As of now in the process of installing Lead screws across the 1500mm length.

V-rex , Low cost CoreXY

Easy to build,low-cost, CoreXY

CoreXY Cubish

A dual extrusion CoreXY printer with a 290 X 290mm build volume built entirely out of 2020 aluminum extrusion and using openbuilds mini-carriages for motion.

Voxel Evolution

This is a remix of Marshal Peck's Voxel OX, with some design tweaks inspired by Makerparts and jjcolletta. It has a build area of 300mm X 300mm X 480mm, but is easily configured for just about any build area up to 500mm X 500mm X 750mm. I have used some laser cut acrylic plates and a couple of 3D printed parts in its construction, however it can be assembled using nothing but OpenBuilds parts with the exception of the heated bed and the Y axis carrier for the heated bed.

YAWBM - Yet another Workbee Modification

Increase Z axis travel by 20-25mm with minimal modifications

Build Author

Mark Carew

Views

14716

Build Author

Mark Carew

Views

14716

Nema 23 Belt and Pinion Actuator

This easy to build and effective system can take your builds to the next level! This design is strong and accurate and could be the solution/upgrade that you've been looking for!

Horizontal CNC V-Beem v1

V-Beem horizontal milling machine built on OpenBuilds components. Simple structure, great expansion possibilities, high stiffness.

Build Author

Robert Mech

Views

7897

Build Author

Robert Mech

Views

7897

LayerFused X301 - CoreXY Large Volume Printer

The X301 is a CoreXY 3D Printer that has a small footprint and a large 300x300x330 build area. The open style of this printer breaks the "Cube" mold of many other printers in this class but still retails rigidity and great performance.

Build Author

Mark Carew

Views

102727

Build Author

Mark Carew

Views

102727

V-Slot® NEMA 17 Linear Actuator Bundle (Lead Screw)

Example model of lead screw driven actuators for your next project!

Build Author

Crazzy French Dude

Views

3896

Build Author

Crazzy French Dude

Views

3896

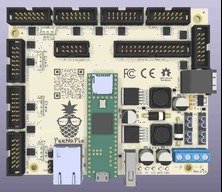

PeeNaPle_V1.4b

PeeNaPle_V1.4b is a BoB controller board for 3D Printers, CnC and cartesian machine, using the latest Teensy_4.1

My giant "WORKBEE" 1750mm X 1750mm by ooznest

CNC MACHINE WORKBEE'S table making

Build Author

Apothus

Views

21072

Build Author

Apothus

Views

21072

Sphinx rigid XL

Rigid variant of the C-Beam sphinx platform

Build Author

Roy Berntsen

Views

23825

Build Author

Roy Berntsen

Views

23825

V-King CoreXY

V-King CoreXY 3d Printer- 380*340*340 Build volume - All wheels on V-Slots - Belts on XYZ - High quality and controlled design - Proven fast, reliable and it is all open source

Build Author

Rat Rig

Views

28804

Build Author

Rat Rig

Views

28804

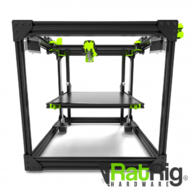

Rat Rig V-Core 3D Printer ( Core XY )

Fully OpenBuilds based Core XY printer design by Rat Rig. CAD files, build manual, build videos available!

SCoreXY

Currently I have Velleman/3Drag K8200 modified and CNC machine self built and wanted to use both to make new 3D printer. After looking at different designs I liked Voron a lot and have decided to go that way. Currently I have ordered majority of parts and build shall start soon. I don't plan to rush it as I am usually 2 months home and 2 off. Today done some electronics. Looks ok. https://youtu.be/ls_tl54ruE0

My Ooznest Workbee V2.0 build

I'm new to this whole process, so this is a build by a newbie for newbies.

Workbee Z-axis Upgrade

Z-Axis upgrade with linear rails, SFU1204 Ball Screw and full aluminium construction.

ApiNui - CNC Router ( an oversized workbee )

Based on the WorkBee CNC, this is an oversized router built with a specific use-case in mind, for manufacutring beehives, and beehive components