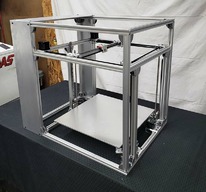

SolidCore CoreXY 3D Printer

![[IMG]](proxy.php?image=https%3A%2F%2Fi0.wp.com%2F3ddistributed.com%2Fwp-content%2Fuploads%2F2021%2F10%2FSolidCore_CoreXY_Motion_System_Platform_3D_Printer_Kit.jpg%3Fresize%3D768%252C768%26ssl%3D1&hash=31f4354e779e1d66820a987ccb65c7b4)

While the SolidCore printer design is still a work in progress, the corexy build is slowly materializing. The SolidCore uses aluminum parts which makes the printer a highspeed workhorse for repeated use. For now, we decided to go with a simple core-xy design but have future plans for a toolchanger and a heated chamber. The design goal is to build a reliable high speed 3d printer or for 3d printing high temperature materials.

- All Metal

- Simple but Compact Design

- Linear Rails

- Enclosure

- Triple Z-Axis

- Kinematic Bed Mounting System

All-metal-parts and components will give us the durability and repeatability needed. The SolidCore CoreXY design has the motor and idler parts assemble to the inside corners of the frame. This mechanical arrangement is better for adding an enclosure and scaling up the 3d printer size to a larger build area. Minimizing design constraints of overall 3d printer length and width makes the machine completely scalable and customizable.

But we want people to have the option to use 3d printed parts so they can upgrade later on. Solid all metal parts are durable and less likely to deflect at high printing speeds. The aluminum components are also less likely to breakdown over time when introduced to the forces and heat from repeated use.

Carriage Design

The carriage and gantry are designed to be light weight and strong. We currently use c-shaped aluminum stock because it reduces machining time. The reduced machining time and minimized waste helps but it’s a compromise. That’s going to change soon. We’ll probably make some changes such as reorienting the the y-axis linear rail into a vertical position similar to the RailCore but the current horizontal version will be easier to adapt an E3D Toolchanger.

SolidCore CoreXY

Build in 'H-Bot and Core XY' published by shanehooper, Jun 6, 2022.

All metal CoreXY 3D Printer Design with triple z, kinematic bed, and scalable corexy mechanism.

-

-

-

- Build Progress:

-

- Build in Progress...

Jeffj and Mark Carew like this. -

-

Build Author shanehooper, Find all builds by shanehooper

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution Share Alike - CC BY SA

-

Attached Files:

-

![[IMG]](proxy.php?image=https%3A%2F%2Fi0.wp.com%2F3ddistributed.com%2Fwp-content%2Fuploads%2F2021%2F05%2Fsolidcore-corexy-v1-mechanism-hotend.jpg%3Fw%3D768%26is-pending-load%3D1%23038%3Bssl%3D1&hash=14ab91fcc64dd101cdf4e6556cfb8fc9)

![[IMG]](proxy.php?image=https%3A%2F%2Fi0.wp.com%2F3ddistributed.com%2Fwp-content%2Fuploads%2F2021%2F05%2Ftriangle-idler.jpg%3Fw%3D768%26is-pending-load%3D1%23038%3Bssl%3D1&hash=5bfc7dd4d5e39964f4d05d784d52ffa1)

![[IMG]](proxy.php?image=https%3A%2F%2Fi0.wp.com%2F3ddistributed.com%2Fwp-content%2Fuploads%2F2020%2F11%2FSolidCore-CoreXY-Carriage-Y-Carriage.jpg%3Fresize%3D768%252C526%26is-pending-load%3D1%23038%3Bssl%3D1&hash=fc4ae5eccb10921d4dccf567fc494e77)

![[IMG]](proxy.php?image=https%3A%2F%2Fi0.wp.com%2F3ddistributed.com%2Fwp-content%2Fuploads%2F2021%2F04%2FIdler-Mounts.jpg%3Fw%3D768%26is-pending-load%3D1%23038%3Bssl%3D1&hash=818126f969fd87a8489eef43831b3c78)

![[IMG]](proxy.php?image=https%3A%2F%2Fcdn.thingiverse.com%2Fassets%2Fe6%2Fae%2Fa9%2Fb5%2F2f%2FKinematic_bed_assembly_solidcore_corexy.jpg&hash=f6c6e4bd75704462319633631aebf52c)