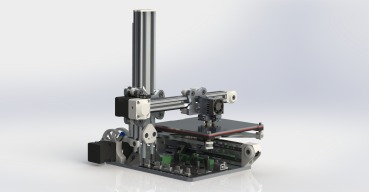

Introducing the Indie i2

INTRODUCTION

After building numerous 3D Printers including the original Prusa, Prusa i3 single plate and the Huxley I decided to combine the features I liked from each into my own design. Additionally after seeing the Bukito by Deezmaker, Omerod by RepRapPro and the Printrbot Simple by Brook Drumm I decided to base the frame on a crane style.

List of design features:

Lightweight and Portable – To be transportable I wanted to keep the weight as low as possible though still keep the functionality of the printer. For this reason I decided to base the design around the smaller Nema 14 stepper motors that provide more than enough torque in a much smaller package. I also designed the printer so that it can be flat packed by splitting it down to the 3x main axes to be safely stored in a case for transport.

Versatile – To be able to increase the adaptability of the printer for use with different types of material (PLA/ABS etc) and allow further development of the use of these materials I incorporated a heated bed. This would also hopefully alleviate any potential bed adhesion problems.

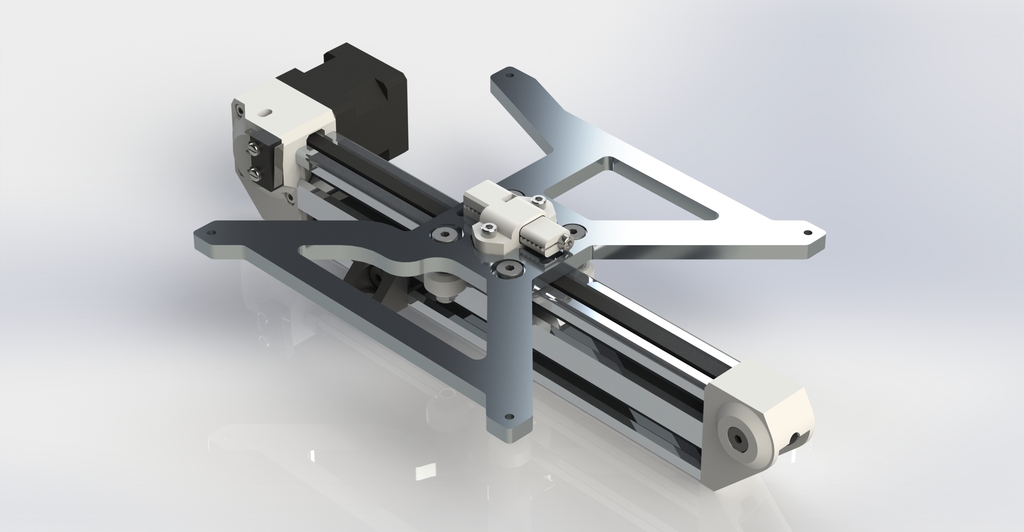

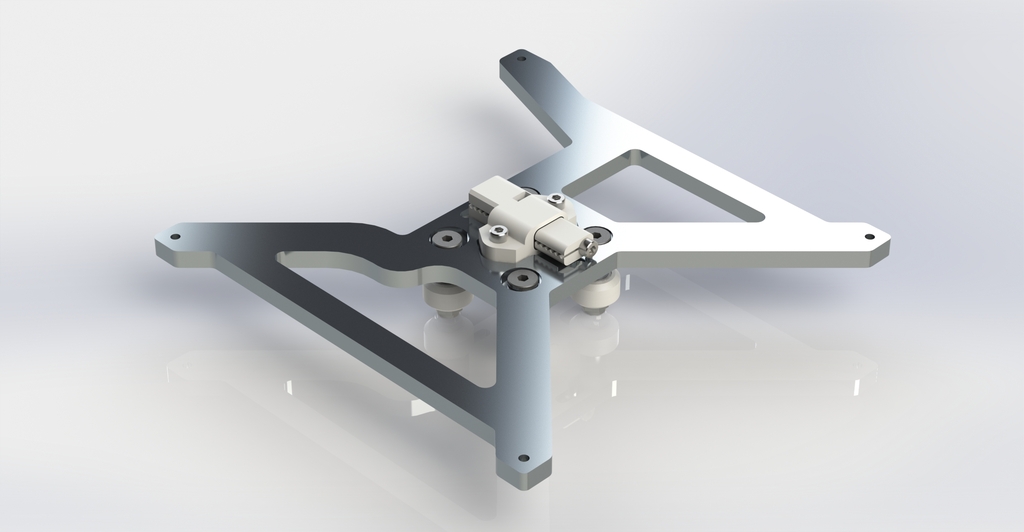

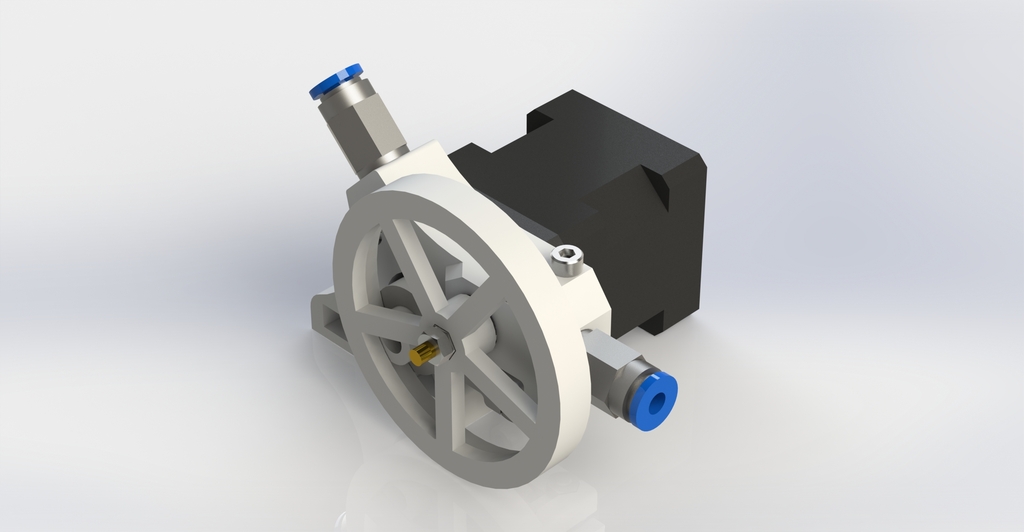

Stable – With each printer I have previously built the weakness has been the stability of the Z axis as a result of the motion of the X axis. With the crane style design only having one Z axis support I wanted to minimize the weight being transferred across this axis and so I incorporated the use of a Bowden system.

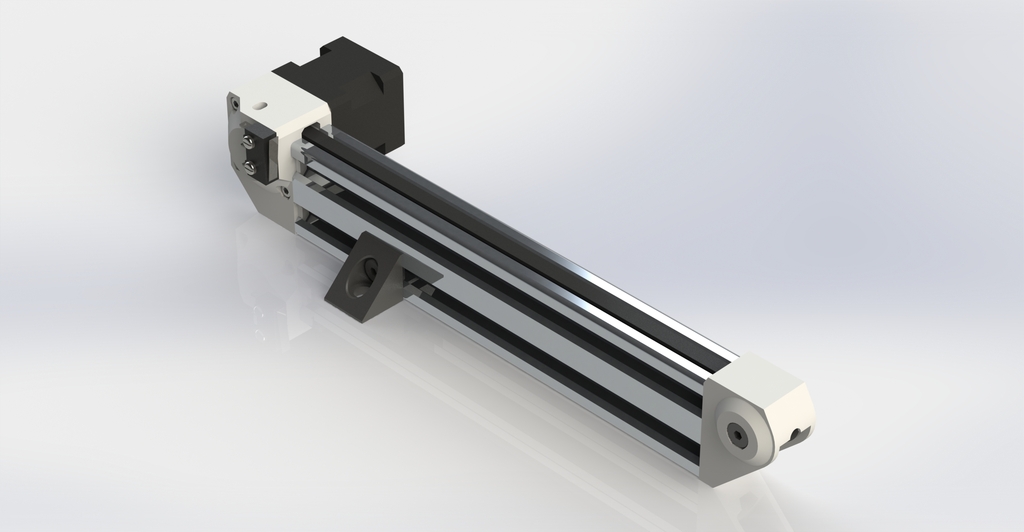

Noise – After using Linear Bearings for motion on all my other printers I decided to try using wheels and bearings to reduce the noise and found Openbuilds V-slot system to be a suitable choice.

Print Area – The printable area of the printer is 140x140x140mm which is large compared to the overall size of the printer – making the most of the space available.

AVAILABILITY

The majority of the components used for this build are available directly from OpenBuilds and those that aren't have links in the Parts List tab. Additionally if you don't want to pay the extra cost for buying excess quantities or multiple shipping charges then message me for the following kits:

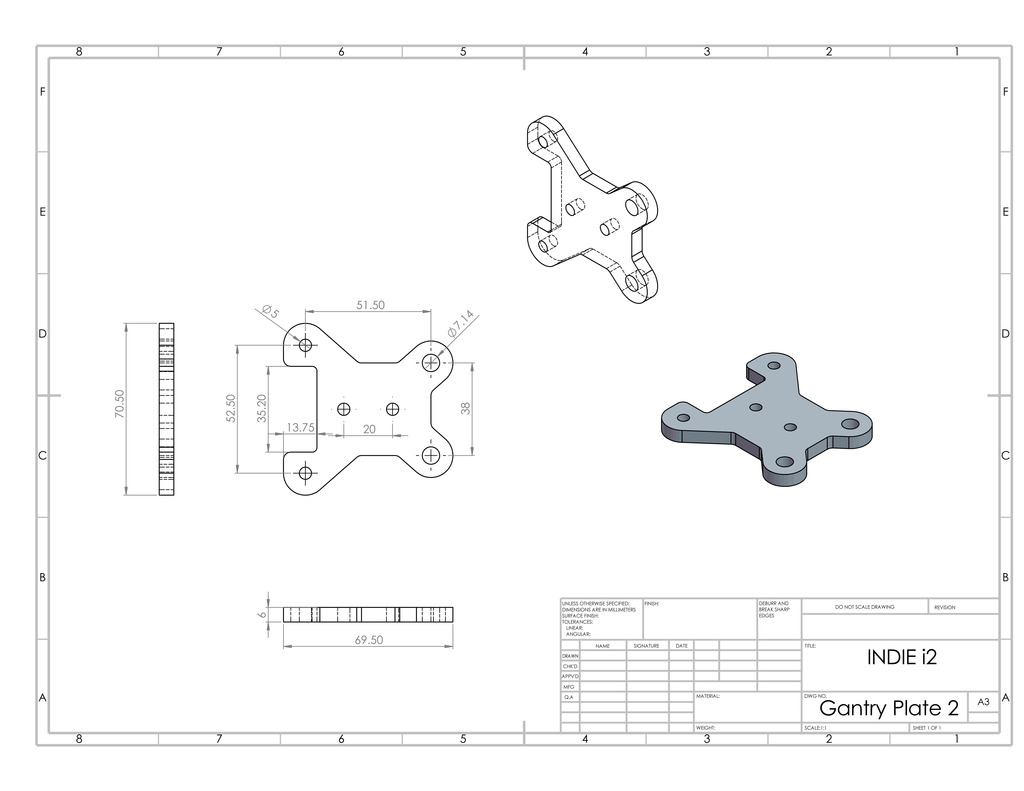

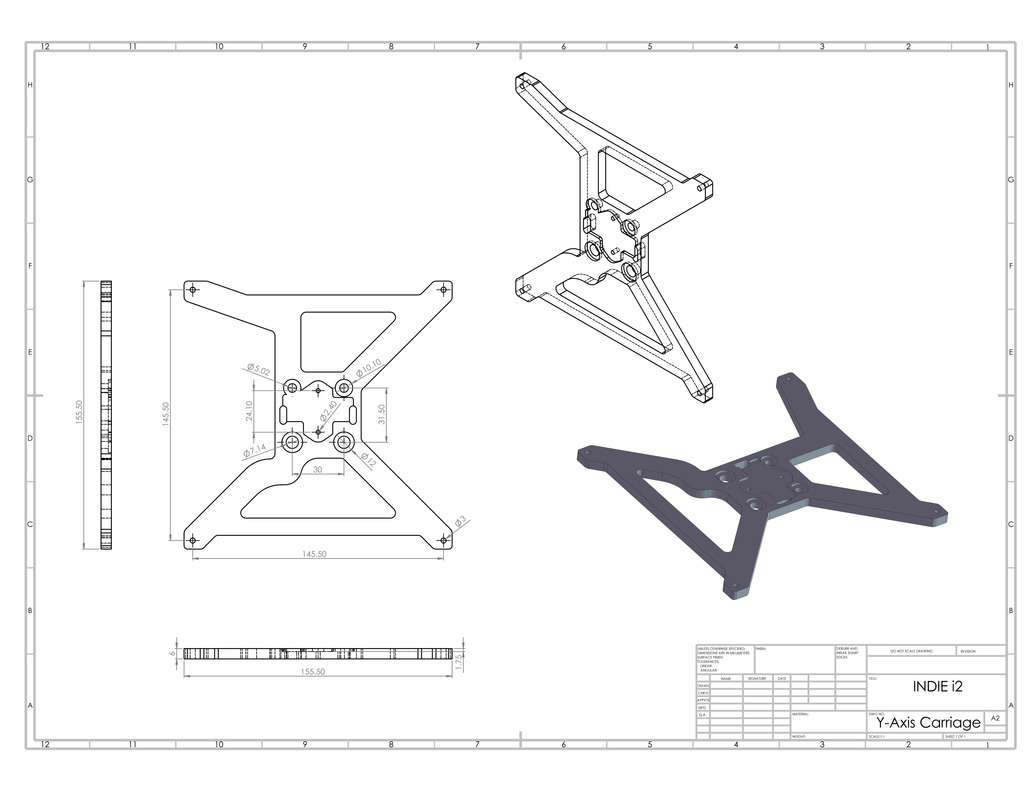

- Aluminium plates for those that don't own a CNC machine - eBay.

- Heated bed and shields - eBay.

- 3D Printed parts are available for those that don't already own a printer.

BUILD INSTRUCTIONS

X-AXIS

Y-AXIS

Z-AXIS

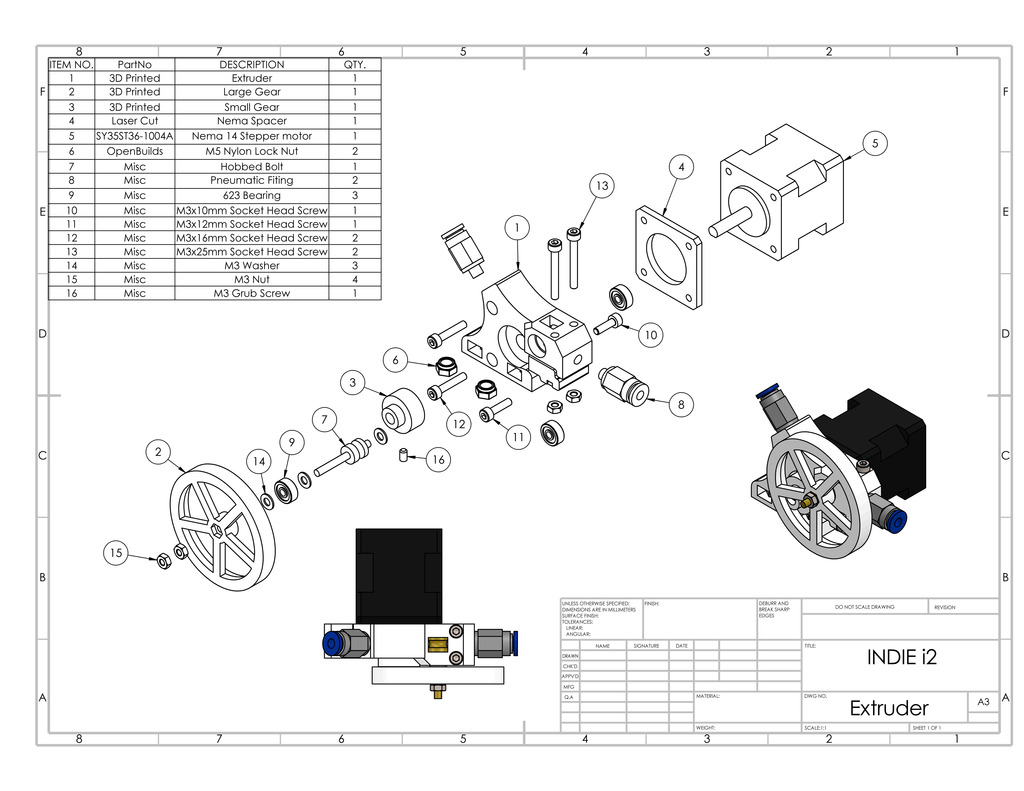

EXTRUDER

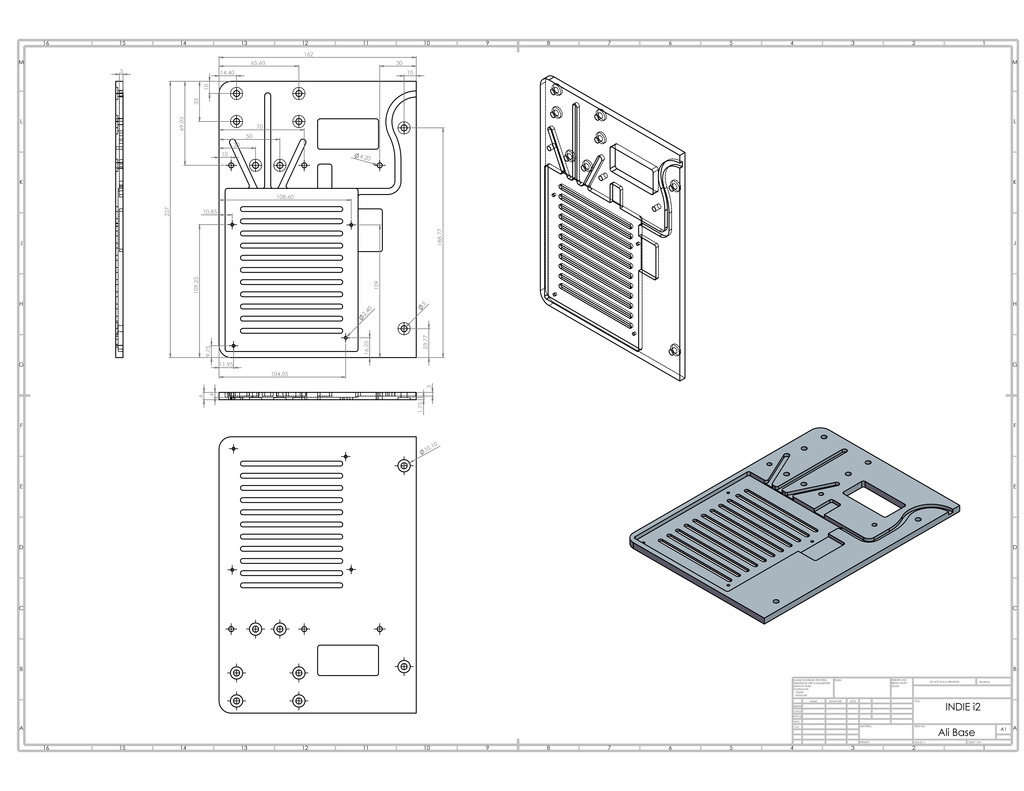

BASE PLATE

FLAT PACKED FOR TRANSPORT

As one of my aims was to make the 3d Printer transportable I ensured the design could be easily broken down into the 3 main components (X, Y & Z Axis). This then allows the printer to be, as such, flat packed in a protected case (Storm Case im2200) for easy transport. The printer can be broken down, or rebuilt in around 15 minutes time and following a quick calibration can be up and running.

![[IMG]](proxy.php?image=http%3A%2F%2F%3Ciframe+src%3D%22%2F%2Fgiphy.com%2Fembed%2Fy5xRFqfdkgEXS%22+width%3D%22480%22+height%3D%22480%22+frameBorder%3D%220%22+class%3D%22giphy-embed%22+allowFullScreen%3E%3C%2Fiframe%3E%3Cp%3E%3Ca+href%3D%22http%3A%2F%2Fgiphy.com%2Fgifs%2Feaster-edition-gizmodo-y5xRFqfdkgEXS%22%3Evia+GIPHY%3C%2Fa%3E%3C%2Fp%3E&hash=652839bb026fbe9a9f452e9608684bd3)

Indie i2

Build in 'Cartesian Style Bots' published by Indieflow, Mar 10, 2021.

A lightweight, portable, accurate 3D Printer that has a good sized print area and small overall footprint that is easy to build, with easy to source components. The design is OpenSource allowing those with the capability to make their own parts get up and running.

-

-

-

- Build Progress:

-

- Build Complete!

-

-

Build Author Indieflow, Find all builds by Indieflow

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution NonCommercial - Share Alike - CC BY NC SA

Reason for this Build

After owning/building numerous 3D Printers I decided to combine those features I liked from each into my own design.Inspired by

RepRapPro (Huxley & Ormerod), Deezmaker(Bukito), OpenBuilds (V-Slot system). -

Parts list

-

Attached Files:

-

![[IMG]](proxy.php?image=http%3A%2F%2F%3Ca+data-flickr-embed%3D%22true%22++href%3D%22https%3A%2F%2Fwww.flickr.com%2Fphotos%2F152530055%40N06%2F35687027881%2Fin%2Fdateposted-public%2F%22+title%3D%22Extruder%2520Assembly_zpsofjgcl45%22%3E%3Cimg+src%3D%22https%3A%2F%2Ffarm5.staticflickr.com%2F4236%2F35687027881_4ecd95bd3d_b.jpg%22+width%3D%221024%22+height%3D%22791%22+alt%3D%22Extruder%2520Assembly_zpsofjgcl45%22%3E%3C%2Fa%3E%3Cscript+async+src%3D%22%2F%2Fembedr.flickr.com%2Fassets%2Fclient-code.js%22+charset%3D%22utf-8%22%3E%3C%2Fscript%3E&hash=2838fa9e7a31bb9f4fc3cc6b7033b413)