Build List

Build Author

David E. Flores E.

Views

580

Build Author

David E. Flores E.

Views

580

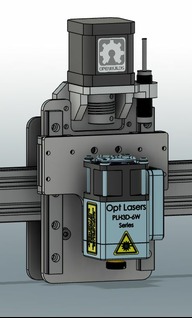

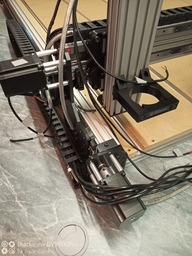

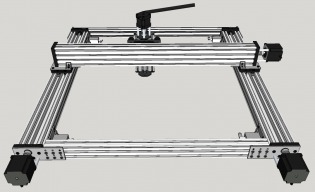

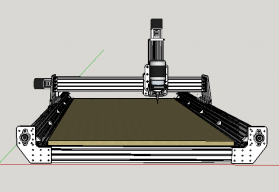

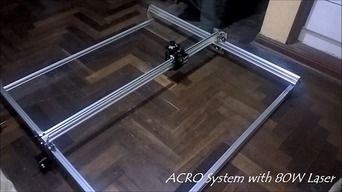

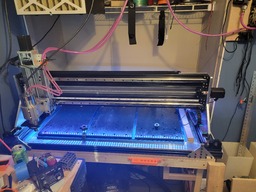

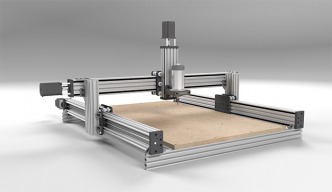

ACRO System w/Laser 80W

This is my version of the OpenBuilds ACRO System CNC, a 1010 version (1000mm x 1000mm). I need this machine to build PCB prototypes within 2-days at maximum. I will try to build PCBs using drill and laser methods...

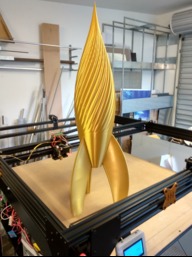

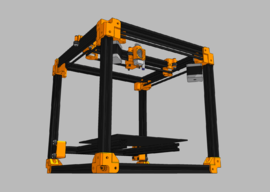

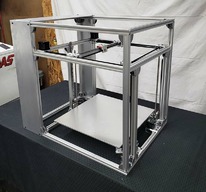

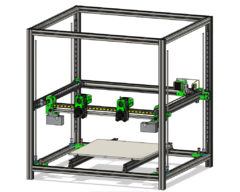

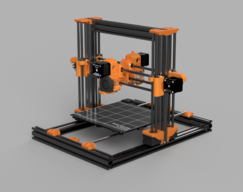

Large 'Double H-Bot' using Openbuilds 2040 v-slot

The aim of this design is to build a simple, cost effective (under $1000) and relatively compact large volume (m3) 3D printer that will use a pellet extruder to create art/design objects using shredded recycled plastics.

Techsoft Roland TS-30 rebuild

Replacing the Electronics and Spindle. Intending to rewire all the buttons and make it into a more modern and easy to use CNC.

Build Author

Keith Davis

Views

20979

Build Author

Keith Davis

Views

20979

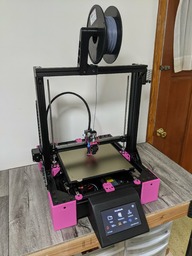

Vulcan MAX

While mimicing the frame platform of the popular Crealiy CR-10 and Ender series, the Vulcan MAX overcomes design weaknesses in both printers. Chief improvements are a more stable, rigid mounting of the Z frame and Z gantry.

Build Author

Troy Joachim

Views

14375

Build Author

Troy Joachim

Views

14375

Sigron IDEX

BNC3D Signax + Voron = Sigron IDEX

Dedicated Compact Rotary Axis Laser Engraver

Compact Dedicated Rotary Axis Laser Engraver

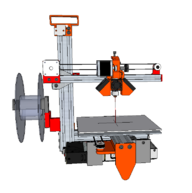

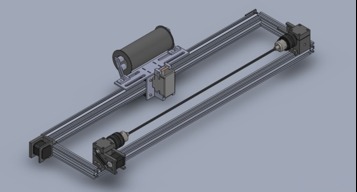

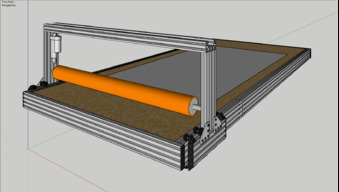

A Rolling Plotter

To build a simple plotter that rolls along the length of large paper, foam core or other flat objects.

Build Author

Elias Ramburger

Views

1697

Build Author

Elias Ramburger

Views

1697

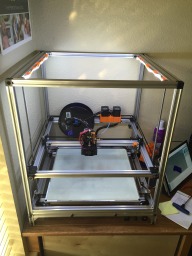

600 volume 3D-Printer

Hello. I build this 600 by 600 printer and hope to share it. I plan to sell custom builds with my website in the middle of this yeahr while making all parts accesibble online for replacements and own builds. My plan was to build a better and more accessible big volume 3d-printer as cheap as possible. I got some inspiration of the ender creality 3, the crazy-Print xyz 300 and the veho 600 tronxy which was simply not relaible and satisfying overal.

Gerber 404 Retrofit

Not sure if the Blackbox X32 is the right option here, just looking for guidance.

Rotary Axis OX Derivitive

A Rotary Axis CNC router based on the OX CNC Router

Build Author

Scott Drake

Views

15977

Build Author

Scott Drake

Views

15977

1500x1000 CNC Router

1500x1000, additional frame stiffening from laser cut Stainless steel bracing plates, Nema 34 motor upgrade and Hiwin 16mm ballscrew additions on the way. Ethernet Smooth stepper control, 2.2kw Water cooled spindle. Schneider atv320 variable speed drive. SICK inductive limit switches, Leadshine Em882S stepper drivers ,1kw 62V supply for Stepper drives

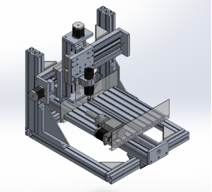

C-beam Machine - Modesty

Modified C-beam Machine. Taller (30 cm) C-beam uprights in gantry, and longer 750 mm frame in Y direction. XL gantry plate on X (and Z?). Y will have additional 700 mm SBR16 rails as extra support and slightly raised bed to fit above stepper motor. Approx. machinable area of 370 x 370 mm.

Build Author

Joe Young

Views

11732

Build Author

Joe Young

Views

11732

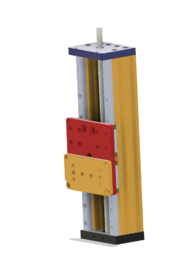

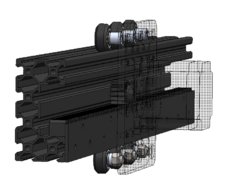

Rack and Pinion (Death to Belts)

Low profile rack and pinion linear actuator design

Build Author

Quentin Karmark

Views

6243

Build Author

Quentin Karmark

Views

6243

Laguna Swift 4X4 CNC mill retrofitted with OpenBuilds

Used Laguna Swift 4X4 CNC mill with Water-cooled Spindle and RichAuto serial pendant retrofitted with OpenBuilds/Blackbox/Interface

Build Author

StrictlyScale

Views

7235

Build Author

StrictlyScale

Views

7235

Lead1010 Build with Enclosure

First time CNC builder puts together a Lead1010 machine.

Build Author

EvanH

Views

1600

Build Author

EvanH

Views

1600

"Hawk" Heavy-duty dual-Z pseudo C-Beam

A compact, strong machine with very high Z clearance, yet can still mill aluminium easily.

"Hirata scrap find" CNC

First CNC and first attempt at building one also, so yeah... good luck to me!

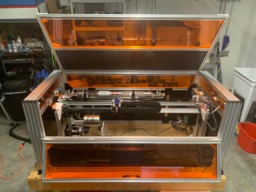

KRE CO2 2x4 Laser

Large Format CO2 Laser Cutter

cnc back stop for brake press

back stop build

Build Author

Troy Proffitt

Views

24419

Build Author

Troy Proffitt

Views

24419

Sphinx Upgraded plates / ballscrews and linear rail

Upgraded Sphinx Cbeam using 3/8 aluminum plates and linear rails / ballscrews

My large machine 48 X 48

This machine is controlled by a Mach3 BOB. I USED Nema 34 stepper motors and a 3kw, water cooled spindle. I’m in the process of adding a vacuum table with 4 zones. I have an X-carve so I use Easel to create G-code for the large machine. I’m currently looking for a way to stabilize the Y-axis. It wiggles a little, so I want to add another linear rail high on both sides.

Build Author

sausagePaws

Views

73642

Build Author

sausagePaws

Views

73642

Embroidery machine with XY belt and pinion drive.

A simple Embroidery machine using an XY belt and pinion drive to drive a hoop under a standard sewing machine. Needle timing, machine power and stepper control are all provided by a PIC processor. A tablet provides the higher level formatting required for communicating with the PIC chip.

Build Author

Mac6986

Views

16085

Build Author

Mac6986

Views

16085

Vinyl Application Roller table

Build progress of custom roller table for applying graphics

Vulcan: 750x1200 V slot 90W Co2 Laser

Tried to get best value and minimal footprint!

Build Author

Kyo

Views

32583

Build Author

Kyo

Views

32583

Sphinx 1050

This is going to be a Sphinx 1050 build. Starting off as a stock kit build using industrial electronics and opensource control software. Mods and upgrades to follow.

Salmon Sphinx 1.0

A tribute build based on Kyo's wonderful CBeam Sphinx. My hope is to improve on that build slightly, but to be honest, I'll probably just screw it up. I'll use this build to publicly document my failures.

Build Author

Rob Taylor

Views

16326

Build Author

Rob Taylor

Views

16326

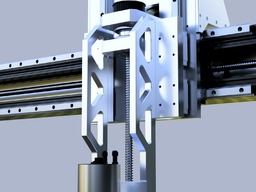

M4: 1510SS Heavy Mk.I

A 1500x1200mm, 20mm rail and 1610 ballscrew, heavy-duty, four-axis gantry machine. As high speed as spindle power MRR will allow for. Approx 4 x 3 x 1ft travels, intermediate size between benchtop and floor-scale units. Aiming at $10-15k machine in the $3k region.

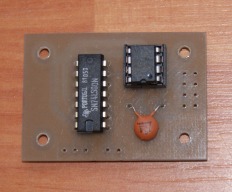

Software speed control of a brushless dc (Bldc) motor from Mach3.

Although this build is typically Mach3 related there is no reason it cannot be adapted for use with any machine control software which provides a PWM spindle control output. As an addition, an option has now been added which will enable the interface to manually control outrunner speed without the need for a PWM signal.

Build Author

that-jim

Views

7609

Build Author

that-jim

Views

7609

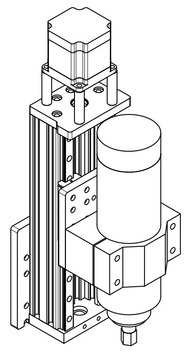

Z-Axis Upgrade For My Sphinx

Z-Axis Upgrade For My Sphinx

Build Author

MattR

Views

17464

Build Author

MattR

Views

17464

Cricut Expressions 2 to ESP32 GRBL Control

A log of my "brain surgery" on a Cricut Expressions 2 to change the control board to something open so that I could cut what I wanted. The ESP32 GRBL board I used has bluetooth and WIFI built-in and was very easy to get working just the way I wanted.

My ACRO Build

An ACRO laser put together with some repurposed and some new parts.

Magnetic CNC Dust Shoe with LED lights and Camera*

Making my own magnetic dust shoe with led lights and a camera. Showing my progress from beginning to now.

Build Author

UltiBots

Views

34993

Build Author

UltiBots

Views

34993

UltiBots CB3030 CNC Router

The UltiBots CB3030 CNC uses C-Beam, V-Slot and an extruded aluminum T-Slot work table. This allows 6mm T-Nuts, step clamps and blocks to secure materials to the work surface. The all metal design makes the use of a mister possible.

Build Author

Yanou Fishel

Views

8823

Build Author

Yanou Fishel

Views

8823

Beefed up Minimill

A beefed up minimill, ready to gnaw on some aluminum! HG15 linear rails, a thick heavy column, bellows and easy fixturing and tramming.

Simpl3rBot

A framing design for cantilever style printers

Denford CNC Resurrection

Denford CNC Mill Update

Y-1200 co2 laser

Y-1200 Build The Y-1200 has a cutting area of 1200 x 600mm and the main chassis has a external size of 1620 x 955 x 450mm. The recommended power output is 60-90W, this can also be increased with the use of an extension box. designed by furtherfabrication ROB CHESNEY FREELANCE INDUSTRIAL DESIGNER.

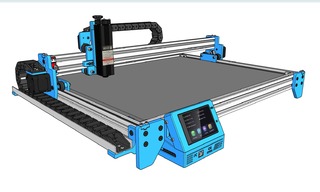

Custom 4x4 CNC

I started designing and ordering parts for this build back in Oct 2021. Unfortunately life got in the way and I had to sideline the project to deal with more important projects. I am now back working on this project full time. I originally was building a MPCNC on this torsion box platform I built but quickly realized how difficult it would be to produce anything with good accuracy. So I decided to design my own CNC that would be more robust and accurate.

KillerBee 1515 customized

Killerbee 1515 with modifications.

Build Author

Cam Garrett

Views

2549

Build Author

Cam Garrett

Views

2549

Sturdy Motorized Photographic Copy Stand

i would like to build a sturdy motorized photographic copy stand. i have hobbled together a hand crank version using a used umbrella pole but it is not suitable as it is awkward and wobbly.

Build Author

OpenBuilds

Views

3488

Build Author

OpenBuilds

Views

3488

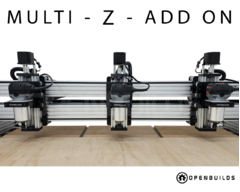

Multi Z LEAD Machine Addon

The Multi Z adds multiple Z axis to a LEAD CNC Machine allowing it to cut and carve 2 to 3 times the amount of projects in the tame it takes to make just one

Photogrammetry 3d Scanner

A mid-sized version of a Photogrammetry 3D Scanner.

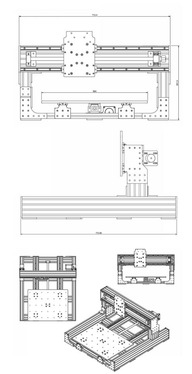

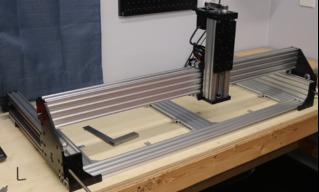

Fixed Gantry CNC Router

A fixed gantry router using OpenBuilds control and electronics.

Build Author

deltajegga

Views

8520

Build Author

deltajegga

Views

8520

THE delta

probably as big as you'd want it...

CNC built, work in progress, fail

2x4 cutting area, enclosed with dust collection mainly built out of wood.

Budget friendly starter build

DIY CO2 laser build. Budget friendly, 2020 T/V-slot profiles and scalability.

Lead 1010 First time build

First time build of the Lead 1010 CNC with the High Z add on.

Build Author

boutrous

Views

7675

Build Author

boutrous

Views

7675

Laser Rotary Attachment

Build Summary updated after parts list completed

Filament winder ( carbon fiber )

Carbon fiber filament winder

Fixed Gantry Easy Assembly

Fixed Gantry CNC with good accuracy and rigidity but for a higher price than the usual CNC's on the site.

Dedicated Rotary Laser Made from Scrap and Spares

A clone of https://openbuilds.com/builds/dedicated-compact-rotary-axis-laser-engraver.10204/

Custom 40W Laser Cutter

So this is my custom 40W build. I wanted to make another laser similar to the one I built but a lot smaller and an all in one system so that if I ever decide to do a farmers market or something similar, I wanted to be able to put the laser on the back of the car and drive to whatever location. I think it's going to work. It will be see-through with lights and screens eveywhere. The lights alone should attract people like flies. That's the plan anyway.

CoreXY W/ Fixed Build Plate & Enclosure

Building a Core XY printer with a fixed build plate from off the shelf parts.

Build Author

Jasont

Views

2720

Build Author

Jasont

Views

2720

MY first CNC build

my first cnc build using the lead 1010 to build bigger and better!!

Build Author

Sonny Lowe

Views

5418

Build Author

Sonny Lowe

Views

5418

MakerSL MSL-65 Manual Coffee Grinder Stand

I know this build is a little off category here at OB, but I wanted to share it with the community (as well as other coffee lovers) and show however vast the possibilities are when OB hardware is involved. This is a powered stand intended to operate a manual coffee grinder. It is compact, light, portable and uses simple drive components (B&D Cordless Screwdriver). I will post two version, V-1 (Beginner skill level ) and V-2 (Intermediate skill level). Both accomplish the same results.

Sphinx 55 on MGN12 linear rails

My machine is a combination of the Openbuilds Sphinx 55, MGN12 linear rails knockoffs and custom made plates made by Chris Laidlaw

THE BIG GREEN MACHINE

1500*1500*1900 (xyz) Biocomposite Pellet 3D printer

3D printer for printing Clay/Paste

I designed this 3D printer from scratch for my mechanical engineering capstone project. It's made for printing clay but should be able to print any paste material. The clay extruder system could be easily modified to work with almost any 3D printer. The printer is approximately the same size as an Ender 3.

Build Author

Jason @ MCC

Views

9675

Build Author

Jason @ MCC

Views

9675

QueenBee Pro CNC Router and Lathe

A 1000x1500mm QueenBee Pro with a 4th Axis Rotary attachment/Lathe Bed.

Build Author

nc3dpw

Views

21020

Build Author

nc3dpw

Views

21020

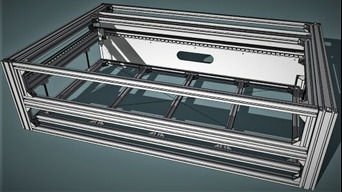

(Portable) Large Format 3d Printer 4ft square frame. Build Volume 36in x 36in x 36in

Large format printer build based off successful small Corexy. I figured it could be scaled to large format and be portable. Portable meaning by removing a few pieces it could effectively be rotated out of a standard door frame.

Build Author

JCPhlux

Views

24477

Build Author

JCPhlux

Views

24477

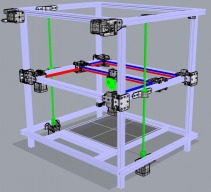

Tesseract

Large Core XY 3d Printer W/fixed build plate

2 Axis Lathe cutter

Rubber company use as a lathe cutter for accurate cuts compared to hand cutting.

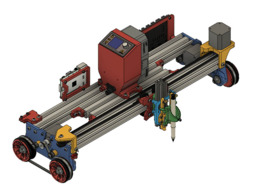

Dragon Portable CNC Plasma Cutter

A small portable CNC Plasma Cutter with some unique features

Build Author

viktop

Views

21328

Build Author

viktop

Views

21328

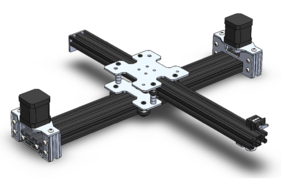

Simple Cnc System (arduino Grbl)

Arduino powered simple CNC system using GRBL firmware. Designed to give the most function using the very least number of parts at the lowest price.

Build Author

ahayden

Views

25318

Build Author

ahayden

Views

25318

C-Beam Prefab Untitled

The C-Beam Prefab Untitled is designed as the cartesian compliment to the C-Beam XL. With the exception of requiring a couple more 1000mm C-Beams and lead screws, the build requires a minimum of additional parts. The primary intention of the build is to maximize the cutting envelope while still staying within the sweet spot for C-beam rigidity. This design can easily be modified and allows for further custom structural components to be cut with the initial build platform.

C-beam charmer

Double C-beam Y axis 500mm., Double 2080 X axis 600mm. , C-beam Z axis 250mm, TB-6600 drivers, MKS-DLC32v2 GRBL w/wi-fi and blue tooth

Build Author

Troy Joachim

Views

15764

Build Author

Troy Joachim

Views

15764

Prusa i3 Bear IDEX

Remix of the Prusa i3 Bear with added IDEX

Build Author

James Archer

Views

12351

Build Author

James Archer

Views

12351

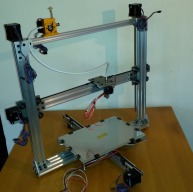

Archer - An extendable all metal 3D printer

This is an all metal build using OpenBuilds V-Slot linear rails to produce a high quality and cost effective 3D printer. The printer is designed to be scalable for your desired build area and can utilize high quality hotends with 16mm groove mounts such as E3D.

W|W plasma/drag knife 1500x1500 (floating head & z-axis)

Step by step designing and implementing of my plasma approach

Build Author

blterry1

Views

16680

Build Author

blterry1

Views

16680

The Beeline CNC

Here are the instructions to build the Beeline custom CNC router table.

3D Turn Table Scanner

My attempt at a 3D scanner. Still trying to convince myself it will work.

New Workbee Z Axis

Hopefully an upgrade of the Z axis of the Workbee.

V-Slot Miter Saw Stop

A quick and simple saw stop build.

Travel Printer

Build using standard parts as much as possible, Open Builds etc. To keep printer usable for more materials will be trying a heated bed with rotary elec union for the thermistor and power.

ACME OX (A Lead Screw Driven Ox Derivative (850x1500))

Another build based on the original OX design with a cutting area will be about 26" (680mm) x 50" (1300mm) and driven by lead screws.

SolidCore CoreXY

All metal CoreXY 3D Printer Design with triple z, kinematic bed, and scalable corexy mechanism.

Ike:Laser

A 2 axis laser engraving machine, with a manual Z axis.

Shawn's Workbee 1510

Shawn's adventure in assembling and customizing the Openbuild's version of the 1500x1000 Workbee.

Build Author

Jay Almers

Views

6509

Build Author

Jay Almers

Views

6509

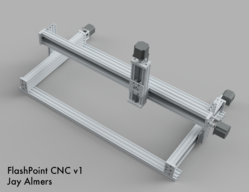

FlashPoint CNC v1: 500mm x 1000mm 3-Axis CNC Router

My build is based on many different builds but pieced together into a unit specifically to suit my needs. The footprint, without motors, is around 500mm x 1000mm with a gantry height of around 250mm. I used a combination of C-Beam, for the linear transmission, and V-Slot for the base and gantry supports. Forged angle connectors were used for attachment and I utilized the C-Beam gantry cart kits with anti-backlash blocks for both Y axes, the X axis, and Z axis.

Ooznest Ox with 3D Printed Gantry Plates

Ooznest Ox with gantry plates and end caps 3D printed in ABS rather than aluminum.

C-Beam XXLarge "Tank"

This is a modified build C-Beam XLarge. 1000mm C-Beam used for X and Y axis, and the Y Axis moves the X bridge, not the material being worked.

The RAT. A form ply and aluminium hybrid.

A hybrid of form ply and aluminium. 835x1260x100mm working envelope.

Promoveo Study Builds

Promoteo Build

7 Axis Camera Slider with Telescoping Vertical Lift

A six axis camera slider with a 7th LIFT axis added!

Build Author

Dave420

Views

13205

Build Author

Dave420

Views

13205

OpenBuilds C-beam 15mm belt on 1500mm C-Beam.

OpenBuilds C-beam 15mm belt on 1500mm C-Beam.

Build Author

Frank Gore

Views

7455

Build Author

Frank Gore

Views

7455

Kossel Extreme

A custom Delta printer for large projects with any filament that still retains speed and accuracy, all within a 15 amp/110VAC power budget. Based on Johann's Mini Kossel design.

Build Author

BeTrue3D

Views

20349

Build Author

BeTrue3D

Views

20349

BeTrue3D Printer

High Quality CoreXY with focus on quality and optimized printarea versus physical size of the printer.

ME - Laser CNC

Build of a small laser engraver using V-slot profiles and 3d printed parts

Build Author

pedrofernandez

Views

16240

Build Author

pedrofernandez

Views

16240

Co2 Laser Cutter/Engraver Rotary Attachment

Vslot rail system at work again, laser cutter/engraver rotary device for cylindrical objects .

The Franken Rotor

Yes another K40 Franken machine dedicated for round objects,,,

Build Author

M1dn1ghtN1nj4

Views

8179

Build Author

M1dn1ghtN1nj4

Views

8179

The Beast

This is a heavily modified system based on the RatRig V-Cast. Lots of personal touches, and a LOT more to come!

Mini lathe CNC Conversion - Work in progress

My on going build of CNC Mini Lathe

Build Author

sgspenceley

Views

186379

Build Author

sgspenceley

Views

186379

Linear Rail CNC Machines

A CNC build using linear rails & lead screws.

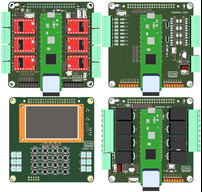

M10CUBE PICO CNC. A Universal Controller

An attempt is to be a Unified Modular Controller based on M10CUBE platform. For GRBLHAL and MARLINHAL applications. HAL porting is under way 1 - WIZnet Pico Clone W5100S-EVB-Pico 2 v- 6 X StepStick. Not sure about the sixth driver, (Pico pins limitation) . External connectors for larger drivers 3 - Opto - isolated spindle PWM. 4 - HMI 5 - I/O on diferent modules and Ethernet 10MBPS communication. Patches will be written to GRBLHAL for Ethernet I/Os (Interrupted).

Build Author

Edgar Mata

Views

21040

Build Author

Edgar Mata

Views

21040

ME - Core XY 3d printer

I wanted to make my own Voron, so I made my own Voron,

Build Author

T4Concepts

Views

72710

Build Author

T4Concepts

Views

72710

WorkBee CNC build - My honest opinion, tips and help

My main goal for my build is to have a machine that is capable of profiling and help me in my designs, for the manufacture of custom automotive headlights.

Build Author

Glenn Weston

Views

9476

Build Author

Glenn Weston

Views

9476

"AcroCadabra" My Acro Laser built with my C-Beam XL

Well I built a C-Beam XL around a year ago, I am still learning things as I make stuff with it, it has been quite a wonderful learning experience. Now I have gained enough confidence and knowhow to Mill the required Plates to build an Acro Laser System using the Acro Laser Sketchup Model. I have pulled the Model apart in Sketchup, isolated the Plates and generated the G-Code to cut/Mill the plates. I have used Sketchucam to generate the G-Code. I Use Mach3 on my C-Beam XL to Mill.

Draw bot core xy

In the design stage. Help guide.

Robo Morten

A horizontal-router CNC using openbuilds parts geared toward routing out mortise and tenon joinery; or any other end grain work on wood.