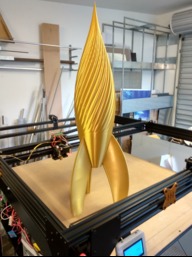

The aim of this design is to build a simple, cost effective (under $1000) and relatively compact large volume (m3) 3D printer that will use a pellet extruder to create art/design objects using shredded recycled plastics.

I decided on the H-belt configuration but using two sets of motors and belts to eliminate gantry racking, reduce belt 'driven length' and keep the motor size down (all motors are NEMA17). This belt arrangement is superior to a twisted core-xy. It is especially suited to larger builds - each of the H belts is over 7.2m in length.

Nozzle diameters would range from 0.8 - 2.5mm.

The Openbuilds v-slot extrusion, v-wheels and mini-v wheels are the foundation of the frame/linear rail/gantry design. I experimented with various profiles (2020, 2040, 2060, 2080 and C-beam) and configurations in CAD but settled on the 2040 as a singular extrusion profile throughout the design.

The z-gantry is also belt driven using two stepper motors with planetary gearboxes.

Outside Dimensions using 1200mm cut lengths of 2040; x=1200mm y=1300 z= 1380

Build Volume; x=1000mm y=1050 z= 1100

Large 'Double H-Bot' using Openbuilds 2040 v-slot

Build in 'H-Bot and Core XY' published by Peter Stoneham, Sep 17, 2019.

The aim of this design is to build a simple, cost effective (under $1000) and relatively compact large volume (m3) 3D printer that will use a pellet extruder to create art/design objects using shredded recycled plastics.

-

-

-

- Build Progress:

-

- Build in Progress...

Attached Files:

EugenePo, Richard148, Carston and 19 others like this. -

-

Build Author Peter Stoneham, Find all builds by Peter Stoneham

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution - CC BY

Reason for this Build

To recycling plastic waste into art/design objects.Inspired by

various builds and forums - not one in particular