Since the laser's basically done at this point and the need for a large format multi-material machine has come to the fore, it's time to pull Machine #4's timeline forward and get on with it.

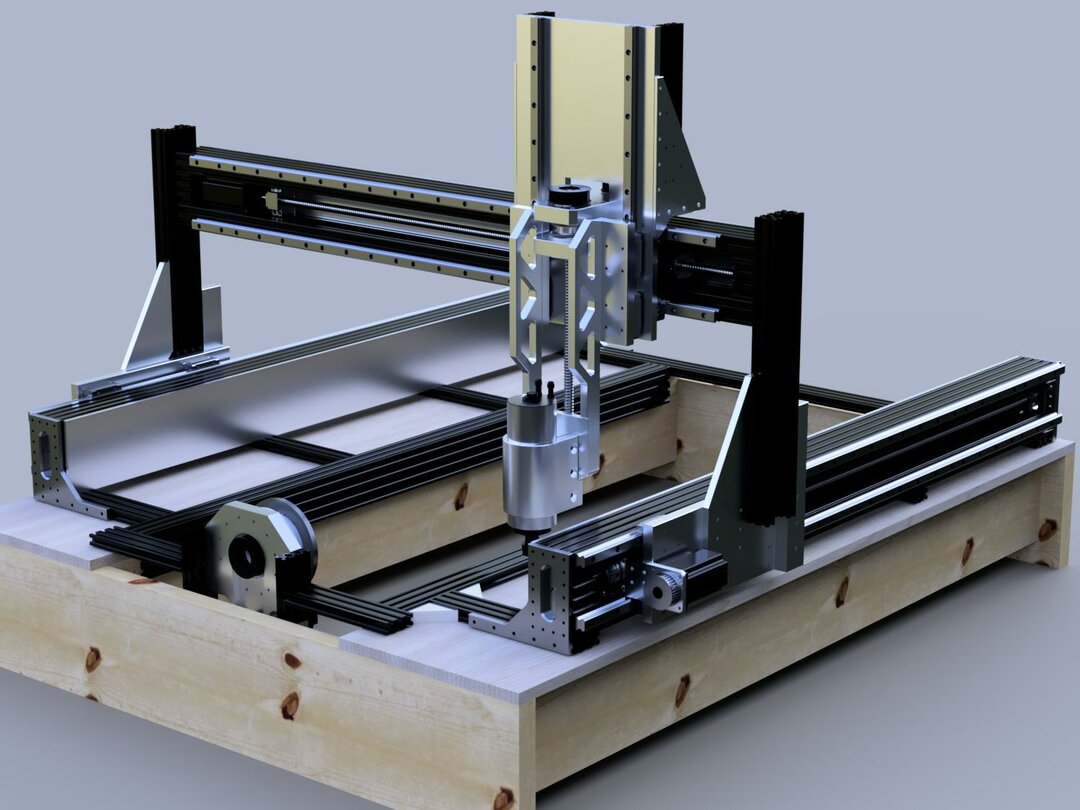

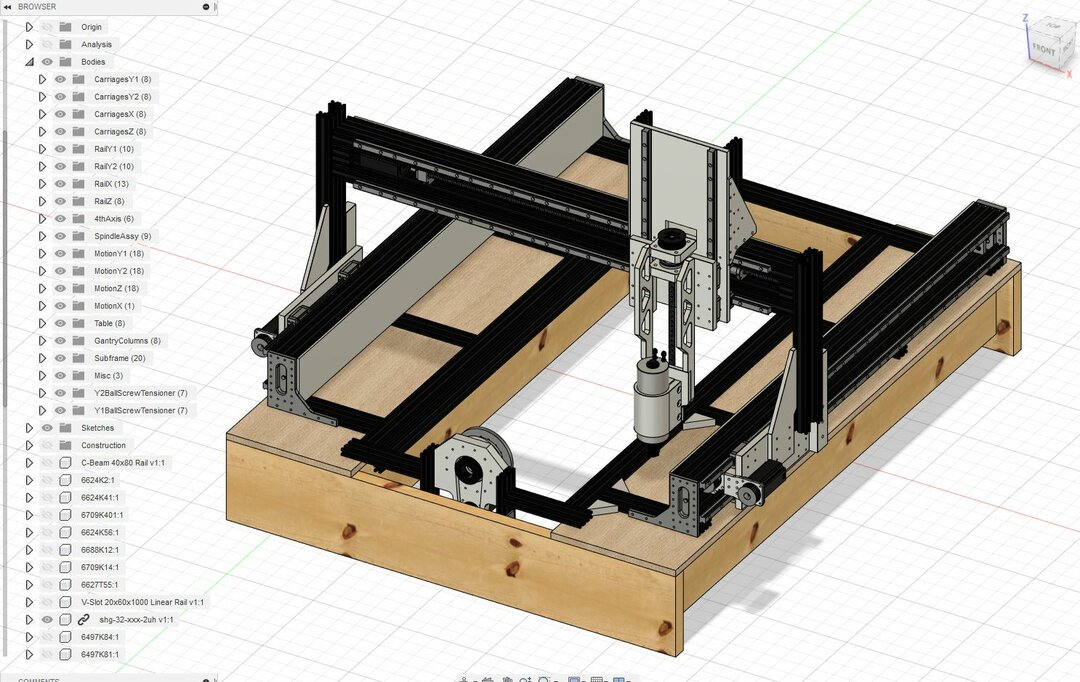

First I built it in Fusion 360 so I could get a sense of the size and number of parts to order, and figure out the parts that needed figuring out, like the rotating nut assembly, ballscrew tensioning systems, etc.

- The main view of the machine.

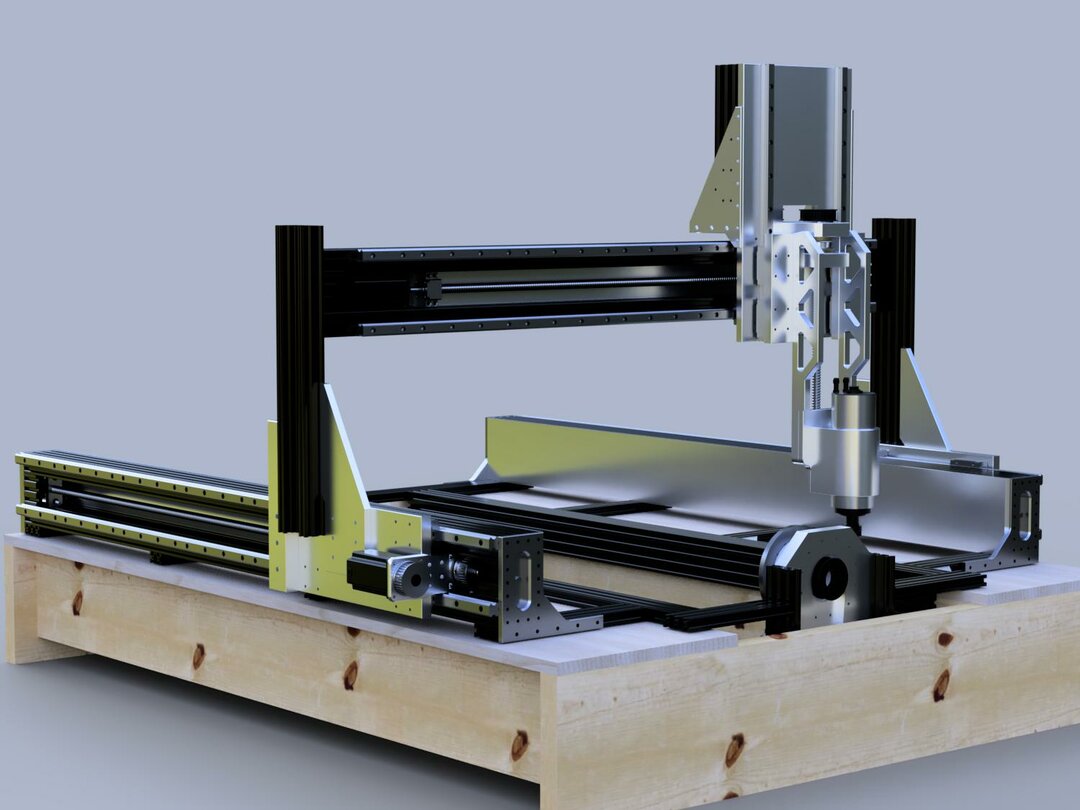

- Other side. It's symmetrical!

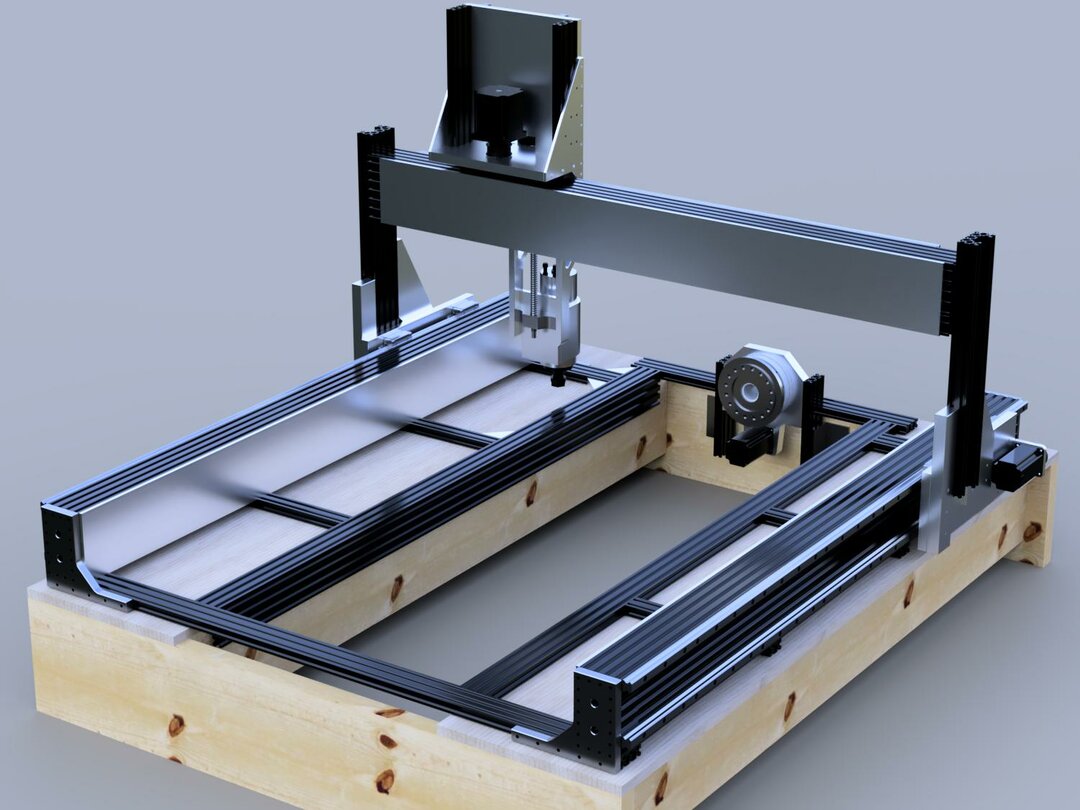

- View from back left, showing NEMA 34 Z motor and 4th axis assembly. The rails tying it into the main frame are pretty much placeholders for now, I'll work more on that later when I have some offcut pieces to play with.

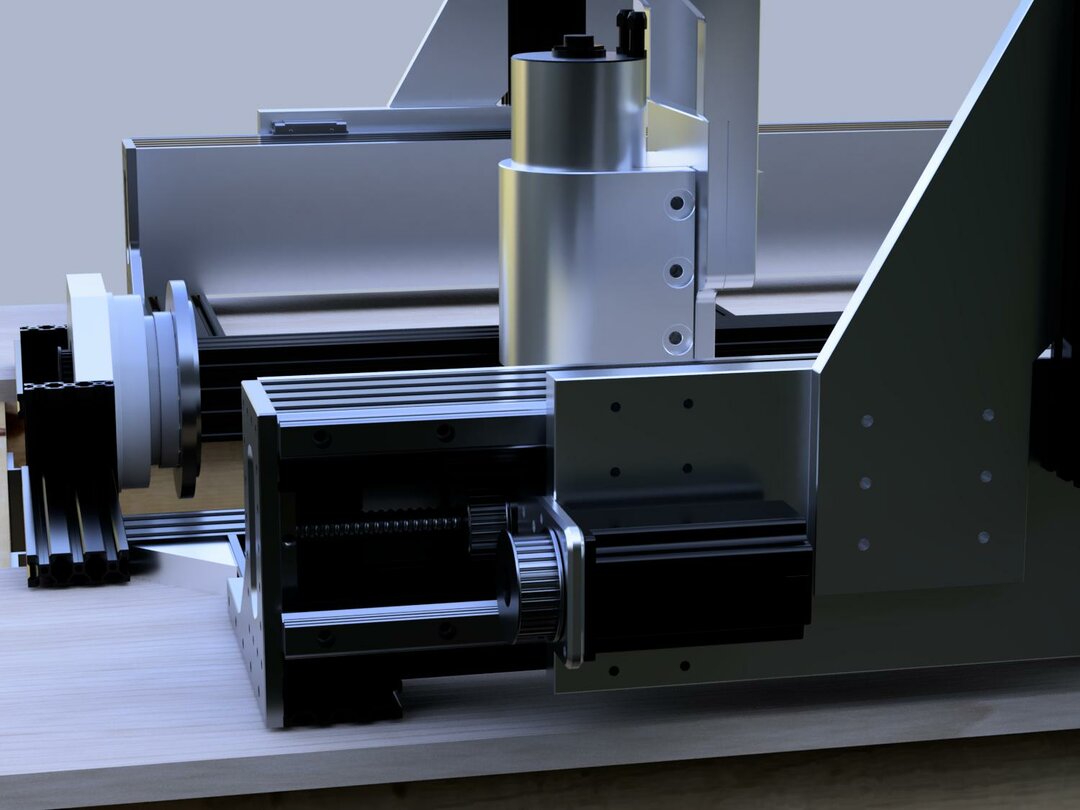

- Y axis rotating nut NEMA 24 (60mm) motor- closed-loop steppers for now, servos later. Hopefully these are powerful enough, I might need to upgrade to NEMA 34 motors on the Y but 24's are pretty close in power (3-4Nm)

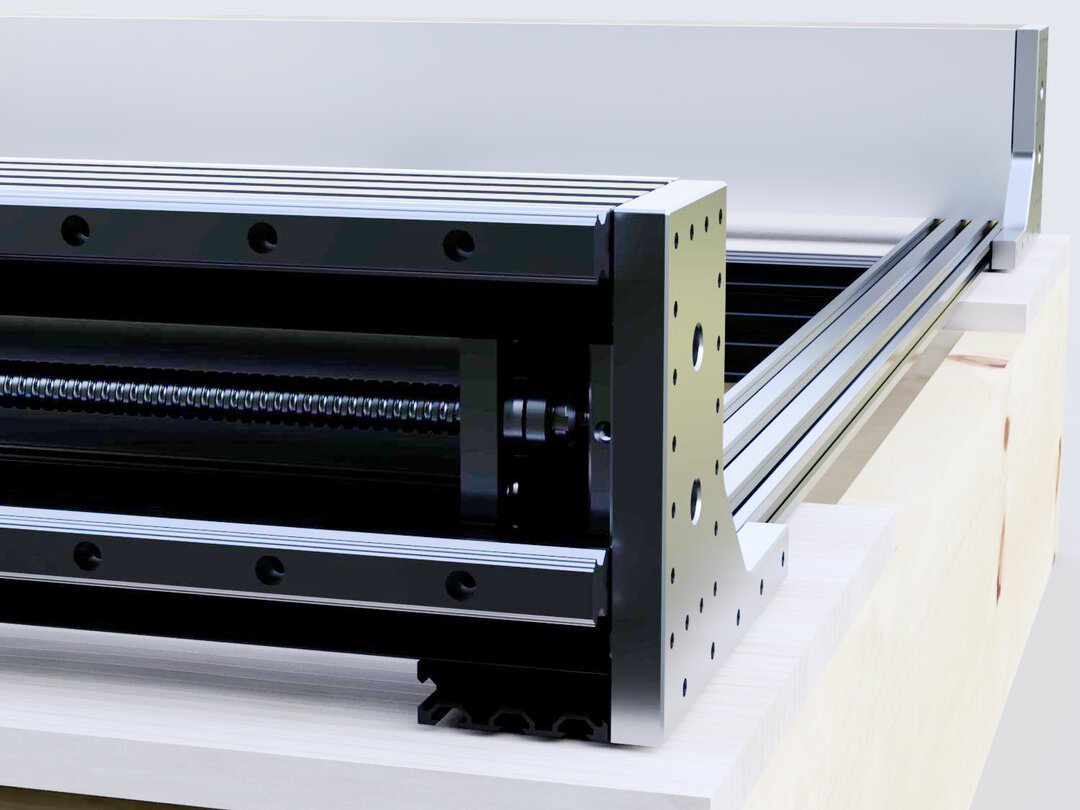

- Ball screw tensioning system. Two plates, one floating, which pulls against Belleville washers where the bearing mount would normally go. Since it's stationary screws and whip isn't a concern, this is more for consistency, thermal performance. It should also allow the screws to be tightened in such a way to actually match their exact pitch to each other, or at least remove any egregious disparities.

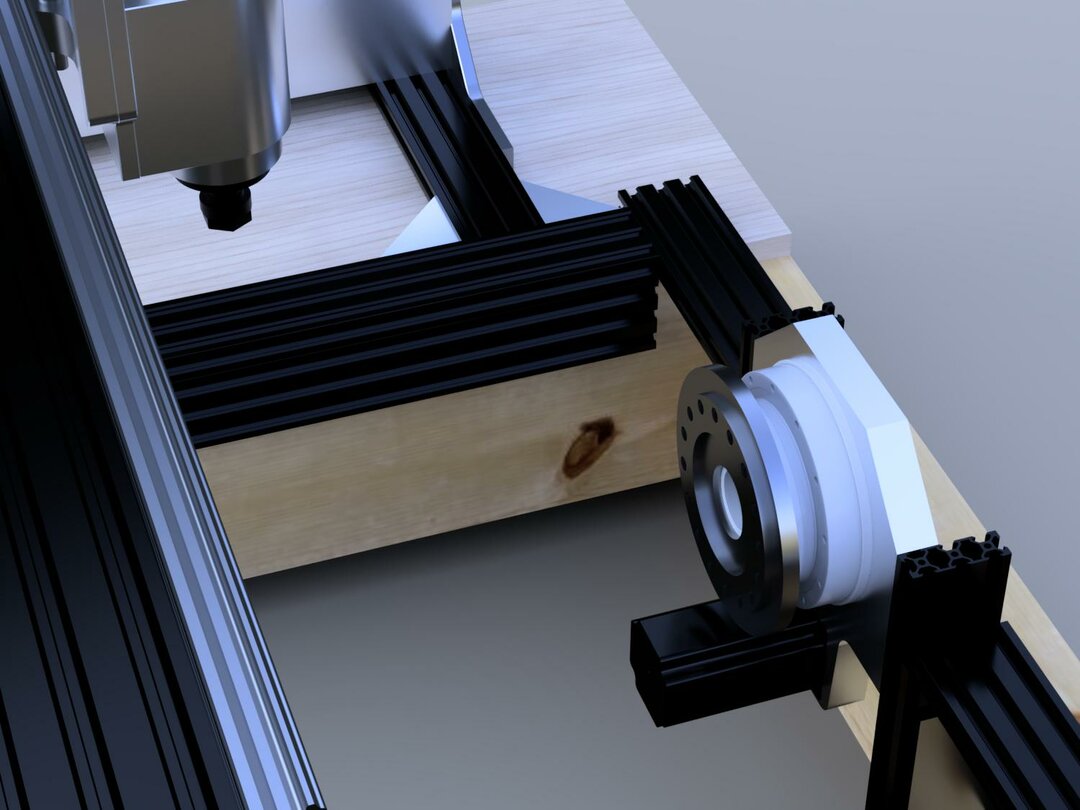

- Back side of custom spindle clamp, and 4th axis assembly: NEMA 24, pulleys (rear, not seen), mounting plate, Harmonic Drive SHG-32-80-2UH reducer, and chuck backplate for standard K11-160 6" 3-jaw chuck.

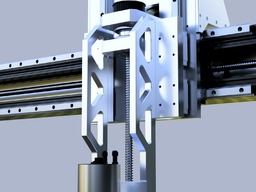

- Z spindle beams and rotating nut assembly. I wouldn't be surprised if these arms needed redesigning at some point, but I think they're 5/8" or 3/4" plate so it should probably be fine as long as there's "only" a 2.2kW spindle on here.

- Y axis rotating nut assembly. A little trickier than the Z axis due to space constraints, but with 60mm spacing between the C-Beams, there's right around 72mm diagonally between corners. Enough to squeeze in some nice beefy 32007 tapered roller bearings!

- That's a lotta parts! Took me a couple weeks or so to finish this thing. Nothing's jointed either, just placed.

- Since it may be an FAQ, here's the section of the rotating nut assembly. Y is the same, but with different shaped plates. The top-hat "spindle" in the middle will be 12L14, to give me the best chance at turning it as precisely as possible. It's also a far stronger steel than I realised, so it should be good. Z will probably be a double-ballnut just to be safe, I got sent a 1610 Z screw instead of the 1605 I requested so I have to pick a replacement out anyway, and might go for the upgrade.

This is it for now. I have the large C-Beam, rails and screws, one motor, some alu plate, materials for one rotating nut, etc etc. Working on acquiring the rest at the minute, so this will get updated as I go.

How much of this can be made on the mill and lathe (machines #2 and #1 respectively, for those wondering about the nomenclature) and how much of it is large enough to have to be bootstrapped once this thing's moving, I'm not 100% sure yet. I tried to reduce part size where possible to fit into the mill's ~5.5 x 13" envelope.

Since I'm planning on doing the final laser video here shortly, this may end up being a video series too, since it's definitely not a straightforward hobbyist build that people have seen a bunch of times before. We'll see.

Controller is currently anticipated to be LinuxCNC due to the 4th axis. $40 i3/4GB Dell Optiplex box from eBay like usual, Mesa 6i25/7i76 combo likely, unless the 7i76e requires less messing about in setup than I've heard before. We'll see. 48V motor drive system, 24V ancillary system, including limits (5V limit noise is annoying). 2.2kW spindle as mentioned, 4kW VFD for overhead room/upgrades. A 3kW ISO20 ATC spindle would be a very welcome upgrade down the line.

M4: 1510SS Heavy Mk.I

Build in 'Cartesian Style CNC' published by Rob Taylor, Aug 22, 2020.

A 1500x1200mm, 20mm rail and 1610 ballscrew, heavy-duty, four-axis gantry machine. As high speed as spindle power MRR will allow for. Approx 4 x 3 x 1ft travels, intermediate size between benchtop and floor-scale units. Aiming at $10-15k machine in the $3k region.

-

-

-

- Build Progress:

-

- Build in Progress...

Robert G Simmons, Nick Haury, james lafountain and 33 others like this. -

-

Build Author Rob Taylor, Find all builds by Rob Taylor

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution Share Alike - CC BY SA

Reason for this Build

The need for a large format machine in the home machine shop, the need for a large format machine in a prop shop, the utility of a large format machine for household purposes... Many reasons.