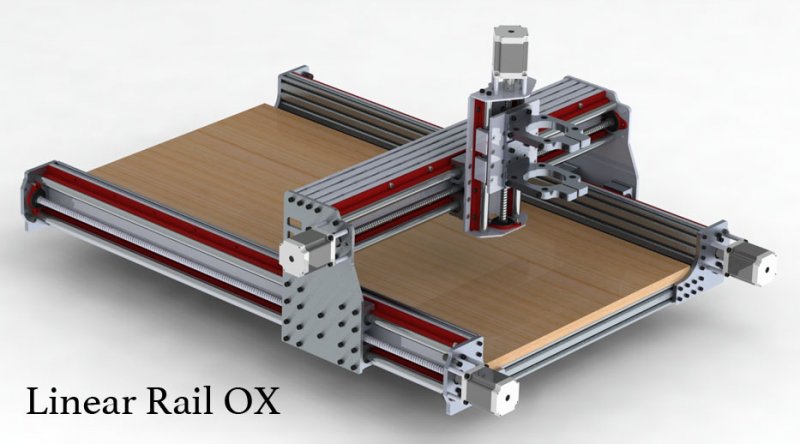

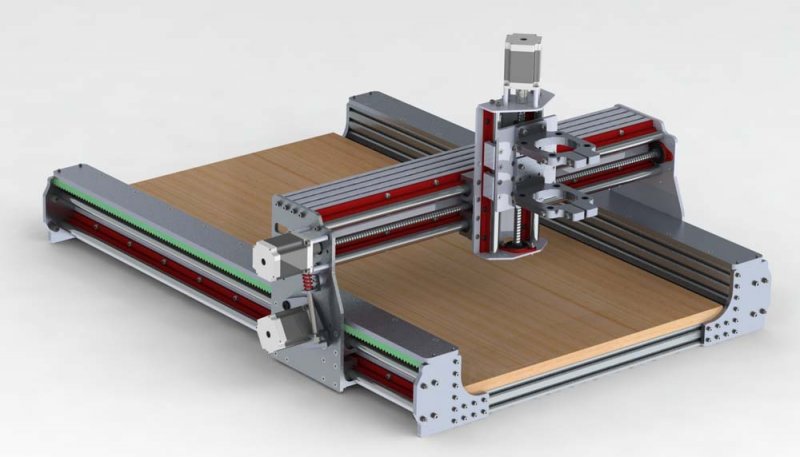

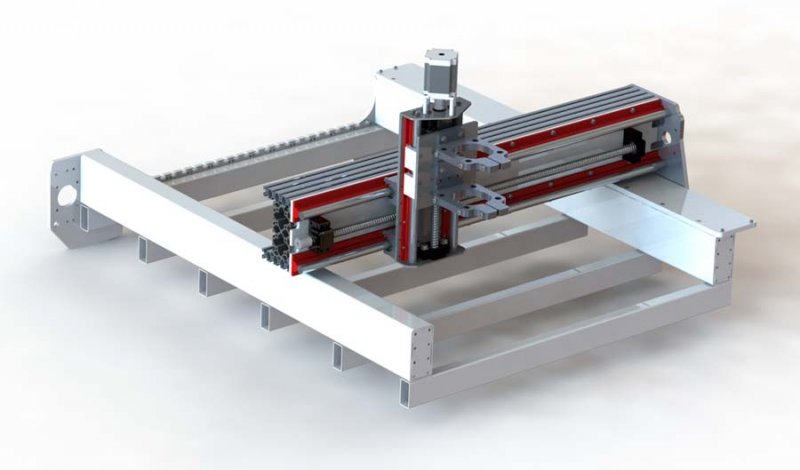

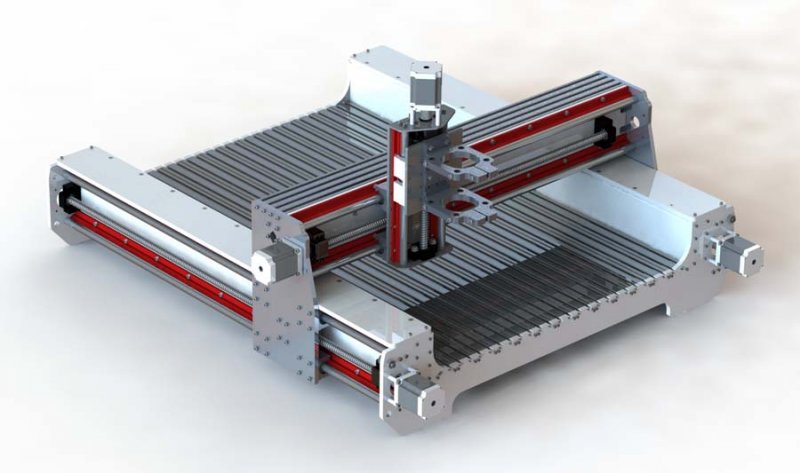

I really enjoyed building my first aluminium OX, so I have decided to dramatically update the original version using linear rails and leadscrews on all axis.

My first concept design was to re-use as many of the original OX components but as you will see my design process evolved away from the open builds parts because I want a really strong and accurate CNC machine which can cut aluminium accurately.

What you will notice when designing a better machine as you upgrade one part of the machine other parts also need revisions. It's a process and you need to know when to stop improving and start building!

It's easy to replace the extreme wheels for linear bearings from China, it's easy to replace the belt drive for acme lead screws, then you start looking at the X, Y & Z axis beams and you come to the point of saying. IF I'm going to the expense to machine new plates, add linear bearings and lead screws it's time to go for stronger & stiffer beams. Hence my departure from OpenBuilds parts.

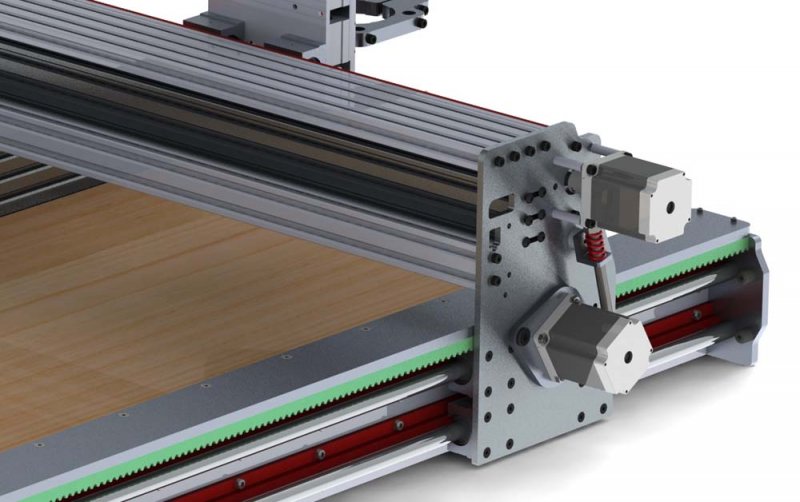

Below shows the original open build extrusions strengthed with 1/4" plates to mount closed linear rails from China. This approach will work nicely for very little additional cost compared to extreme wheels.

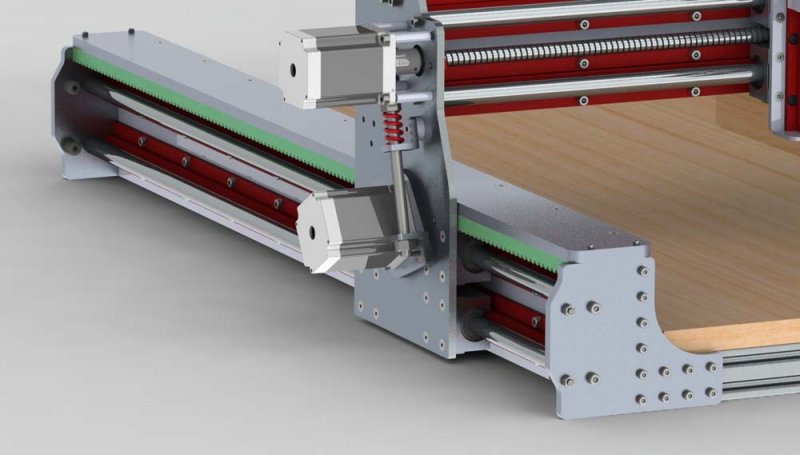

I also decide to design a Y axis rack & pinion variation based on the ideas in the Strong Ox build.

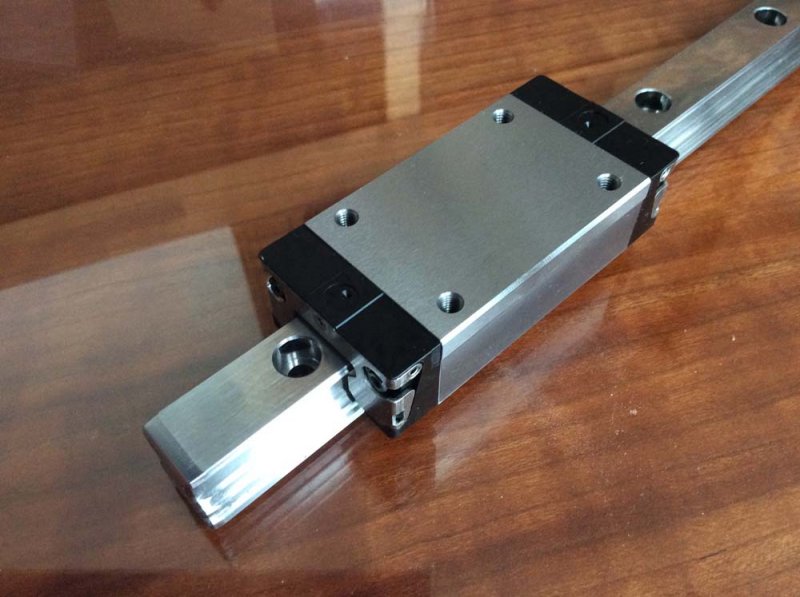

My first set of linear bearings arrived from China, quality is very good. Now they are in "hand" SBR16 are a good size for the X, Y, & Z axis. Bearings are very nicely made with go good dust shields.

Shafts are both very straight, one of the mounting blocks has a "slight" twist along it's length but this will be removed when bolted down.

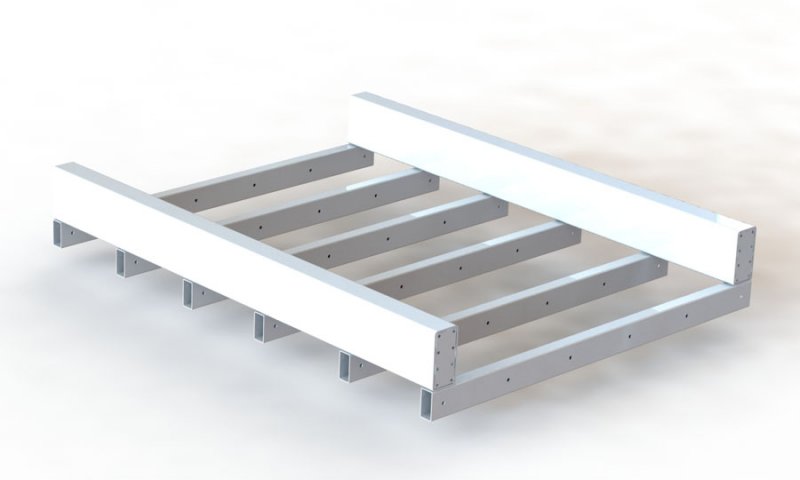

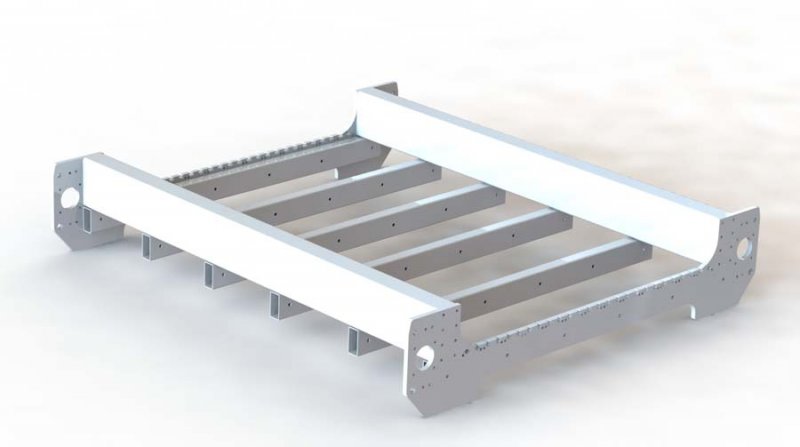

While waiting for parts to arrive, I have decided to modify me original OX to use the 5 start acme lead screws and build a second totally new machine which will use very few open build parts. I have a fabrication and welding background so decided to prototype a new machine using rolled steel tube and welding them together.

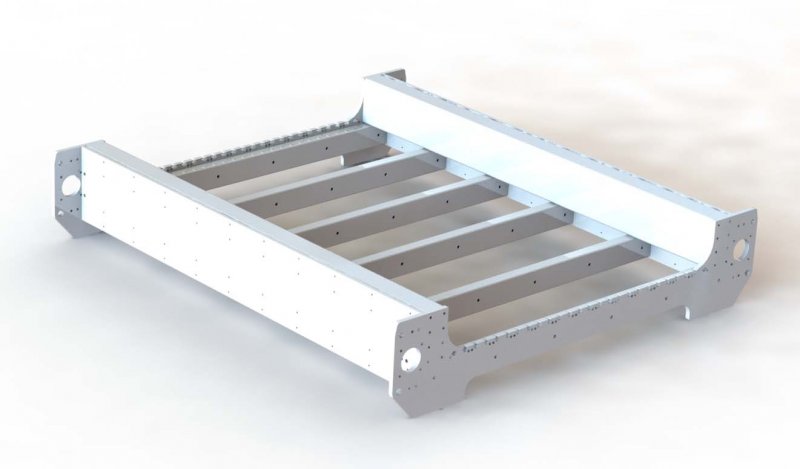

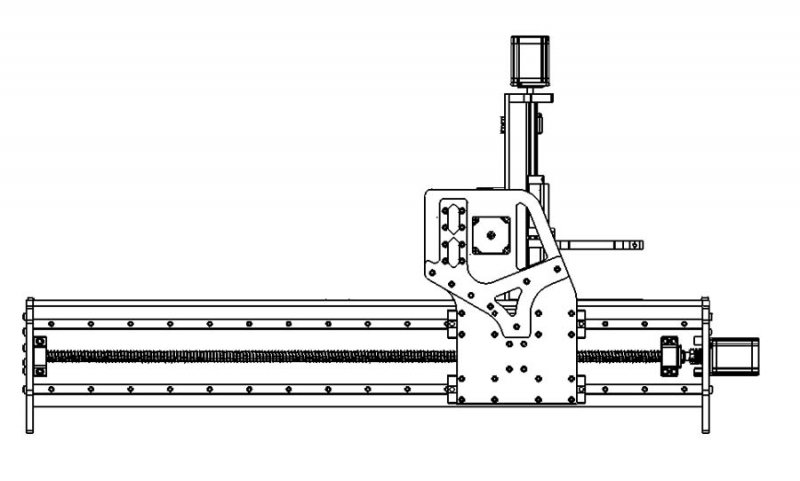

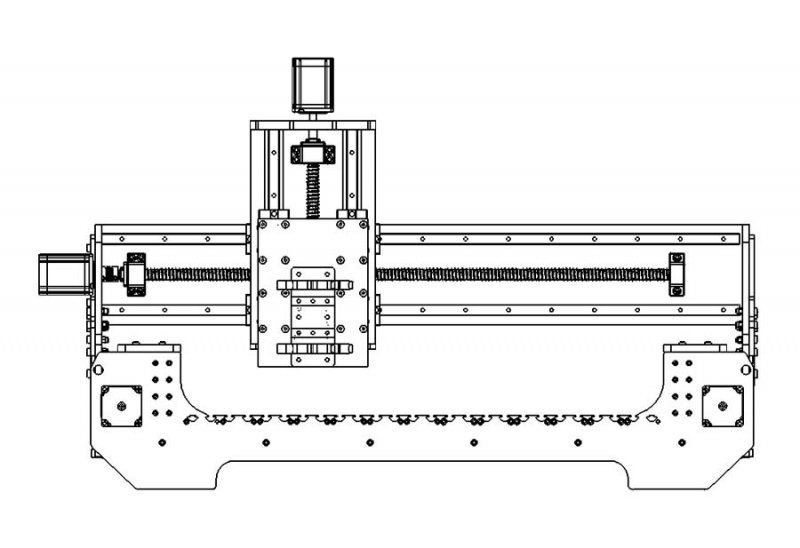

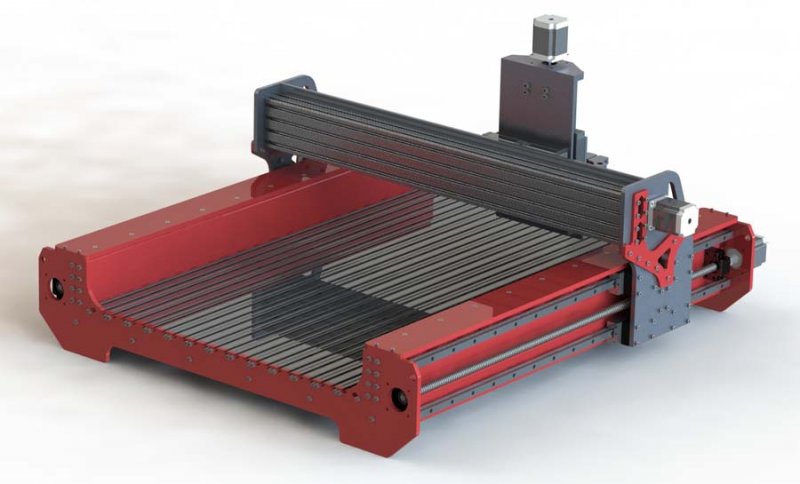

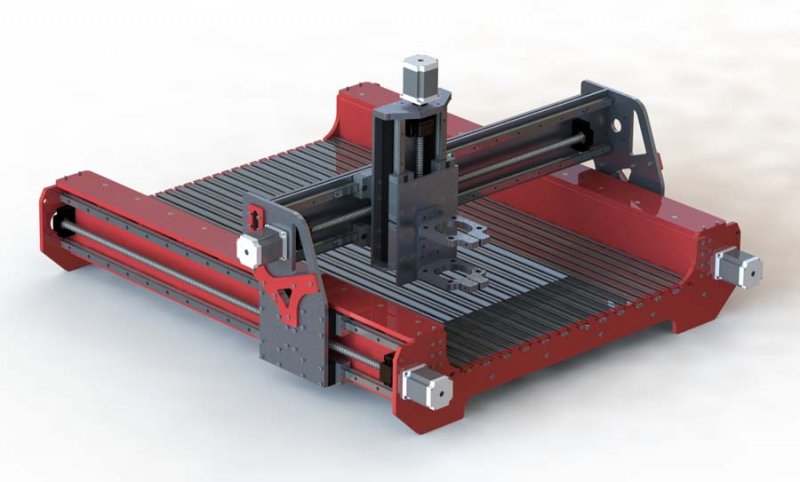

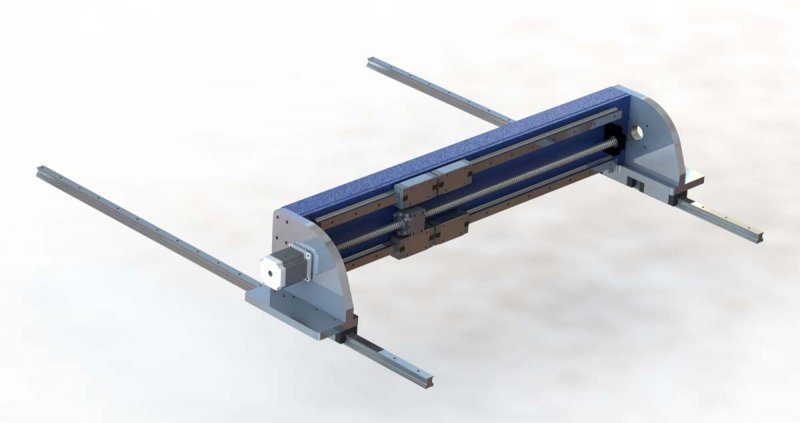

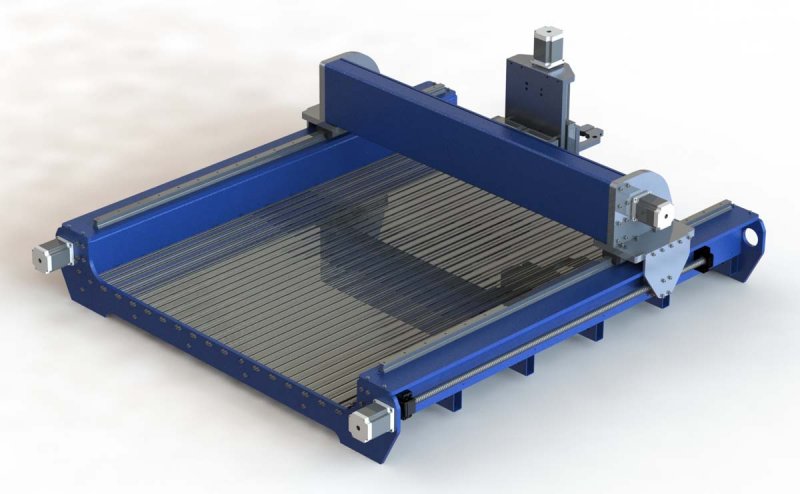

The main frame of the second machine will be welded together as shown below.

Next I will have some 1/2" mild steel end plates laser cut, these will be bolted to the tubes. I want a machine with standard T-Slot hold down base so this is already built into the end plate design

Now add some 1/4" side mounting plates for the linear bearings & ball screws. The separate mounting plates will be bolted into the rectangular tubes so shims can be used if required! When welding it's hard if not impossible to get two perfect parallel & straight faces!

I should now have an extremely strong and solid steel frame with zero flex even under heavy cutting loads.

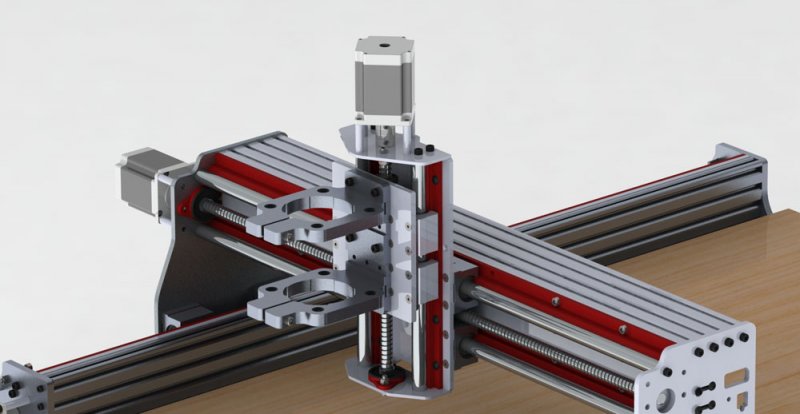

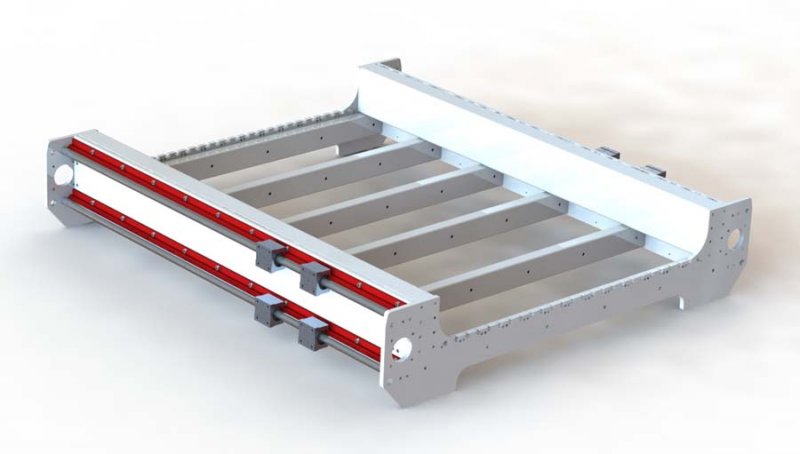

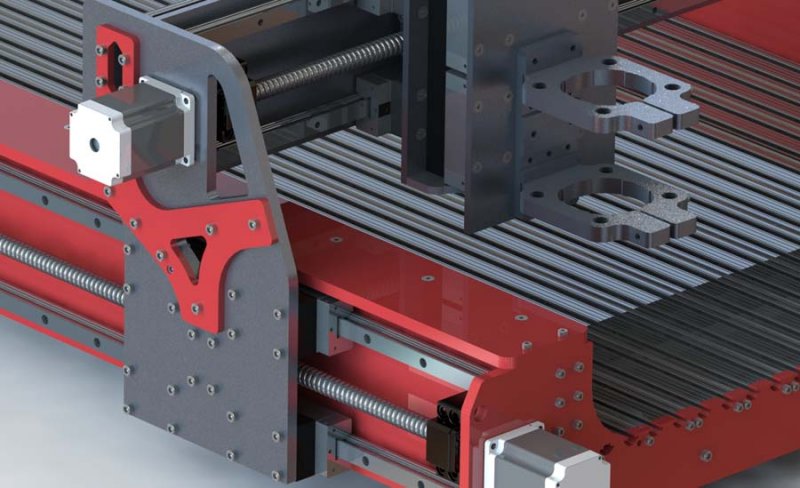

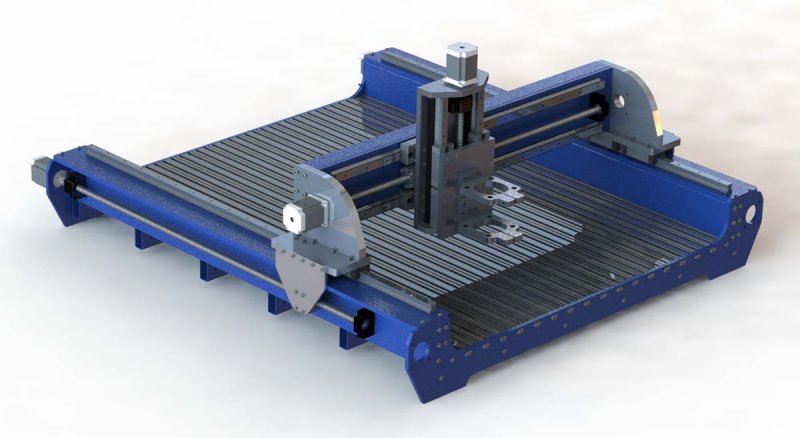

Now add linear bearings.

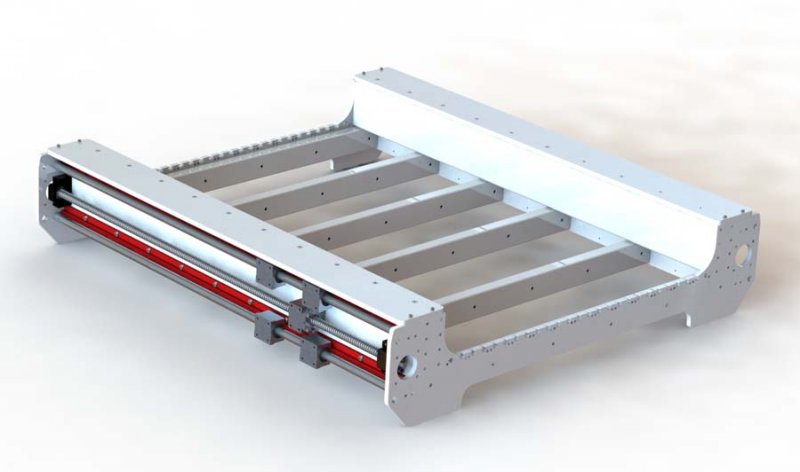

Now bolt on the top plates to prevent chips & dust into the ball screws.

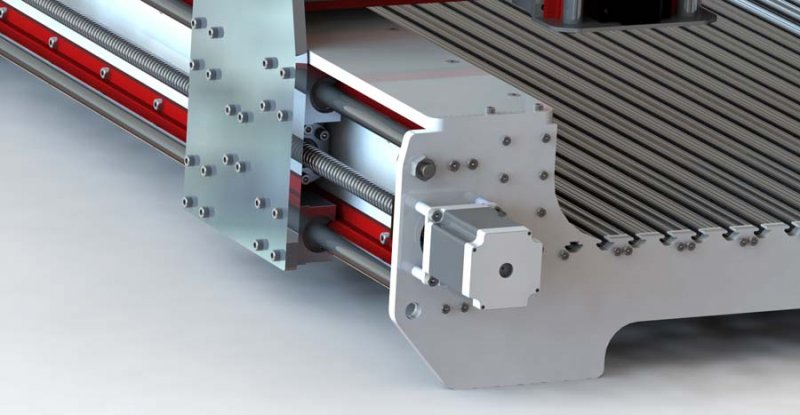

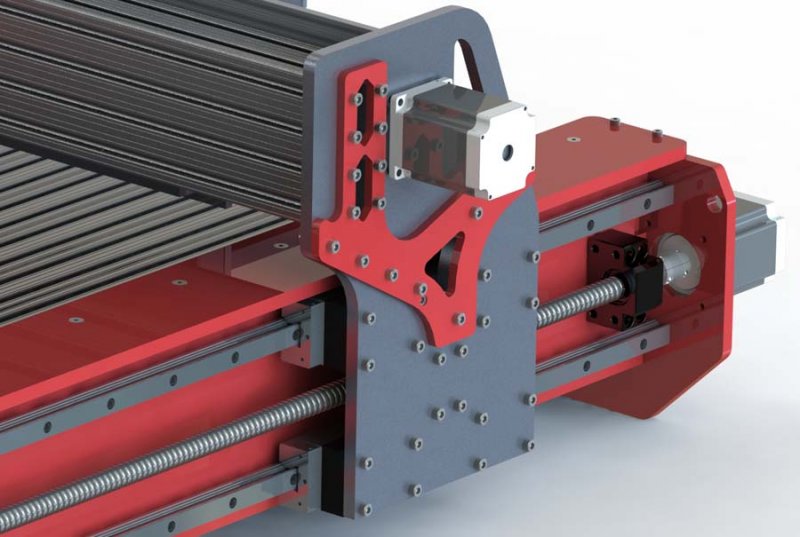

Above shows the Y axis detail.

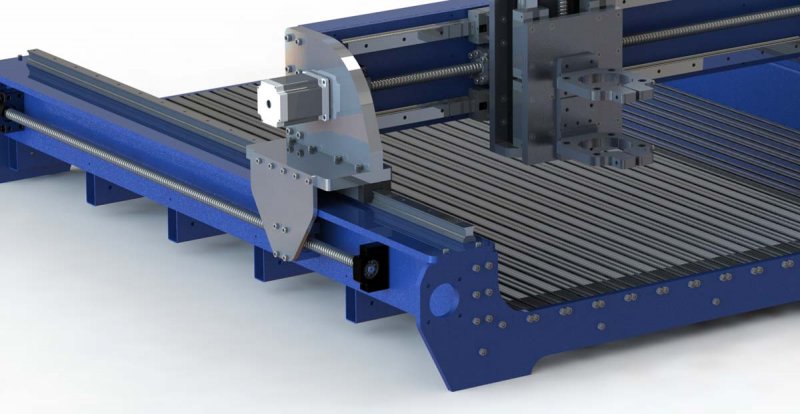

In the local classified really good deal came up on Bosch Rexroth linear bearings & hardened steel rails. So this has caused a major redesign and rethink in what I'm building!

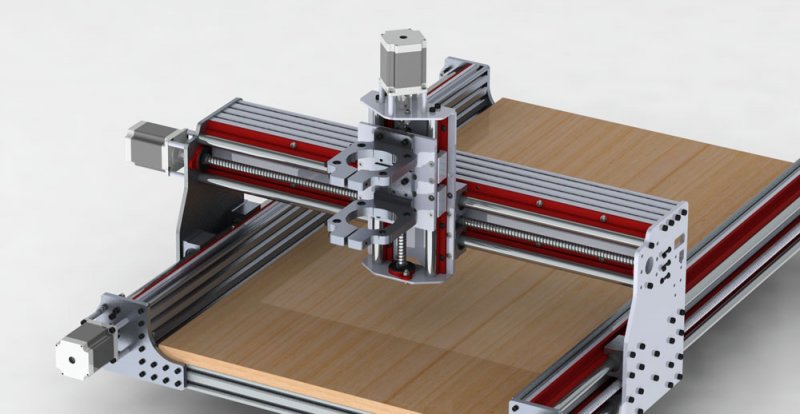

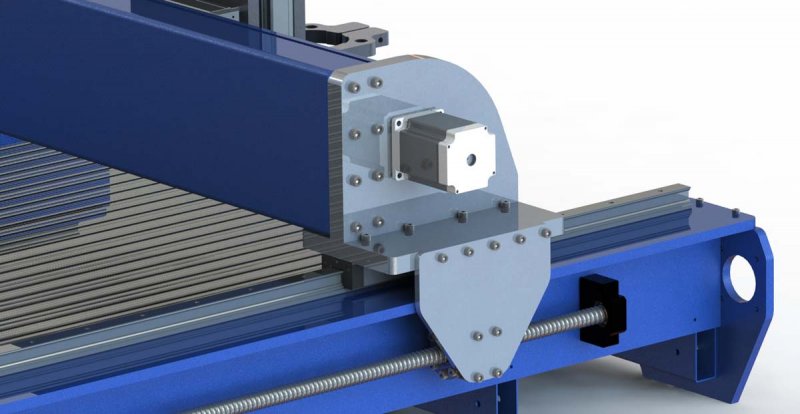

I noticed that the spindle/router is too far forward with the standard style OX style plates. After browsing through lots of CNC designs, I decided to mount the beam further back and re-design the plates.

Also decided to make the gantry plates from 1/4" aluminium and add some mild steel reinforcements to distribute the loads because I don't want to make the overall plates any thicker.

Well just a little progress, I'm still in the waiting for parts to arrive phase!

I collected the Bosch linear bearings last week. Awesome quality, really heavy duty and much more suited to a machine that can cut metal.

I made the final decision and sent for all the antibacklash ball screws.

22 April

Antibacklash ball screws arrived today and I'm very, very pleased with the quality.

25th April

Major redesign today to improve structure and make it stronger.

Next create and accurate metal cutting list and have the steel tube cut to size.

I picked up new CO2 bottle.. So almost ready for welding phase.

Current Parts List for the steel frame CNC work in progress

I thought I would share the costs involved with this design, as you will notice it's a major investment above building the regular OX build! I will add prices as the project moves forward.

Leadscrews from Ebay

Two RM1605 antibacklash balls screws with nut, RM1605, 1000mm long

One RM1605 antibacklash balls screws with nut, RM1605, 850mm long

One RM1605 antibacklash balls screws with nut, RM1605, 300mm long

4 sets BK/BF 12 bearings

Four nut holders DSG 16H

5 Couplings 1/4" to 16mm

Cost for lead screws $451

Aluminium Extrusion 80/20

One 2040, 4" by 2" by 35" long

Fifteen 2012, 2" by 1/2" by 46" long

Mild Steel Tube

Two 4" by 2" by 46" by 1/8" wall thickness

Six 2" by 1" by 30.5" by 1/8" wall thickness

Mild Steel

Two gantry stiffening plates 1/4" thick

Two end plates 3/8" thick

Two Y axis top plates 3/8" thick

Linear Bearings

Sixteen Bosch Roxroth R165329423

Linear Rails (20mm by 20mm hardened ground steel)

Four at 44"

Two at 34"

Two at 12"

Cost for Rails & bearings $454

X Gantry

Two 3/8" aluminium plates

Z Carriage

One 1/4" rear mounting plate

One 1/4" top plate

One 1/2" bottom plate

One 1/4" mounting plate

Linear Rail CNC Machines

Build in 'CNC ROUTER BUILDS' published by sgspenceley, Apr 25, 2015.

A CNC build using linear rails & lead screws.

-

-

-

- Build Progress:

-

- Build in Progress...

Attached Files:

-

Special Notes

A special thank you to Mark for sharing his original OX design and getting me started on the CNC adventure.

You, drjavad, Jochen Maier and 93 others like this. -

-

Build Author sgspenceley, Find all builds by sgspenceley

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution NonCommercial - Share Alike - CC BY NC SA

Reason for this Build

For machine sim racing parts.Inspired by

Geralds Strong Ox & Neils Frog design