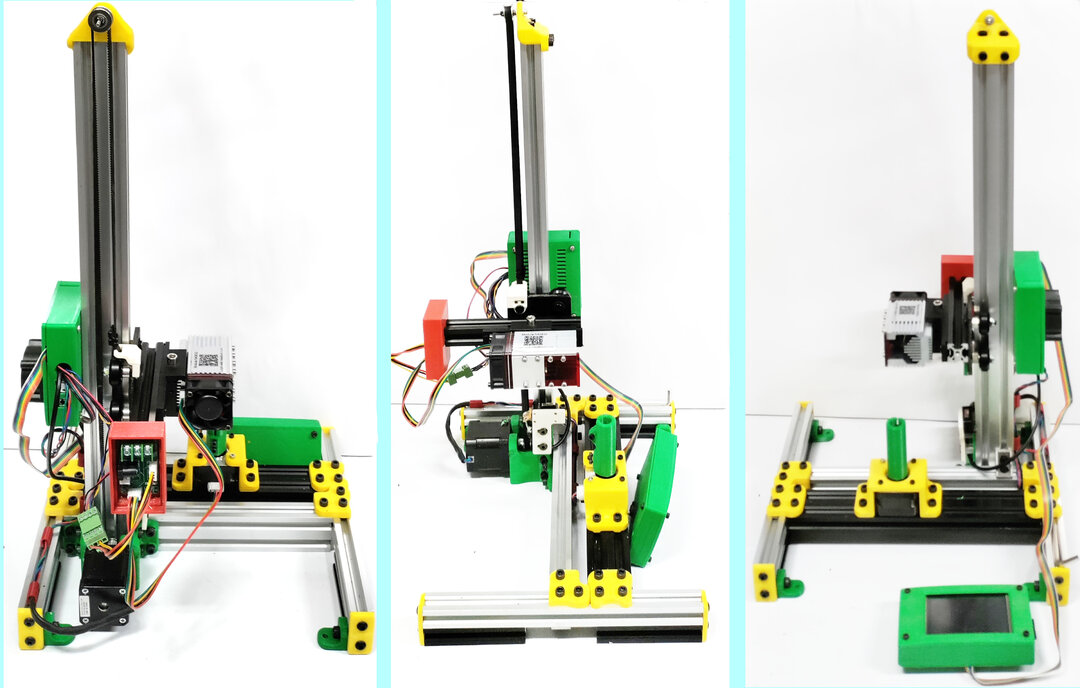

I saw David Bunch’s awesome Dedicated Compact Rotary Axis Laser Engraver (aka pen/toothpick laser) and I felt I needed one. I also figured I could expand its rotary size by making a mini-Longworth chuck. I will not include a parts list, because this is truly a scrap build. I had lots of 2020 and 2040 scraps, scraps of HDPE sheet (Black Starboard), scrap ABS sheet, and small amounts of left over rolls of green and yellow ABS filament.

The majority of the build was just printing out David’s files and attaching where necessary. His files can be found here: Dedicated Compact Rotary Axis Laser Engraver by GeoDave. I used pulleys and M3 hardware I have leftover from a K40 modification using Openbuilds parts I am in the middle of right now. The belts are leftover from an Acro build I started several years ago and never completed due to a laser diode issue and then I got distracted by my LEAD Lathe and other machine modifications. Eventually it will get done,,,but then I will need new Nema17 steppers because that is where one of these came from. The other was a pancake stepper I got from Amazon so it would fit the 3D printed parts.

To join my scrap 2020 pieces lengthwise I used 3D printed V slot joiners: V-Slot connector

I used those everywhere I needed 2040 and was using two 2020 pieces.

I did mill the belt fastening plate out f scrap ABS plastic sheet because it was quicker and stronger than printing.

I used Laser GRBL for my first tests, but I decided to get Lightburn V1.2 from the OpenBuilds Parts Store, because I do a lot of rastering with my CO2 laser and part of its update will be to convert it over to GRBL for Lightburn use. It also made these pen laser drawings easy.

Pictures of the colorful finished product:

I tested it out with a Mythosaur engraving.

After doing several pens for gag gifts, I realized this could be used for engraving mugs and water bottles so I found a Longworth Chuck drawing online and copied it for 3 mm hardware using Fusion 360. I also modified one of David's files (DrillChuck_1_4InchSpindle_M5) to be used as the chuck mount. I drew up the pegs for gripping and put small O-rings on them for grasping. Hand tightened, it grips very strongly.

Assembled:

32oz Hydroflask

I have not yet got around to testing the chuck. Hopefully that will be done soon.

Dedicated Rotary Laser Made from Scrap and Spares

Build in 'Laser Cutter Builds' published by Giarc, Sep 17, 2022.

A clone of https://openbuilds.com/builds/dedicated-compact-rotary-axis-laser-engraver.10204/

-

-

-

- Build Progress:

-

- Build in Progress...

Petertn, Ariel Yahni, David Bunch and 2 others like this. -

-

Build Author Giarc, Find all builds by Giarc

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution - CC BY

Reason for this Build

I really liked David's build and realized I had enough leftover bits and pieces to build one.Inspired by

-

Attached Files:

-