Hi, Folks!

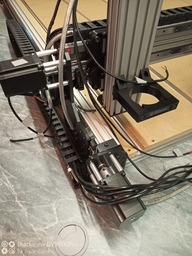

After 9 weeks of waiting i finally got my new killerbee 1515 from RatRig.

I chose this CNC because it seemed to me to be the best in terms of stability.

The stability can be guessed at just by the weight that the parcel carrier had to carry.

Of course I immediately started assembling it.

I took my time, because a precise assembly would definitely be worthwhile.

I donated a sheet steel housing from rittal for the electrical construction.

It houses the 24V power pack, the xpro-v5 controller and some relays for switching the loads.

Apart from the 230v line for the router, all lines were brought out on plugs:

- the stepper motors x/y/y2/z

- the limit switches x/y/z (there are 2 for each axis)

- the led lighting of the router

- the emergency switch

- the probe

- a cable for a laser module (later ?)

To be continued ...

--------------------------------------------------------------------------------------------------------------------------------

OK, here is an update... it took almost a year to pimp my CNC

There was still a lot of work to be done:

- The router-collet was unusable - that means: new motor...

- A t-slot table was built, but was not strong enough...

- The search for the right software was sobering...

But one after anonther:

Motor:

I bought a 2.2 kW spindle with ER20-collet and use it with a VFD.

The advantage of the ER20 collet is that i can use cutters up to 12mm.

The spindle is a 80 mm air-cooled motor from vevor.

The VFD is a cheap version with RS-485 Interface, but it was unable to use this Interface.

After some trial and error i now use the 0-10v interface, which works reasonably well.

The motor-start-up was a bit bumpy, but after using the autotune function, the motor was

easy to use. Unfortunately i had an EMI problem: every time i started the engine there was

an error with the limit switches! When troubleshooting, i found that the limit switches have

no terminating resistor in the idle position. The solution: a 47k resistor on the limit switch supply terminals.

T-nut-table:

I bought aluminum c-profiles which i mounted between strips of MDF-wood.

When clamped, however, the profiles bent.

The solution: a fold (in German: Falz) underneath the MDF wood that partially covers the c-profile.

Here the photos...

Before:

After:

Software:

That was the biggest challenge of the last few months...

A few more details on this later.

In short: I was able to work and generate G-code with Carbide Create V6 without any problems.

As of v7, G-code generation is no longer possible.

To be continued ...

--------------------------------------------------------------------------------------------------------------------------------

Update -- February 26, 2023

Here is a Picture of my actual Project - some custom-sized Cabinets for my Son's kitchen...

Herefor I use Cabineo 8 (one-piece cabinet connector):

Please stand by for more Information.

-------------------------------------------------------------------------------------------------------------------------------------

KillerBee 1515 customized

Build in 'CNC ROUTER BUILDS' published by StephanG., Feb 26, 2023.

Killerbee 1515 with modifications.

-

-

-

- Build Progress:

-

- Build in Progress...

berniege, fxdfxd, Rebekah Anderson and 2 others like this. -

-

Build Author StephanG., Find all builds by StephanG.

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution - CC BY