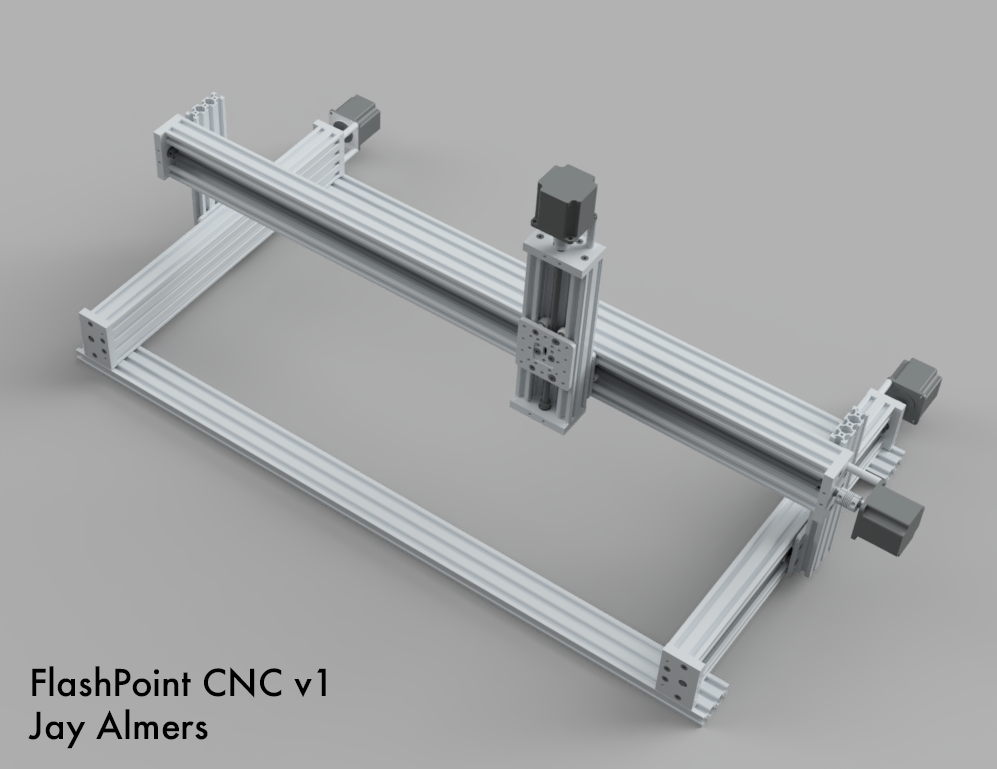

The FlashPoint CNC v1 is designed to fit nicely on the Husky mobile tool cabinet. It uses 4 NEMA23 motors with an Arduino-based board and GRBL shield. The footprint is roughly 500mm x 1000mm with a 250mm tall gantry.

Assembly is pretty straightforward; build out the C-Beam actuators, attach uprights for the gantry and brace at the bottom. The drawing above had the X-axis sitting in front of the uprights, in favor of more attachment points (4 per side, rather than two). The problem with this idea is that it places the cutter too far forward which messes with the machine's center of gravity. I went ahead and installed the X-axis behind the uprights and am far more comfortable with the balance of things. I also decided to eliminate some extra weight by flipping the Z-axis so that the carriage is mounted with 4 bolts and nuts directly to the carriage of the X-Axis.

In the Discussions section of the build, it was mentioned that the regular-sized C-Beam carts would not provide enough rigidity and could allow the cutter to twist during operation. I believe for v2 of this machine, I will upgrade to the XL C-Bean carts or build my own (See diagram in the Files section of this build). I am sure I will need to closely monitor my speeds and feeds to minimize the forces on my cutter.

I bought and installed a Dewalt DWP611 router as my cutter. It's pretty heavy but I personally thought it was more substantial than the Bosch Colt. Plus the 7 Amp, 1-1/4 HP. motor (vs. the 5.6 Amp, 1 HP motor in the Colt) made for an easy sell.

FlashPoint CNC v1: 500mm x 1000mm 3-Axis CNC Router

Build in 'Cartesian Style CNC' published by Jay Almers, Jan 13, 2019.

My build is based on many different builds but pieced together into a unit specifically to suit my needs. The footprint, without motors, is around 500mm x 1000mm with a gantry height of around 250mm. I used a combination of C-Beam, for the linear transmission, and V-Slot for the base and gantry supports. Forged angle connectors were used for attachment and I utilized the C-Beam gantry cart kits with anti-backlash blocks for both Y axes, the X axis, and Z axis.

-

-

-

- Build Progress:

-

- Build in Progress...

-

Special Notes

Built to fit nicely on a Husky mobile work cabinet:

Husky 46 in. W x 24.5 in. D 9-Drawer Mobile Workbench with Solid Wood Top in Black-H46MWC9XD - The Home Depot

DuncanF, ULADZIMIR, Mark Carew and 1 other person like this. -

-

Build Author Jay Almers, Find all builds by Jay Almers

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution - CC BY

Reason for this Build

We were in need of a platform to prototype parts and accessories to adapt commercially available RC products so they are more accessible for those with disabilities.Inspired by

Ox, Sphinx, WorkerBee -

Parts list

Qty Part Name Part Link Comments 2 1000mm V-Slot® 20x60 Linear Rail Link 2 250mm V-Slot® 20x60 Linear Rail Link 4 C-Beam Gantry Set Link With Anti-backlash nut 1 Router/Spindle Mount Link 1 1000mm C-Beam® Linear Rail Link 2 500mm C-Beam® Linear Rail Link 1 250mm C-Beam® Linear Rail Link 8 C-Beam® End Mount Link 1 1040mm 8mm Metric Acme Lead Screw Link 1 290mm 8mm Metric Acme Lead Screw Link 2 540mm 8mm Metric Acme Lead Screw Link 8 Ball Bearing 688Z 8x16x5 Link 4 Micro Limit Switch Link 4 Micro Limit Switch Plate Link 8 Lock Collar Link 4 1/4" * 8mm Flexible Coupling Link 26 Black Angle Corner Connector Link 8 Precision Shim - 10x5x1mm Link 0 Link 0 Link -

Attached Files:

-