Build List

-

Active Filters:

nema

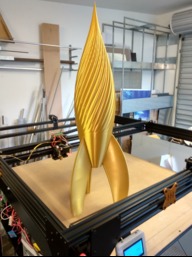

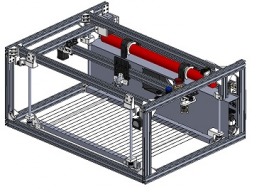

Large 'Double H-Bot' using Openbuilds 2040 v-slot

The aim of this design is to build a simple, cost effective (under $1000) and relatively compact large volume (m3) 3D printer that will use a pellet extruder to create art/design objects using shredded recycled plastics.

Build Author

Mark Carew

Views

19985

Build Author

Mark Carew

Views

19985

V-Slot™ Nema 23 Linear Actuator (Belt Driven)

This example build shows how easy it is to make a linear actuator using a few OpenBuilds Parts.

Build Author

Mark Carew

Views

58419

Build Author

Mark Carew

Views

58419

V-Slot NEMA 23 Linear Actuator (Lead Screw)

Learn to build a super strong nema 23 lead driven linear actuator

Build Author

Mark Carew

Views

14028

Build Author

Mark Carew

Views

14028

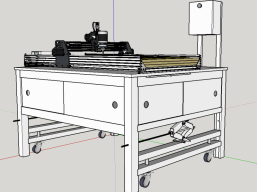

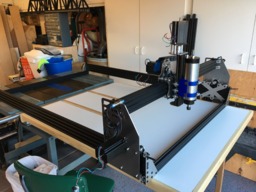

C-Beam XLarge X/Y Table

This OpenBuilds C-Beam XLarge X/Y Table is a great display of how easy it is to modify and create awesome configurations with the OpenBuilds system!

Build Author

BeTrue3D

Views

20349

Build Author

BeTrue3D

Views

20349

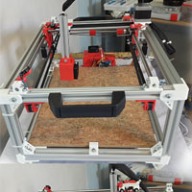

BeTrue3D Printer

High Quality CoreXY with focus on quality and optimized printarea versus physical size of the printer.

Build Author

sgspenceley

Views

186380

Build Author

sgspenceley

Views

186380

Linear Rail CNC Machines

A CNC build using linear rails & lead screws.

Build Author

Martin.Barfoed

Views

5248

Build Author

Martin.Barfoed

Views

5248

40x40 V-Slot Rod Type Linear Actuator

A Rod-type Linear Actuator based on the 40x40 V-slot profile

CubeFoot CNC

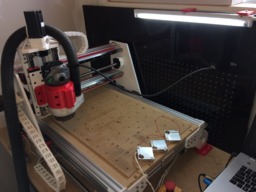

This small desktop machine is built inside a 300mm cube of 20mm extrusion. Work area is 14cm by 14cm. I used 400 step nema17 motors all around.

Build Author

nickchnv

Views

10367

Build Author

nickchnv

Views

10367

Rigid Compact Desktop C-BEAM

This modified C-Beam, is a compact, powerful and affordable desktop CNC.

Fastmill CNC

Very cheap CNC made from laser fired and bent parts.

Build Author

Mark Carew

Views

12842

Build Author

Mark Carew

Views

12842

NEMA 17 Belt and Pinion Actuator

This Belt and Pinion actuator is a great example of how easy it is to convert your machine into a belt drive system.

Build Author

Rob Taylor

Views

9102

Build Author

Rob Taylor

Views

9102

Grizzly G0758 Benchtop Mill Conversion

A proper CNC mill conversion. But quite small, with my trademark idiosyncracies.

Build Author

Mark Carew

Views

14717

Build Author

Mark Carew

Views

14717

Nema 23 Belt and Pinion Actuator

This easy to build and effective system can take your builds to the next level! This design is strong and accurate and could be the solution/upgrade that you've been looking for!

Build Author

Kenneth Witthuhn

Views

7439

Build Author

Kenneth Witthuhn

Views

7439

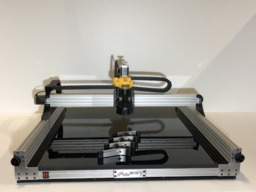

Openbuilds CNC (witthuhnCNC XKLBR-1S)

Based on the popular C-beam / V-wheel design, with the largest available work area, relative to machine size. Screw driven with anti-backlash, integrated drag chains, Carbon fibre gantry plates, Openbuilds BlackBox Controller (USB), Transformer & kill switches, with internal wiring, limit switches & Nema 23 motors.

Build Author

Forestbird Originals

Views

3992

Build Author

Forestbird Originals

Views

3992

Lead 1010 Build - Anything but stock.

This is a lead 1010 build that I wanted to have a little fun with. I purchased the whole Lead 1010 kit, and felt like studying a few shortcomings of the original to see if I can improve it or just have some fun with it.

Build Author

HuguesP

Views

8262

Build Author

HuguesP

Views

8262

YACLR CNC

Yet Another Chinese Linear Rail CNC, my first one, doing this mainly for the fun of building it more than using it.

Build Author

Fábio Pires

Views

6081

Build Author

Fábio Pires

Views

6081

Frezar - Desktop CNC

This is a small desktop CNC inspired by the Mini OX project. It's designed with the nema 17 motors in mind. It's a 650mm x 500mm machine that it will be used to mill cast acrlic.

Build Author

taratata2016

Views

7004

Build Author

taratata2016

Views

7004

Panther 3D printer

After use of the i3 Prusa 200x200x180, the volume increases to 300x300x450 on the V-Slot and driven by a Megatronics V3

Build Author

Lasersc

Views

9499

Build Author

Lasersc

Views

9499

D&R Tiger Paw build combo

The Tiger Paw will be a 1000mm X 500mm Cartesian style CNC with the Minimill attached to the end. It is named the D&R Tiger Paw because my son, Daniel, and myself, Richard, will put this Tiger strong and fast machine together. Our goal is to have a Tiger strong build with a Paw print that wouldn’t take up a huge amount of space in our garage.

Build Author

viktop

Views

16152

Build Author

viktop

Views

16152

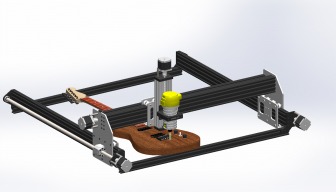

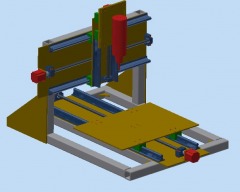

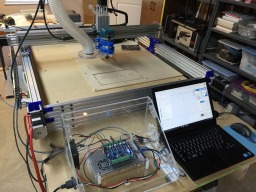

Simple CNC Router (Nema17, V-slot 2040, Arduino, GRBL)

An OX-inspired mini desktop mill.

Build Author

roadss

Views

23192

Build Author

roadss

Views

23192

Rawcnc 1.5 Desktop Edition

This will showcase the build of my Rawcnc 1.5. A rigid cnc router from the Swedish company Rawcnc, featuring a rather cool linear motion system, rack & pinion and steel reinforced X-axis capable of milling aluminum.

Build Author

KronBjorn

Views

3689

Build Author

KronBjorn

Views

3689

WorkBee Lead 1010, Reduced Footprint, Nema17

This is a WorkBee 1000x1000mm with lead screws and Nema17's. It has a reduced footprint, with the geared Nema's inside the frame.

Black Rabbit 1500

This is a router that I designed that is loosely based on the Openbuilds Ox, but designed to be heavy duty, rigid, and yet quick and agile.

Build Author

Christian James

Views

7550

Build Author

Christian James

Views

7550

Workbee "style" 1010 cnc

This build is based on the Workbee 1010 CNC. It is not a kit build and is much the same as the original but with some significant changes made here and there as the build progresses.

Build Author

Lumberjack Engineering

Views

18297

Build Author

Lumberjack Engineering

Views

18297

SOLAC: Space Optimized LAser Cutter

The Space Optimized LAser Cutter is a 40 watt CO2 laser cutter that supports a maximum part volume of 24" x 16" x 6.25". It consists of a V-slot frame + brackets/mounts designed to be 3D printed on a consumer desktop printer. Total cost of the machine is ~ $1,400 USD.

Build Author

Rob Mahan

Views

11742

Build Author

Rob Mahan

Views

11742

Rob's C-Beam Machine XLarge

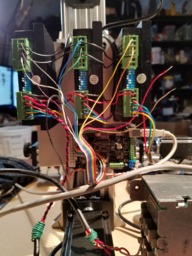

This is my first CNC router build, so I started with the OpenBuilds C-Beam Machine XLarge mechanical bundle, including four high torque stepper motors. I took my time with the mechanical build, sought and found some great help for my control system, and designed and built a custom cabinet to house everything.

Build Author

MikieLikesIt

Views

7529

Build Author

MikieLikesIt

Views

7529

Cousin CNC OX Router

A lower profiled machine. Built all out of aluminum. Removable control panel/PC unit. Option for vacuum table and cooling pump for a spindle.

Desktop CNC

This unit is made with openbuild v-rail and c-beam. using direct drive with lead screws. Nema23 motors

Build Author

Carl Siren

Views

6499

Build Author

Carl Siren

Views

6499

CNC-machine 650by700

A home-made CNC-machine with a 1.5 kW air cooled spindle motor suitable for milling materials such as wood, plastic and soft metals. The work table is 650 mm wide by 700 mm deep and the maximum movement is set to 560 mm for the x-axis, 480 mm for the y-axis and 105 mm for the z-axis.

Build Author

Julius

Views

23800

Build Author

Julius

Views

23800

OX Balls - 1605 Ballscrew Powered 1000mmx1000mmm OX derivative

1000x1000mm Ballscrew driven OX Derivative. Dewalt 611 spindle and TB6600 Drivers.

Build Author

pedrofernandez

Views

6719

Build Author

pedrofernandez

Views

6719

ACRO 20x20

The Acro Laser Machine Build

Build Author

Tommy Williamson

Views

5616

Build Author

Tommy Williamson

Views

5616

Motion control camera slider based on the V-Slot® NEMA 17 Linear Actuator Bundle (Belt Driven)

I built a motion control camera slider with the V-Slot® NEMA 17 Linear Actuator Bundle (Belt Driven)

Build Author

Limine3D

Views

3473

Build Author

Limine3D

Views

3473

Shapeoko 1 upgrades

Replaced the original Z-axis for a shapeoko with a c-beam upgrade. This upgrade required a nema 17 mount and a quiet spindle mount I printed with a 3D printer.

Build Author

hbtousa

Views

2399

Build Author

hbtousa

Views

2399

Quack Ball

Quack Ball is a game in which the objective is to knock down moving ducks. The ducks are protected by a barricade that moves at a very fast speed. The game can be played individually or by two or more players. Each round consists of a total of ten targets to shoot and each player will have four balls to shoot. Prior to beginning play, a player selects how many ducks, maximum four, the player will knock down continuously. If player fails games is over for that player.

Build Author

jz321

Views

3649

Build Author

jz321

Views

3649

OTiS 500mm

OTiS (Off The Shelf) is 500mm cartesian CNC that can be built with all off the shelf parts from OpenBuildsStore. It features C-Beam actuators and a V-Slot frame.

Bedroom Builds (BrB) DIY CNC

So I am employed in the automotive industry and I walk by thousands of dollars of CNC products daily that are no use to me due to being a Technologist and not a machinist. So therefore with some research I found openbuilds and their great selection of products to build my own CNC. This CNC will consist of 4 axis one removable 360 degree axis for turning alongside a x axis table Y axis stationary gantry and a Z axis attracted to the Y axis linear actuator.

Build Author

Rob Withoff

Views

3881

Build Author

Rob Withoff

Views

3881

Mini-Mill Enhanced

Some enhancements of the basic mini-mill

Build Author

Huub65

Views

7577

Build Author

Huub65

Views

7577

My C Beam - NEMA 17 - GRBL- Arduino project

Cbeam machine. Using small stepper motors (NEMA 17) and Arduino controller. Try to get this working in de upcoming month.

Build Author

Ronald van Arkel

Views

15397

Build Author

Ronald van Arkel

Views

15397

Upgrading the C-Beam machine

So we have new plates, stronger motors, belt drive reduction, but what should we do with them? In this article you might find the answer you were looking for as we took an “old” C-Beam machine and started to upgrade the X/Z body and added more torque and precision to the Z-axis.

Build Author

Tucstrlly

Views

7840

Build Author

Tucstrlly

Views

7840

Stainless OX Kit Build "Diamondback CNC"

A copy of the Stainless Ox by Martin Barfoed. Similar design, construction and control.

Build Author

ZacharyB

Views

4618

Build Author

ZacharyB

Views

4618

Arizona OpenBuilds MiniMill CNC

I ordered the OpenBuilds MiniMill from the OpenBuilds Parts Store http://openbuildspartstore.com/ They were out of Motors and Electronics when I ordered so I had to source these items elsewhere. But it turned out well doing it this way.

Build Author

zelos

Views

18074

Build Author

zelos

Views

18074

ZelosLaser Engraver/Cutter 2.0 : Sturdy & Versatile

Zelos Laser Cutter Version 2.0 GRBL Shield with Nema 17 motors. 2 Watt laser for cutting and fine grayscale pictures built very sturdy and modular

Build Author

Anthony Castelluci

Views

2599

Build Author

Anthony Castelluci

Views

2599

Simple Camera Lofted Camera Slider

Build a manual camera slider.

Build Author

THE LINK

Views

4314

Build Author

THE LINK

Views

4314

2020 First build.

Probably cheapest DIY build youl see.

Build Author

M^3

Views

20621

Build Author

M^3

Views

20621

M Cubed CNC Mill

A no-nonsense CNC mini mill to get the job done.

Build Author

Hisha

Views

4108

Build Author

Hisha

Views

4108

Routy based build

Routy based build using 1000mm Y axis beams and 500mm X axis beams. Using a 20x80 Z axis to use the OpenBuilds router mount.

Build Author

Steven Sampson

Views

9958

Build Author

Steven Sampson

Views

9958

RiNo Route

A CNC router designed to handle a 4'x8' sheet, for as close to $2000 as possible. The price barrier resulted in my choice to use timing belts rather than leadscrews or rack&pinion. Build List still being updated

Build Author

Matt Barile

Views

6260

Build Author

Matt Barile

Views

6260

Fixed Gantry Welded Steel Router

Fully welded, fixed gantry CNC router, with chinese linear motion parts, in progress

Build Author

3D Meister

Views

4217

Build Author

3D Meister

Views

4217

Camera slider with rotation prototype

I made a cam slider prototype with adjustable rotation to get experience for my CNC milled slider in planing.

Build Author

Keteland

Views

9894

Build Author

Keteland

Views

9894

MULIMATERIAL 3D PRINTER (in progress)

ELECTRONICS - ARDUINO Mega 2560 + RAMPS 1.4 + power supply 12V - Leadshine DM 5042 external driver + Power supply 36V + NEMA 23 stepper motor SOFTWARE - Repetier Host to communicate with the Ramps - ARDUINO to upload the firmware (Marlin) MECANIC - V-Slots rails 40x40 + home-made plates - everything goes fine on the side of the build

SUPER OX NEMA 34 1600 OZ Motors!!!

CNC OX 1500X3000

Build Author

Bridge Port

Views

7827

Build Author

Bridge Port

Views

7827

CNC Line Boring Machine

This is a CNC Line Boring Machine for our cabinet shop. It drills the holes every 32 mm for the adjustable shelf pins in the cabinet side pieces. I chose this option over purchasing a multi-head boring machine that requires 11 drill bits - Left & Right hand twist - that also requires a lot of strength to plunge that many drill bits into the wood to be drilled.

C-Beam Big Mouth

My first build was with the basic C-Beam Build. I soon found the z clearance a little constricting So I added 2 500 mm actuators to support the x axis rail . I also left off the front and back y axis support rails for easy cleaning. I mounted the base of the machine to 1/2" mdf with 10/32 screws and blind nuts.

Build Author

Rwetzler

Views

8131

Build Author

Rwetzler

Views

8131

C-Beam Prototype

This is a variant of a typical OX (Mark Carew inspiration) router using C-Beams/8mm Acme rods to drive all three axis. I went with a 1000mm x 1000mm frame size. Useable space is 28" (711mm) X 26" (660mm) with a Z axis work travel of approx. 3.25" (82.5mm). A TinyG is used as a controller along with Fusion 360/Chilipper as the software for generating and running gcode files.

Build Author

Sheepdog

Views

25415

Build Author

Sheepdog

Views

25415

Griffin Delta Printer

Designed from the ground up as a low cost, highly scalable delta printer. This printer has been built as small as carry on luggage size, up to an 18in wide print surface and is capable of larger. Approximate cost is low to mid $500 range start to finish, including electronics for a basic model.

Build Author

Gary Bonard

Views

5285

Build Author

Gary Bonard

Views

5285

OxZilla

This is my second Ox with a working area of 14" x 14" x 5" I wanted to build a small sturdy potable CNC router and this OxZilla has the nice upgrades !

My Little OX

This build has been an educational experience. Software and hardware alike.