Spec:

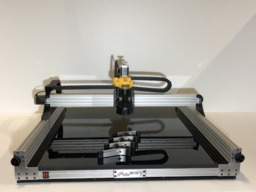

- Machine size: (1110mm x 1110mm @ 485mm high)

- Work area parameters (X: 813mm Y: 813mm Z: 90mm) - 105mm Z-travel

- Carbon fibre gantry plates (5mm depth)

- Structure (4080 C-Beam V-Slot Extrusion)

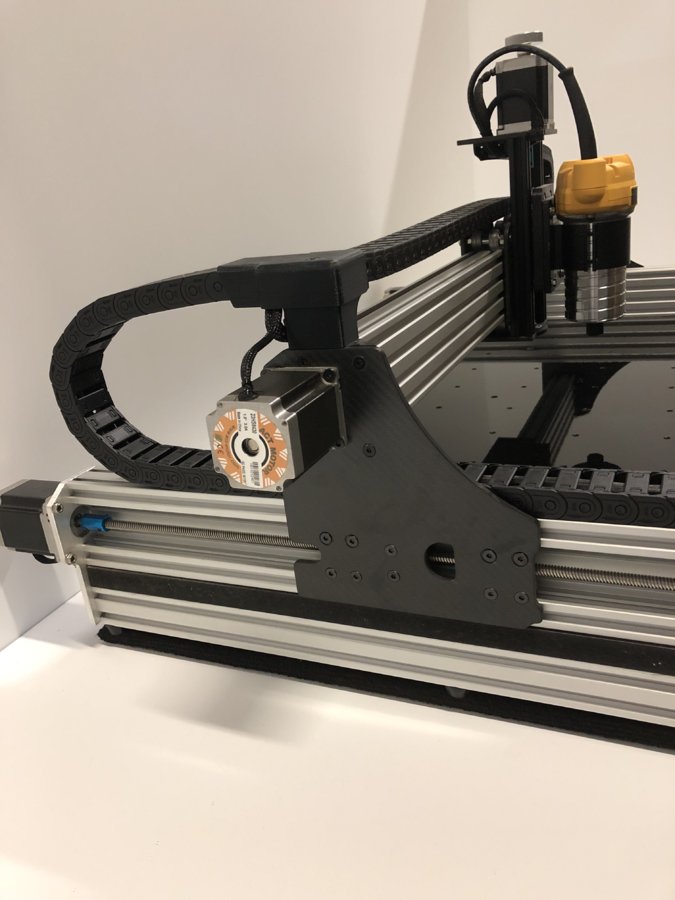

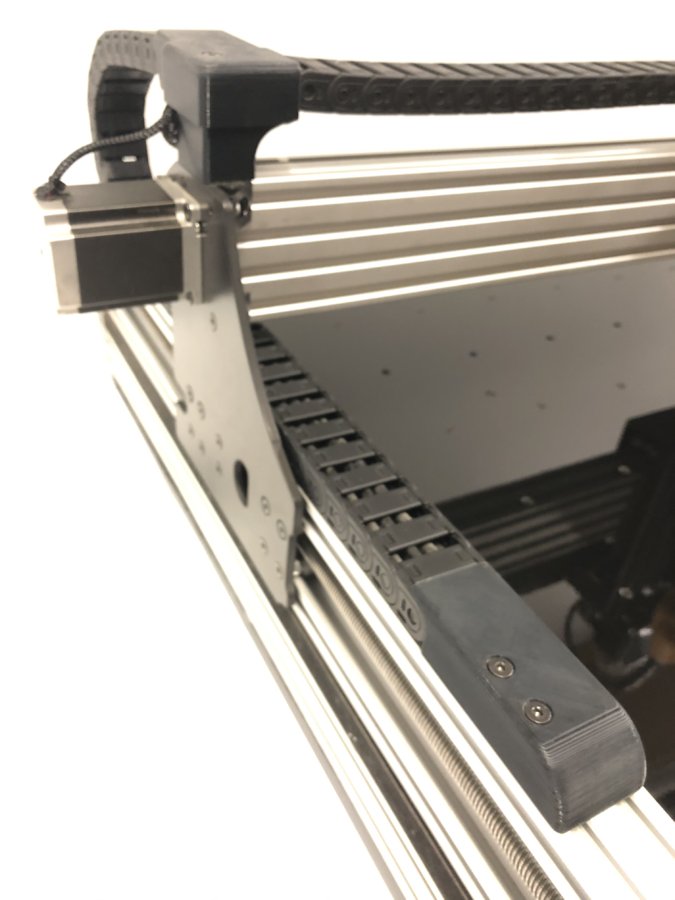

- Screw driven, Stainless steel, with ant-backlash (T8 x 8 Trapezoidal Lead Screw)

- Nema23 motors (3A 270oz / inch)

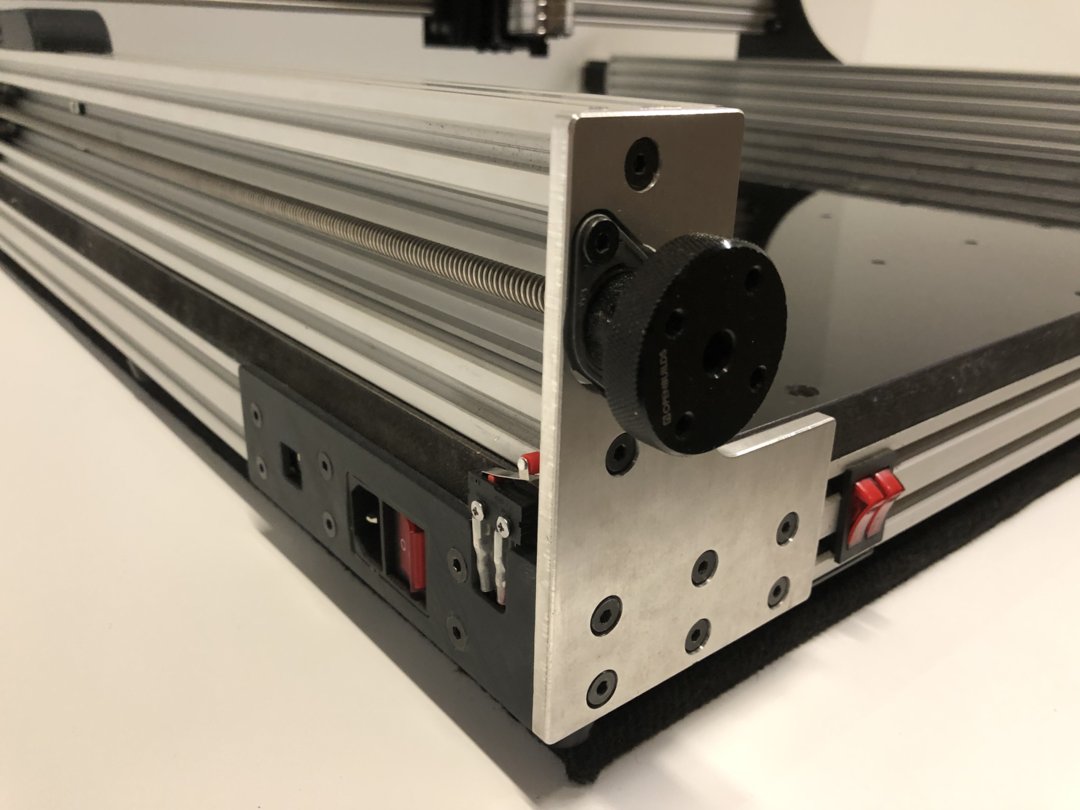

- Hand wheels on X Y Z Axis (for fine tuning & calibration)

- Xtreme V-wheels (Polycarbonate)

- Dewalt D26200 router (240V)

- Router mount (71mm Diameter)

- Dust shoe (3D Printed, with 45mm bristles)

- Openbuilds BlackBox Controller (24V), USB interface (4 x 3.2A Stepper Drivers - Max @ 4A)

- Transformer (300W - 12.5A @ 24V)

- Kill switches (Turns off Router & Pauses G-Code)

- Base (19.5mm MDF Black gloss laminate top, on 2040 V-Slot Extrusion)

- 4 x Hold down clamps (160mm Aluminium) & hand screws (M5 80mm)

- Noise dampening (Base mounted Polyurethane feet)

- Wiring (4core / 20AWG) & (2core / 20AWG)

Openbuilds CNC (witthuhnCNC XKLBR-1S)

Build in 'Cartesian Style CNC' published by Kenneth Witthuhn, Feb 25, 2020.

Based on the popular C-beam / V-wheel design, with the largest available work area, relative to machine size. Screw driven with anti-backlash, integrated drag chains, Carbon fibre gantry plates, Openbuilds BlackBox Controller (USB), Transformer & kill switches, with internal wiring, limit switches & Nema 23 motors.

-

-

-

- Build Progress:

-

- Build Complete!

-

Special Notes

Design ethos:

Machine to be as small as viably possible, relevant to the work area requirements.

Only the highest available quality products used.

Machine is to be ergonomic & tidy.

Wiring & Electronics to be contained within the machine’s extremities.

Easy to use, with integrated protection systems.

Cynic, Thomas McGravie, phuture3d and 5 others like this. -

-

Build Author Kenneth Witthuhn, Find all builds by Kenneth Witthuhn

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution NonCommercial - CC BY NC

Reason for this Build

I started with the X-carve, I didn't like the like the rigidity of it, so I used it to make some ganarty plates for the first C-beam style CNC machine. I looked @ other designs & noticed that many were big & bulky, so I tried to make my own CNC machine as compact as possible, relevant to the required work area.