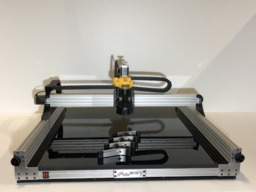

Openbuilds CNC (witthuhnCNC XKLBR-1S)

Discussion in 'CNC Mills/Routers' started by Kenneth Witthuhn, Feb 25, 2020.

Openbuilds CNC (witthuhnCNC XKLBR-1S)

Discussion in 'CNC Mills/Routers' started by Kenneth Witthuhn, Feb 25, 2020.

Based on the popular C-beam / V-wheel design, with the largest available work area, relative to machine size. Screw driven with anti-backlash, integrated drag chains, Carbon fibre gantry plates, Openbuilds BlackBox Controller (USB), Transformer & kill switches, with internal wiring, limit switches & Nema 23 motors.