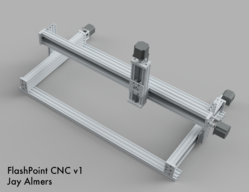

FlashPoint CNC v1: 500mm x 1000mm 3-Axis CNC Router

Discussion in 'CNC Mills/Routers' started by Jay Almers, Jan 10, 2019.

FlashPoint CNC v1: 500mm x 1000mm 3-Axis CNC Router

Discussion in 'CNC Mills/Routers' started by Jay Almers, Jan 10, 2019.

My build is based on many different builds but pieced together into a unit specifically to suit my needs. The footprint, without motors, is around 500mm x 1000mm with a gantry height of around 250mm. I used a combination of C-Beam, for the linear transmission, and V-Slot for the base and gantry supports. Forged angle connectors were used for attachment and I utilized the C-Beam gantry cart kits with anti-backlash blocks for both Y axes, the X axis, and Z axis.