This is my first attempt at a 3d printer and with not owning one already I am limited to off the shelf parts and whatever I can fab with a dremel/etc.

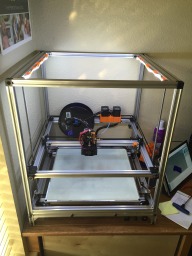

Goal was to get a 400mm cubed build space. I think I will get close, but will be a bit short. I am using mostly 500mm pieces and have a couple of 600mm pieces that were cut down from longer stock.

The whole build will eventually be enclosed in acrylic, possibly to create a heated build chamber, but more to keep little hands off hot things (very curious 15 month old).

I am using an offset belt path to avoid the twisting crossover. Trying to maximize the build area by wrapping the belt around the lead screws.

I am using 4 lead screws for the Z mechanism and using a single belt to power it. Lead screws will have 40 tooth pulleys and a 20 at the motor for a 2:1 ratio. Hopefully that will be enough to lift the gantry without issues.

CoreXY W/ Fixed Build Plate & Enclosure

Build in 'H-Bot and Core XY' published by JOSH.PIERCE, Mar 2, 2016.

Building a Core XY printer with a fixed build plate from off the shelf parts.

-

-

-

- Build Progress:

-

- Build in Progress...

SlyOne, monoplaner, Calummmmm and 19 others like this. -

-

Build Author JOSH.PIERCE, Find all builds by JOSH.PIERCE

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution - CC BY

Inspired by

C-Bot & H-Bot -

Attached Files:

-