Hello all! found this site in doing research for my project.

The short story is I decided to build what I needed in place of buying the piece of equipment for my shop.

In my industry (vinyl signs and graphics) there is an expensive piece of equipment called a roller table. they look something like this:

They aid in applications to flat surfaces, and layering multiple colors of vinyl over top of each other. This being a top of the line model retails for a little over $15k. steep price for a table.

I already have 3 tables in my shop, 4'x8', made out of 4"x4" timber. my brain immediately went to creating an structural top with some linear motion and some sort of gantry system that i can place on top of one of my existing tables.

In researching linear motion solutions, I came across this website with all the goodies and an active community of member's. Plus, all the parts are on google sketchup, so I can "build" it before i actually build it. Home run.

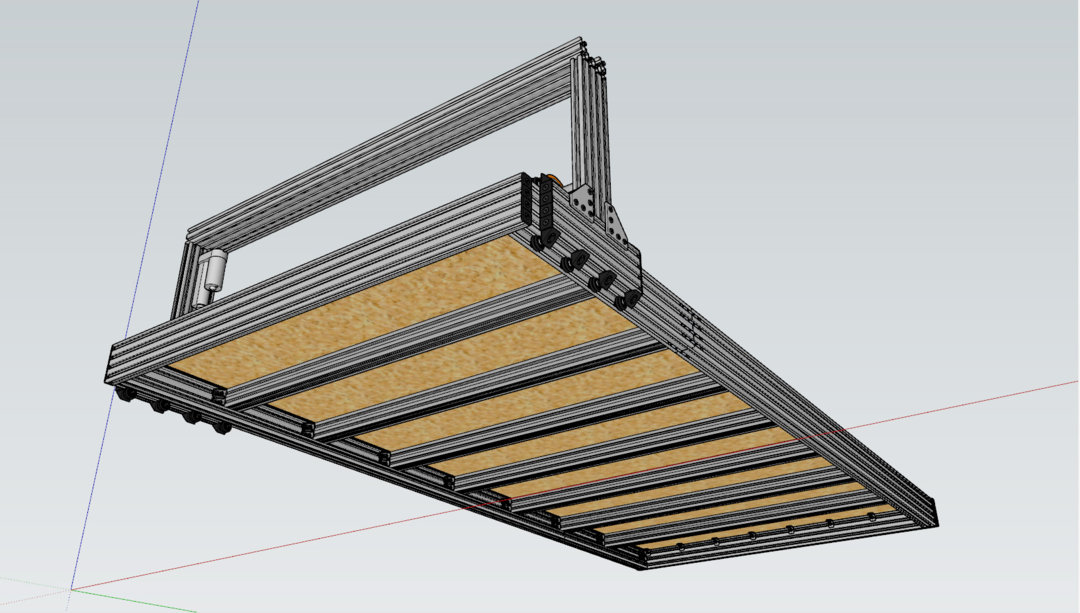

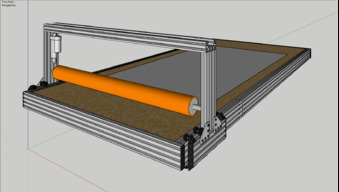

So, attached you can see the concept I have designed in sketchup.

At first, I designed this table around an existing laminator roller I already had, but after some searching, I found that I can have a custom roller made to suit my needs within my budget. So I will be adjusting the lengths for the table to basically drop over and attach to a 4'x8' table that is already in my shop. The design will remain the same.

I am basically putting this out there to see what you guys might have to say that I'm doing wrong or right.

Update 10/13:

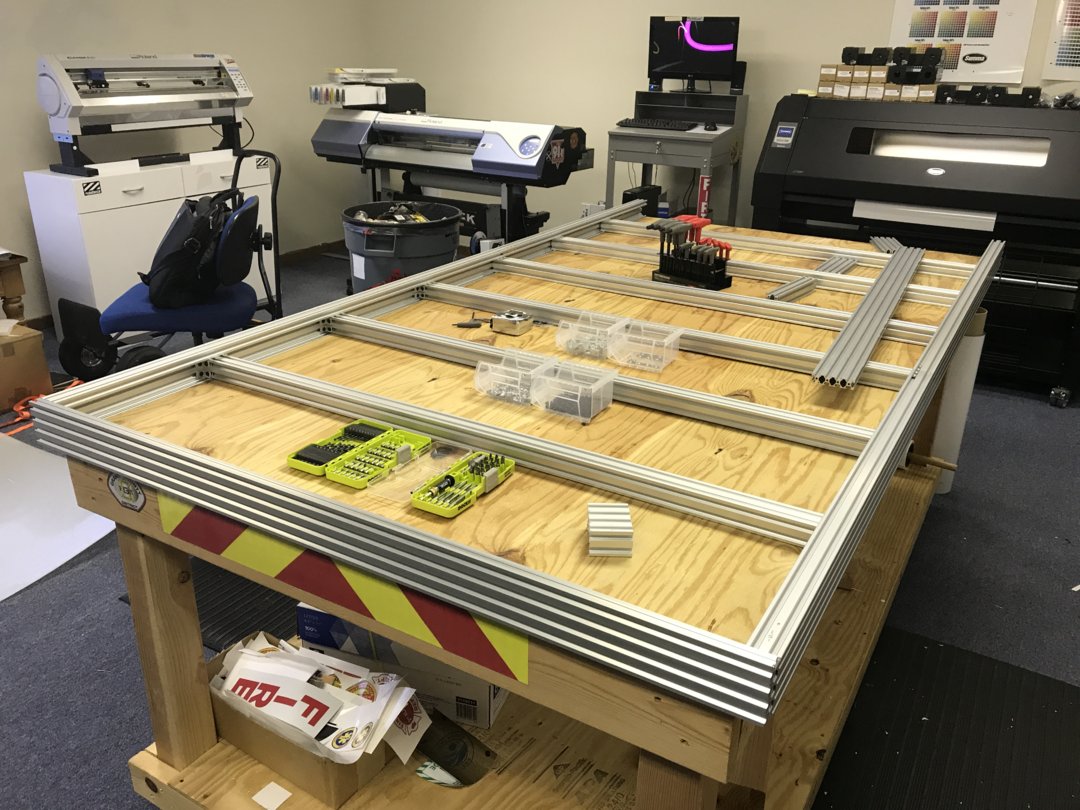

First order of parts came in. Starting with the table top first. Pretty simple table I built, no frills. Gets the job done.

Here we go! Setting up the frame, and I quickly find out that the t-handle Alen wrenches are not the easiest to work with inside the corners.

Tonight will have to be just the frame. I didn't realize that 3/4 MDF is sold in sheets 49"x97" so I have to take it home to rip an inch off two sides.

Oh well.

Vinyl Application Roller table

Build in 'Everything Else' published by Mac6986, Oct 13, 2017.

Build progress of custom roller table for applying graphics

-

-

-

- Build Progress:

-

- Build in Progress...

Arockstarslifej26, Sign money, Zeus Arts and 23 others like this. -

-

Build Author Mac6986, Find all builds by Mac6986

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution NonCommercial - CC BY NC

![[IMG]](proxy.php?image=http%3A%2F%2Fwww.arctec.co.za%2Fopencms%2Fimages%2Fproducts%2Ffinishing%2Frollsroller%2FROLLSROLLER_400-170_High_360_x_316_px.jpg&hash=52c2ac5ededcb8a5ea7538d2d031d438)