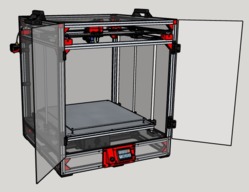

The Plastic Beast CoreXY Printer

Discussion in '3D printers' started by cdsmith12, Feb 28, 2018.

The Plastic Beast CoreXY Printer

Discussion in '3D printers' started by cdsmith12, Feb 28, 2018.

In my opinion, this is the easiest and most complete tutorial to walk you through building a large platform 3D printer and the Sketchup File is included for you to make any changes needed.. The Plastic Beast is a CoreXY Printer with a build platform of 440mm square. You can print 600mm or about 23 inches diagonal. Any level of user from novice to expert should gain something from my tutorial.

Tags: