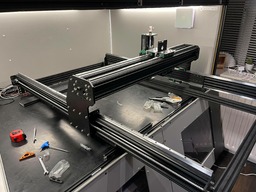

Full HGH 15mm linear rail set up, 12mm ball screws all round (T12 lead screw option) Tall Y Gantry plates, Y Axis strengthening beams and plates.

Adding 12mm lead screws or ballscrews simply takes the BlackBee to a next level, machines harder, faster and deeper with ease.

Benefits are shown below but not limited to:

1. Option of 12mm ball screw or lead screw

2. Elimination of X axis twist, vital if you are machining regularly (no upgrade other kit addresses this)

3. Better accuracy all round than comparable openbuild kits

4. Smoother drive and smoother motion with linear rails

5. Easier to build than the wheel type motion

6. Rigidity built in, on every axis there is no need to upgrade further.

7. Thicker, better lead nuts, or ball nuts

8. You can machine harder, faster and deeper with this kit

9. Production machining times are much shorter

10. Larger tool bits can be used for clearance areas

11. Keeps the original C-Beam extrusions

12. Use more of your Z gantry

13. Easier maintenance

14. No need to regularly check wheels, bearings and postion of wheels!

15. Rigidity plates bolt to the Y axis V-beams, preventing sway from side to side when machining in X direction, again no other upgrade kit addresses this issue.

16. Dedicated lead nut & ball screw mounts to enhance rigidity

Mechanical kit Consists of:

Actuator

Aluminium Extrusion 1500mm, 1000mm, or 350mm, 12mm ball screw, length to suit extrusion, machined to fit, ball nut & ball mount, Motor end plate, non motor end plate, Stepper motor spacers, thrust bearings, shims

- 3 of 15mm HGH type linear rail motion actuators 1000mm (or 1500mm), 12mm ball screws and ball screw mounts

- 1 of 15mm HGH type rail motion actuators 250mm, 12mm ball screws and ball screw mounts

- Anti-Twist Tall Y gantry plates

- Extra C-Beam for Anti-Twist, eliminates twist on the X axis completely

- Taller End plates to allow full use of 250mm Z (normal use is around 50mm travel only)

- X/Z Gantry linear motion drive

- 2 of Drag chains, X and Y, Drag chain fixing plates, Drag chain support for X axis

- Complete base frame to support spoil board (not including spoil board), with 4 of rigidity plates for Y c-beams (stops the Y c-beams moving in or out, attaches to base to enhance rigidity)

- Nema 23 motor mounts

- Corner brackets to secure all extrusions in place

- All hardware (bolts, nuts, washers etc) to assemble for all above

- Belt or Rack drive for longer than 1.5M Y axis

The BlackBee CNC

Build in 'Cartesian Style CNC' published by CNCGear, Mar 12, 2021.

Ball screw drive, linear rail CNC Kit

-

-

-

- Build Progress:

-

- Build Complete!

Attached Files:

woodstockhokie, Evangelos Mangalos, Lloydsch47 and 6 others like this. -

-

Build Author CNCGear, Find all builds by CNCGear

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution NonCommercial - No Derivs - CC BY NC ND

Reason for this Build

This was built to show that a real CNC can be made from opebuilds products.