Based on @Kyo's Sphinx and @beardyblair's XL variant.

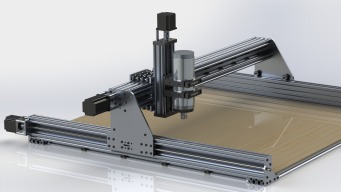

This is a 1m C-Beam build with a reinforced X Gantry to support heavier spindles & increase rigidity for aluminium milling. The build will progress in stages, the 1st stage being a replication of beardyblair's build with modified Y-Axis side plates that allow for a second C-Beam to be placed back to back.

After testing the first stage and finding where I am limited I'll start the second phase (if necessary). Adding the second aluminium profile to the gantry. All of my drawings are done in solidworks, plates will be laser cut then drilled and counter bored on a turret mill.

Control system will start out as either LinuxCNC or an arduino running GRBL, depends upon having a pc with an ancient parallel port. As I invest more I'll look to upgrading it to PoKeys57CNC and Mach4 as appropriate.

Updates:

12/04/2017: Ordered 6mm aluminium plates from laser cutters. 1/4" plate is unusual here in Australia so it's easier to just go with 6mm. Should hopefully arrive by 20/04/2017 so I can get them into a machine shop to drill the smaller holes and counter bore the bearing housings.

Side-by-side comparison of Standard Sphinx vs Rigid XL Y-Axis side plates. All other plates are identical to the standard build.

Update 21/12/2017

Machine has been finished for a while now and has been cutting reliably (opperator error excluded). I made some changes. The Z-Axis has a 3:1 reduction on the stepper to support the 2.2kW spindle. It does not struggle at all from what I have seen so far & I have even dropped the motor current down to under 2 amps, ensuring the stepper doesnt get too hot.

The back to back extrusion is incredibly rigid. I have not got the tools or a technique yet to measure it accuratly yet but I feel confident there is no deflection in the gantry that would limit the quality of parts produced by a machine of this nature.

A little more mass to reduce vibration would be a good thing. I have also had some frustration with motor couplings but that is external to the design.

Prior threads:

Sphinx Solidworks files & XL Build plan

MOAM Industries

Reference Builds:

C-beam Sphinx

Sphinx XL

Sphinx rigid XL

Build in 'Cartesian Style CNC' published by Apothus, Jan 10, 2018.

Rigid variant of the C-Beam sphinx platform

-

-

-

- Build Progress:

-

- Build Complete!

NANANG RONI WIBOWO, stefanopze, Alexandrerex and 8 others like this. -

-

Build Author Apothus, Find all builds by Apothus

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution Share Alike - CC BY SA

-

Attached Files:

-

![[IMG]](proxy.php?image=http%3A%2F%2Fi.imgur.com%2F3Q35kQ7.jpg&hash=4de9e5b88a24a320d8be08ac304e24ba)

![[IMG]](proxy.php?image=http%3A%2F%2Fi.imgur.com%2Fj95FNNP.jpg&hash=cf1d99cdd2e758535541317c9b81fad7)