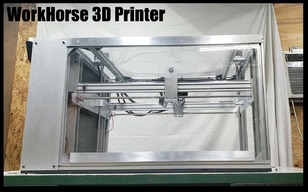

Workhorse 3D Printer

Discussion in '3D printers' started by shanehooper, May 26, 2019.

Workhorse 3D Printer

Discussion in '3D printers' started by shanehooper, May 26, 2019.

Large 600mm x 350mm x 350mm Build Volume with lead screw driven motion. The printer build has a moving gantry and fixed heat bed. Open Source