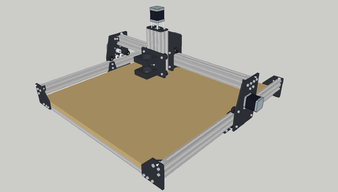

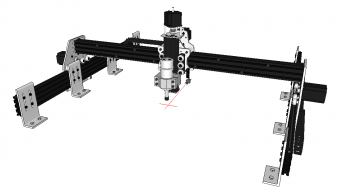

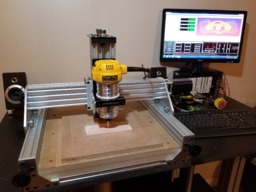

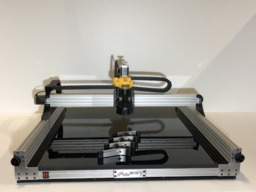

Cartesian Style CNC

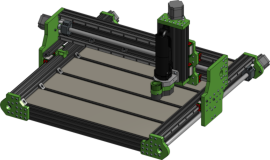

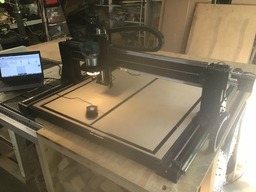

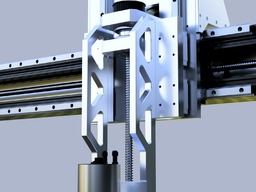

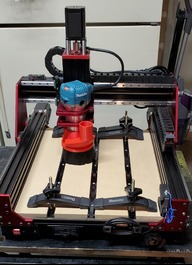

LEAD 1515, HGH15, SFU1604 Ball Screw

Project Completed.

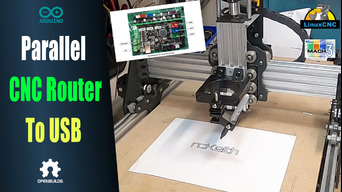

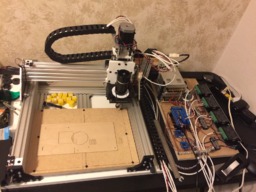

Techsoft Roland TS-30 rebuild

Replacing the Electronics and Spindle. Intending to rewire all the buttons and make it into a more modern and easy to use CNC.

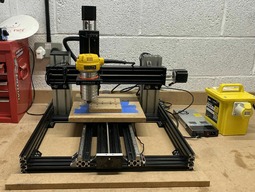

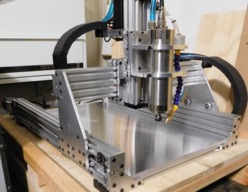

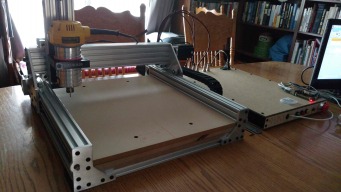

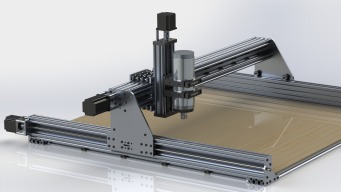

Small Desktop CNC Router/Mill

I designed and made this from scratch. The frame is welded steel filled with sand, and most of the other parts are aluminium. It's controlled with a DIY ESP32 controller running GRBL_ESP32

Gerber 404 Retrofit

Not sure if the Blackbox X32 is the right option here, just looking for guidance.

Build Author

Scott Drake

Views

15977

Build Author

Scott Drake

Views

15977

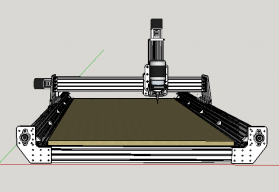

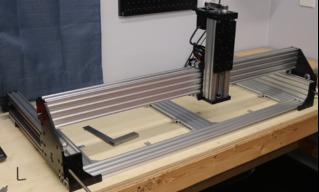

1500x1000 CNC Router

1500x1000, additional frame stiffening from laser cut Stainless steel bracing plates, Nema 34 motor upgrade and Hiwin 16mm ballscrew additions on the way. Ethernet Smooth stepper control, 2.2kw Water cooled spindle. Schneider atv320 variable speed drive. SICK inductive limit switches, Leadshine Em882S stepper drivers ,1kw 62V supply for Stepper drives

Build Author

Michael.M

Views

37277

Build Author

Michael.M

Views

37277

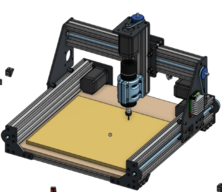

7050 Sphinx

This is a Kyo Sphinx CNC Router build. Working Area: 350mm X 500mm Link to original design: https://openbuilds.com/builds/c-beam-sphinx.3605/

Build Author

StrictlyScale

Views

7235

Build Author

StrictlyScale

Views

7235

Lead1010 Build with Enclosure

First time CNC builder puts together a Lead1010 machine.

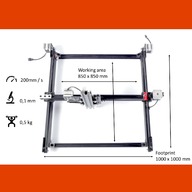

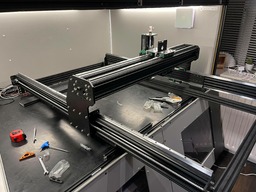

HYDRA multi tool CNC , based on ACRO

modifying ACRO

"Hirata scrap find" CNC

First CNC and first attempt at building one also, so yeah... good luck to me!

Build Author

Kyo

Views

23104

Build Author

Kyo

Views

23104

Sphinx 55

A Sphinx build to inspire and encourage all those who want to get started with cnc to check out Opensbuilds line of machine bundles and hardware.

Build Author

Frank Del Favero

Views

5785

Build Author

Frank Del Favero

Views

5785

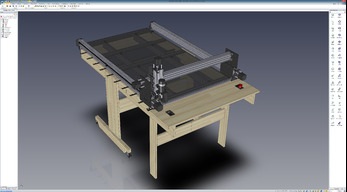

Portable self-contained Lead 1010 table

I have a two car garage NOT devoted to 3d printing or CNC. I have set aside a space for my 3d printer and a place to store my portable CNC table. The reason it’s portable is so that I wheel and can use my Lead 1010 outside where it won’t make a mess in the garage. The table is self contained. It houses a vac system as well as my CNC tools and supplies.

Build Author

Ryan Lock

Views

125948

Build Author

Ryan Lock

Views

125948

WorkBee CNC Machine

The WorkBee is our latest CNC Machine and is a culmination of all our experience, feedback, and suggestions from selling the OX CNC Machine over the past 2 years. The WorkBee is capable of accurately cutting foams, woods, plastics or aluminum at depths greater than 25mm to 0.2mm accuracy or greater.

Build Author

CONUCON

Views

3421

Build Author

CONUCON

Views

3421

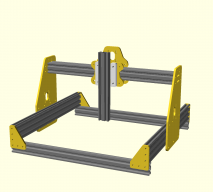

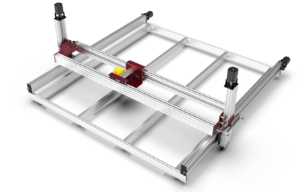

3DTwinX Gantry CNC System

Belt driven 3-axis linear system for high precision and low costs. > Threading and linear real cutting needed

LR/BS CNC Router

An easy to source/easy to build, yet quite robust CNC router. This design has not yet be implemented.

Build Author

Ryan Lock

Views

130270

Build Author

Ryan Lock

Views

130270

Ooznest OX CNC Machine

The Ooznest OX CNC Machine Kit is based on the OX CNC Machine designed by Mark Carew, and it incorporates many upgrades from this community. The plate designs in our kit are based on the originals. However we have added our own touches to increase the performance and design of the machine. To complement Mark's build videos, we have made a complete written instruction manual, with IKEA'eske assembly diagrams.

Build Author

Kyo

Views

32583

Build Author

Kyo

Views

32583

Sphinx 1050

This is going to be a Sphinx 1050 build. Starting off as a stock kit build using industrial electronics and opensource control software. Mods and upgrades to follow.

Salmon Sphinx 1.0

A tribute build based on Kyo's wonderful CBeam Sphinx. My hope is to improve on that build slightly, but to be honest, I'll probably just screw it up. I'll use this build to publicly document my failures.

Build Author

Suhmanda

Views

2505

Build Author

Suhmanda

Views

2505

DIY CNC SPINDLE

CNC SPINDLE FOR DIY ROUTERS AND MILLING MACHINES ITSRS-985 MOTOR HAS MUCH BEFINITS THAN ANY OTHER DC MOTOR IN MARKET

Build Author

Rob Taylor

Views

16326

Build Author

Rob Taylor

Views

16326

M4: 1510SS Heavy Mk.I

A 1500x1200mm, 20mm rail and 1610 ballscrew, heavy-duty, four-axis gantry machine. As high speed as spindle power MRR will allow for. Approx 4 x 3 x 1ft travels, intermediate size between benchtop and floor-scale units. Aiming at $10-15k machine in the $3k region.

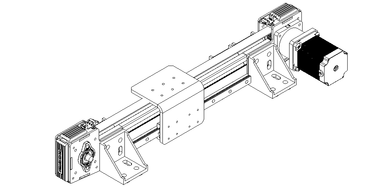

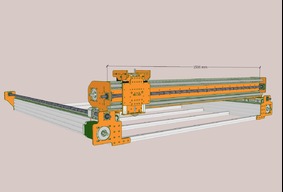

CNC Linear Slide for DIY project

Low cost cnc linear drive for making any xyz cnc structure

Build Author

Ryan155

Views

9456

Build Author

Ryan155

Views

9456

RIGCNC

I made a mill from first principles because I didn't like any of the ones that were out there, More info can be found on the website RigCNC.com

Build Author

that-jim

Views

42373

Build Author

that-jim

Views

42373

LINEAR RAIL SPHINX 55 (Blue OX plates)

Machine based on Sphinx 55 built with linear rails.

Build Author

UltiBots

Views

34993

Build Author

UltiBots

Views

34993

UltiBots CB3030 CNC Router

The UltiBots CB3030 CNC uses C-Beam, V-Slot and an extruded aluminum T-Slot work table. This allows 6mm T-Nuts, step clamps and blocks to secure materials to the work surface. The all metal design makes the use of a mister possible.

Monster-not-so-mini-mill

My Minimill hit the gym, and isn't so mini anymore

Custom 4x4 CNC

I started designing and ordering parts for this build back in Oct 2021. Unfortunately life got in the way and I had to sideline the project to deal with more important projects. I am now back working on this project full time. I originally was building a MPCNC on this torsion box platform I built but quickly realized how difficult it would be to produce anything with good accuracy. So I decided to design my own CNC that would be more robust and accurate.

Build Author

Mark Carew

Views

1165750

Build Author

Mark Carew

Views

1165750

OpenBuilds OX CNC Machine

OpenBuilds OX CNC Machine. A strong easy to build shop CNC router that can be sized to suit your needs. Many new features have been incorporated into the OX to make it a great router that is sure to inspire!

Build Author

Ted Moyer

Views

3948

Build Author

Ted Moyer

Views

3948

LEAD 1515 HIGH Z MOD 4KW ER20 7.5 KW VFD

OLD Lead 1010 High Z Mod converted to Newest Lead 1515 with High Z mod, slimmer cbeam motor mounts, thrust bearings etc. Extended by original table out and upgraded my 1.5kw VFD and Spindle to 4kw ER20 Spindle and 7.5kw GT VFD

Lead 1010 First time build

First time build of the Lead 1010 CNC with the High Z add on.

Sphinx 55 on MGN12 linear rails

My machine is a combination of the Openbuilds Sphinx 55, MGN12 linear rails knockoffs and custom made plates made by Chris Laidlaw

1010 with linear rails

Has a 700 by 700 cutting area and is very stable

Build Author

ahayden

Views

25318

Build Author

ahayden

Views

25318

C-Beam Prefab Untitled

The C-Beam Prefab Untitled is designed as the cartesian compliment to the C-Beam XL. With the exception of requiring a couple more 1000mm C-Beams and lead screws, the build requires a minimum of additional parts. The primary intention of the build is to maximize the cutting envelope while still staying within the sweet spot for C-beam rigidity. This design can easily be modified and allows for further custom structural components to be cut with the initial build platform.

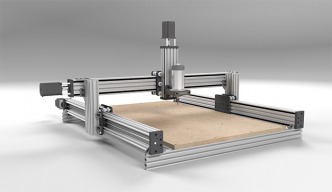

Desktop CNC

A desktop Cartesian CNC router

Build Author

blterry1

Views

16680

Build Author

blterry1

Views

16680

The Beeline CNC

Here are the instructions to build the Beeline custom CNC router table.

ACME OX (A Lead Screw Driven Ox Derivative (850x1500))

Another build based on the original OX design with a cutting area will be about 26" (680mm) x 50" (1300mm) and driven by lead screws.

Shawn's Workbee 1510

Shawn's adventure in assembling and customizing the Openbuild's version of the 1500x1000 Workbee.

Build Author

Scott Martinez

Views

10363

Build Author

Scott Martinez

Views

10363

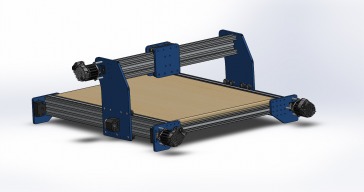

The Growler

This machine is a heavy duty, moving gantry style CNC router. It uses Teknic ClearPath servo motors driving ballscrews and linear rails. The machine has 36" x 48" x 19" of travel with about 7" of clearance below the gantry.

Build Author

Jay Almers

Views

6509

Build Author

Jay Almers

Views

6509

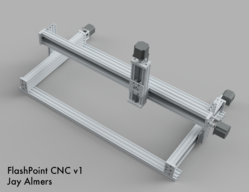

FlashPoint CNC v1: 500mm x 1000mm 3-Axis CNC Router

My build is based on many different builds but pieced together into a unit specifically to suit my needs. The footprint, without motors, is around 500mm x 1000mm with a gantry height of around 250mm. I used a combination of C-Beam, for the linear transmission, and V-Slot for the base and gantry supports. Forged angle connectors were used for attachment and I utilized the C-Beam gantry cart kits with anti-backlash blocks for both Y axes, the X axis, and Z axis.

Build Author

Serge E.

Views

59178

Build Author

Serge E.

Views

59178

myOX : a 4' x 2' OX CNC with potential

This is the story of me building myOX - my version of the "ideal" OX. I want a machine which can route/mill at least 4' wide and as long as I can feed through (don't be shy, think "infinity") as well as going deep on multiple faces - manual 4th axis. I have loads of ideas to take myOX towards that goal and way beyond. Time will tell. Just follow along through this build and possibly a few others along the way ... Check out my OXCalculator : let your computer figure out your BoM

Homemade CNC

This started as an attempt to learn to weld and quickly took on a life of its own.

Ooznest Ox with 3D Printed Gantry Plates

Ooznest Ox with gantry plates and end caps 3D printed in ABS rather than aluminum.

C-Beam XXLarge "Tank"

This is a modified build C-Beam XLarge. 1000mm C-Beam used for X and Y axis, and the Y Axis moves the X bridge, not the material being worked.

The RAT. A form ply and aluminium hybrid.

A hybrid of form ply and aluminium. 835x1260x100mm working envelope.

Promoveo Study Builds

Promoteo Build

Build Author

Savvas

Views

18260

Build Author

Savvas

Views

18260

C-Beam Lead Screw CNC Mountain

I’m making a desktop CNC machine based on the C-Beam platform. It will be driven by Tr8 Lead Screws, and initially made from 12mm birch ply plates.

Build Author

T4Concepts

Views

72710

Build Author

T4Concepts

Views

72710

WorkBee CNC build - My honest opinion, tips and help

My main goal for my build is to have a machine that is capable of profiling and help me in my designs, for the manufacture of custom automotive headlights.

Build Author

Shaun Weitzel

Views

4948

Build Author

Shaun Weitzel

Views

4948

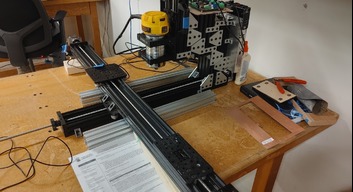

OpenBuilds Lead 1515

First build of a Lead 1515!

Another C-Beam machine

This is basically a Sphinx variant with few changes of my own...hope it'll work.

CubeFoot CNC

This small desktop machine is built inside a 300mm cube of 20mm extrusion. Work area is 14cm by 14cm. I used 400 step nema17 motors all around.

Build Author

Michael.M

Views

62041

Build Author

Michael.M

Views

62041

GRANITE 1.0

This machine has been in the works for quite a while. Most of the plates were cut with my Shpinx machine. I have a lot more photos and information to share soon.

Build Author

Mike Campbell

Views

9361

Build Author

Mike Campbell

Views

9361

bor 454-D

A large format, modular, rack and pinion build designed around OpenBuilds components.

My C-Beam build and modifications

Modified C-Beam which I plan to add a laser module and eventually convert to C-Beam XL size.

Prototype Rack-n-Pinion 4'x8'

This is a custom gear rack drive machine with a 4'x8' cut capacity.

OB Lead 1515 CNC Router 2021

Building the OB Lead 1515 was straight forward. The on-line OpenBuilds assembly videos were extremely clear and easy to follow. Initial build of this machine is with OpenBuilds BlackBox which simplified getting the electronics to work the first time. OpenBuilds staff are friendly and helpful.

Black gear 1500X3000

My cnc update and rebuild.

The Beast

1000mm x 1000mm linear rails, double gantry, build in Process... more to come

Build Author

Steve Hall

Views

3193

Build Author

Steve Hall

Views

3193

Cartesian Style Build UK

Another Cartesian style build with parts from the UK, US & China.

Lead 1510

Customised Lead 1010 making it a 1510. T-Track work area with dual Y limit switches for auto-squaring. Powered by xPro v5 & CNC.js

Build Author

Paul Amelang

Views

3784

Build Author

Paul Amelang

Views

3784

4x8 CNC Router for Composites

Router for making plugs for composite part production, and for cutting CFRP.

Viking OX

My OX cnc upgrade.

Build Author

evil2002usna

Views

10534

Build Author

evil2002usna

Views

10534

Evil Ox

Cheap Ballscrew Ox CNC Router.

C-BEAM-GTC

Building a larger C-BEAM CNC Machine with no previous experience.

Fastmill CNC

Very cheap CNC made from laser fired and bent parts.

A very affordable CNC routing

In progress CNC, (just design for the momment), I want to get some feedback about the design and the possible flexion of the aluminum profiles chosen

Ooznest OX CNC Build

Ooznest OX CNC build

big_recnc v2.0

cnc made with a 6mm metal body .

HD CNC

Heavy Duty build with 1605 Ballscrew and Linear Rail

Build Author

Wes Dwight

Views

6161

Build Author

Wes Dwight

Views

6161

Modified Sphinx 55 with MGN12 linear rails

Inspired by previous Sphinx builds by Sorin (w/ MGN Rails) and Kenneth's witthuhnCNC XKLBR-1S. I wanted to create a desktop unit that kept a minimal profile and neatly contained the PS, Controller, and all wiring, making it a singular unit that could be easily transportable (as it will be doing double duty at my home and at work)

Build Author

ckgottabuild

Views

2814

Build Author

ckgottabuild

Views

2814

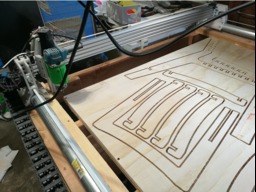

Lead CNC 1010 Platform and Rotating Laptop Mount

Moveable Lead CNC1010 build with handles on four corners. Everything fits on one sheet of cut out 4x8 plywood

Build Author

Kyo

Views

139426

Build Author

Kyo

Views

139426

C-beam Sphinx

A strong desktop cnc router that will enable you to make larger aluminium plates without taking up to much room. Simple, strong and opensource ! Build one today..

Gigantesque CNC

This is a upgrade to make a little deeper and a little bigger foot print for cutting. This is a copy of design off Rob Taylor idea for Dbl C Beam setup. The goal though is to design it around a new build with minimal tools for some one with no cnc access. Drillpress and drill bits and tap set. A 10in Non ferrous metal cutting blade for my table saw. Paper printer for printing DXF files.

Workbee with less irritations

My workbee build with some add ons

Build Author

Stokrotka74

Views

5785

Build Author

Stokrotka74

Views

5785

Racoon CNC

This is a Sphinx variation, aimed to minimize footprint and maximize workarea. Work in progress.

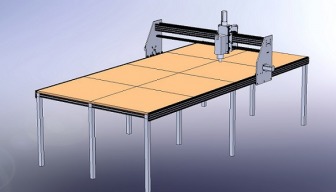

3000x1500 CNC

Here is my Project A CNC 3000 mm by 1500 mm, with a 2.2kW spindle collet ER25 and 4 stepper motor nema 23 425oz-in. The purpose being to have a large work surface for a minimum cost.

Build Author

CNCGear

Views

8742

Build Author

CNCGear

Views

8742

The BlackBee CNC

Ball screw drive, linear rail CNC Kit

Build Author

C-CNC

Views

12642

Build Author

C-CNC

Views

12642

Gantry Style CNC from plywood

I am currently 15 years old, from Germany and trying to build a low budged CNC router. I only designed this CNC based on other CNC routers that I have seen and what I am able of. It consists mostly of 2.3cm plywood to keep costs down. The size of the work area is approx. 40 x 80 cm. I would be really glad if you could give me advice's for improvement on the design and everything else ... ( I could really need your help :) ) enjoy :)

Sea-OX

This is my first CNC build. The Sea-OX is a machine built out of three 1000mm C-Beams. I plan to have a Y length of 1000mm and a X length of 650mm. The Z should have the ability to move approximately 100mm.

Build Author

mathom713

Views

8650

Build Author

mathom713

Views

8650

27" by 40" CNC

DIY design and build of a roughing 2' by 3.5' CNC router

Build Author

Corey Corbin

Views

5189

Build Author

Corey Corbin

Views

5189

Ball Screw Carrier.

Create a ball screw carrier with out BF BK bearing blocks.

Plastic Monstrosity

Large inexpensive build that can cut a 4x8 ft sheet with room to spare. Can be built using only a 3D printer and standard parts -- no special CNC'd plates required.

Bessy 4x4

I found this to be a very fun exercise in building Bessy and will continue to improve her in the future.

The BEE and ME

I have always wanted to work with CNC machinery...a few years back I got my chance to learn some basics at the Double Glazing Company where I was employed (very basic I might add) before the firm folded and I was made redundant...I wanted to continue learning and when I came across this site which push affordable machines I thought I'd give it a go. So I purchased a !000mmx750mm Screw Driven Workbee from Ooznest and I'm about to embark on my quest as many have done before me...Wish me Luck!

Retractable WorkBee1510 with Marlin+MarlinPanel high level build

WorkBee1510 with retractable space saving stand and customize build Marlin firmware and MarlinPanel (GCode Sender/UI)

Build Author

Vin1027

Views

6184

Build Author

Vin1027

Views

6184

C-Beam Sphinx

This is the original C-Beam Sphinx with the 16 wheel X gantry plates. I'm using the Ethernet Smoothstepper, Gecko G540 stepper driver and Mach 4 for motion control.

Build Author

Joe F

Views

7049

Build Author

Joe F

Views

7049

Rack and Pinion Cartesian Mill

This is a rework of a previous build I did on here, a mostly printed cartesian CNC. Initially intended to just be an update to that, but so many things changed including the linear motion and every single part has been modified significantly that I felt as though it deserved a whole new build.

Ox with Gecko Controller and CNC Linux

This build is the documentation of someone with no experience building the OX cnc machine with a Gecko G540 controller and CNClinux

Build Author

Jacob Lotter

Views

22359

Build Author

Jacob Lotter

Views

22359

1510 Workbee Modified

Some of the things that I have done to my 1510 Workbee Installed Linear rails and bearing blocks with drawings. Installed Ops console Made conversion plates for extruded aluminum to casters Extended z axis travel by a couple inches with steel plates. As of now in the process of installing Lead screws across the 1500mm length.

AcoustoPlot3D

The Sphinx has all the components I need, except it will need a taller vertical lead screw, the same length as the horizontal ones. It will also need legs. So I need to start with the Sphinx parts list, then make a few changes.

Build Author

Colin Russon

Views

3093

Build Author

Colin Russon

Views

3093

TITAN GAMBIT

Anti-Twist Design, larger lead screws, enhanced M8 wheel sets.

Build Author

sebf34

Views

30555

Build Author

sebf34

Views

30555

OX Based cnc 3000 x 1500 Double belt

OX Based CNC

Build Author

mytechno3d

Views

24624

Build Author

mytechno3d

Views

24624

Router / plasma cutting table ( Rack and pinion )

Heavy DIY plasma cutting table

LEAD CNC 1010 Laser Modification

Easy All-in-One Laser and Mounting Kit for your Openbuilds CNC.

Big Ox Heavy Duty

A Heavy Duty version of the standard Big Ox build.

My build

I am satisfied with my build and next one will be even better.

Mini-OX

An OX-inspired mini desktop mill. Designed in OpenSCAD, these parts are fully parametric and can be customized to your liking.

Charging Ox CNC Machine

A heavily modified Ox CNC build to replace SO2.

Build Author

Corey Corbin

Views

3898

Build Author

Corey Corbin

Views

3898

Sphinx Derived Router

I Like the Sphinx design thought I would attempt my first build. I wanted to build this and use Arduino controller with GRBL to be able to learn and understand my machine.

My giant "WORKBEE" 1750mm X 1750mm by ooznest

CNC MACHINE WORKBEE'S table making

Build Author

Apothus

Views

21072

Build Author

Apothus

Views

21072

Sphinx rigid XL

Rigid variant of the C-Beam sphinx platform

Build Author

Kenneth Witthuhn

Views

7439

Build Author

Kenneth Witthuhn

Views

7439

Openbuilds CNC (witthuhnCNC XKLBR-1S)

Based on the popular C-beam / V-wheel design, with the largest available work area, relative to machine size. Screw driven with anti-backlash, integrated drag chains, Carbon fibre gantry plates, Openbuilds BlackBox Controller (USB), Transformer & kill switches, with internal wiring, limit switches & Nema 23 motors.

Build Author

Yosmany325

Views

1658

Build Author

Yosmany325

Views

1658

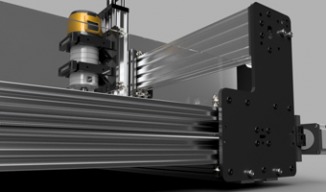

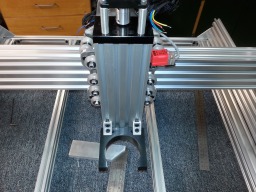

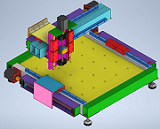

OrionPlus

Cartesian style CNC with a working area of around 360mm x 360mm x 120 mm (X, Y, Z) using Linear rails and ball screws. The linear rails are (Hiwin?) HGR 20mm x 520mm and the ball screws are SFU1204 (12mm lead 4mm) of around +/- 430 mm. The base structure is made from rectangular aluminum profiles of 70mm x 45mm x 3mm (thickness of walls).