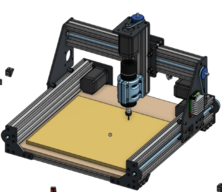

Racoon CNC

Discussion in 'CNC Mills/Routers' started by Stokrotka74, Nov 13, 2020.

Racoon CNC

Discussion in 'CNC Mills/Routers' started by Stokrotka74, Nov 13, 2020.

This is a Sphinx variation, aimed to minimize footprint and maximize workarea. Work in progress.