Idea is to swing stepper motors inside. and use belts to transfer torque to leadscrew and increase it a bit along the way.

overall concept can be seen on my Onshape.

Still figuring out where to put end stops, drag chains and electronics.

kinda leaning toward putting drivers near stepper motors, and avoid all those long cables inducing EM noise.

This design uses mini wheels exclusively.

only one wheel holding z-axis beam is fixed, all others are on eccentric mount, that should allow easy squaring of spindle (seen this s an issue in other builds)

bottom plate on z axis is probably not needed, leadscrew can be lock in place by pulley and collar around bearing in upper plate, and this would allow to remove/replace whole z axis assembly easily (toolchange? ;-)

update 6/12/2020

I started build.

I decided to go with 1500x1000 version for a prototype to see for myself if there will be issues of deflection on such long X axis.

Made prototype plates ouf of 6mm ply on my 3018 and assembled base frame.

For a frame, i came to idea to assemble it vertically:

screwed Y axis C-Beams standing 750mm apart to a slab of MDF, making sure they are squared,

than screwed 2060 crossbeams like a ladder, one C-Beam acting as it finished assembly,

and other just as support for central 2040 'cross-crossbeams',

i literally clamped 2040s to C-Beam so they stayed inline, parallel, and squared while screwing corner brackets.

after going all way to top, screwed back plates to C-Beams, unsrcewed one thats done from mdf, unclamped, slided them apart to full width and clamped back, making sure not to introduce any skew.

than worked down screwing corner brackets between C-Beam and 2060.

than just got rid of mdf, flipped upside down, and screwed other pair of plates.

All this went smooth and fast,

in quite confined space there was plenty of room to operate wrenches and clamps from every side

and whole assembly remained parallel and squared for whole time.

Forgot to take photos.

Racoon CNC

Build in 'Cartesian Style CNC' published by Stokrotka74, Dec 6, 2020.

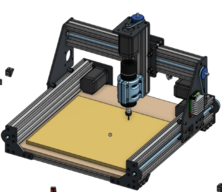

This is a Sphinx variation, aimed to minimize footprint and maximize workarea. Work in progress.

-

-

-

- Build Progress:

-

- Build in Progress...

Mark Carew, DavidR8, Metalsmith and 2 others like this. -

-

Build Author Stokrotka74, Find all builds by Stokrotka74

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution - CC BY

Reason for this Build

i really hate those stepper motors shooting out in all directions.Inspired by

sphinx cnc