A project that DEFINITELY wasn't the most efficient way of getting to the end.

I had a mini mill, but I needed juuuuuust a wee bit more length on the X-axis, and the 1m extrusions weren't that much more... so why not.

Then I needed just a half inch or so more on the Y-axis... half inch... 80mm basically the same thing.

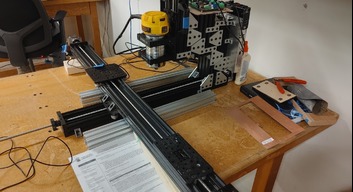

I tapped all the c-beam ends and they're all bolted together, you can see the metric crap load of joining plates to keep it solid. From what I've been able to measure, it's about as solid as the basic mini-mill.

For longer parts on the X-axis (Y-axis?? the 1m c-beam) I have a floating support plate not connected to the lead screw that I can bolt to my work piece wherever I need. Not the best , but it helps support longer pieces.

The longest thing I've milled so far is a 35 cm 2x4 and it worked out pretty phenomenally.

He's not the most prettiest little machine, but works pretty well. If you're looking at the lead screw sticking out the front, yeah, that needs to be trimmed still.

Monster-not-so-mini-mill

Build in 'Cartesian Style CNC' published by DieselDevil, Feb 16, 2023.

My Minimill hit the gym, and isn't so mini anymore

-

-

-

- Build Progress:

-

- Build Complete!

Mark Carew, Frans Frenaij, crnrstndes and 1 other person like this. -

-

Build Author DieselDevil, Find all builds by DieselDevil

-

- Loading...

-

Build Details

- Build License:

-

- CC - Creative Commons Public Domain (CCO 1+)

Reason for this Build

More space!