For this build , i do not use Openbuilds profiles ( Sorry Mark ;-) )

I need for my workshop a big and heavy cutting table who can handle both router and plasma torch .

Overall size : 2500mm x 1500mm

Working area : 2250mm x 1300mm .

Until now , i never use rack and pinion drive , it will be the first try for me.

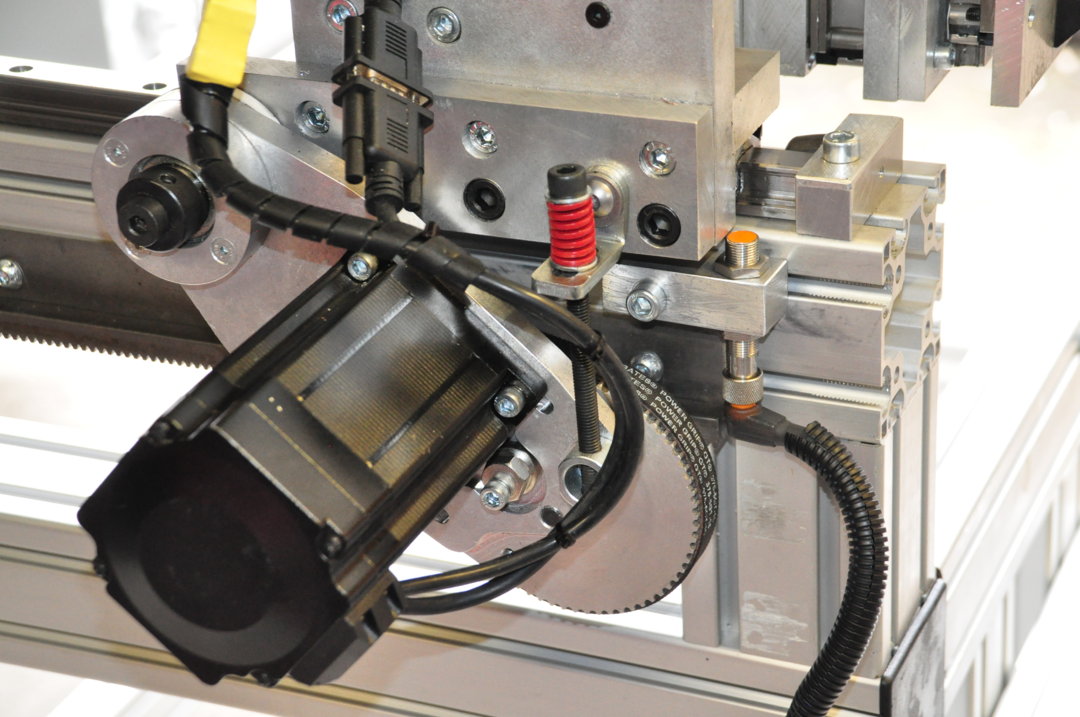

At the begining , i wanna build my own rack and pinion drive , but i finaly choose CNC router parts rack and pinion drives . Those are the only pieces that i bought already builded.

Description of the different technologies and products i used for this build :

Nema 34 hybrid ( with integrated coder ) , 8 Nm for Y axis and 4 Nm for Z and X axis.

X and Y axis are drived by rack and pinion system.

Z axis is drived by a 16mm ballscrew

Plasma Floating head

Auto scaring with two IFM inductive sensor ( Y1 and Y2 )

Homing on all axis ( X , Y1 , Y2 and Z)

Power suplly : 1 x 1200W 60 V , 1 x 400w 24V

The frame is based on a build i found on Internet and i modified it to enlarge the working area .

(I will write the source as soon i will found it again )

I made no concession for this build , so it's pretty heavy ( around 300kg ) and final price is also pretty expensive.

I made the choice to use only good stuff and of course , it have a price .

Rack and pinion drive :

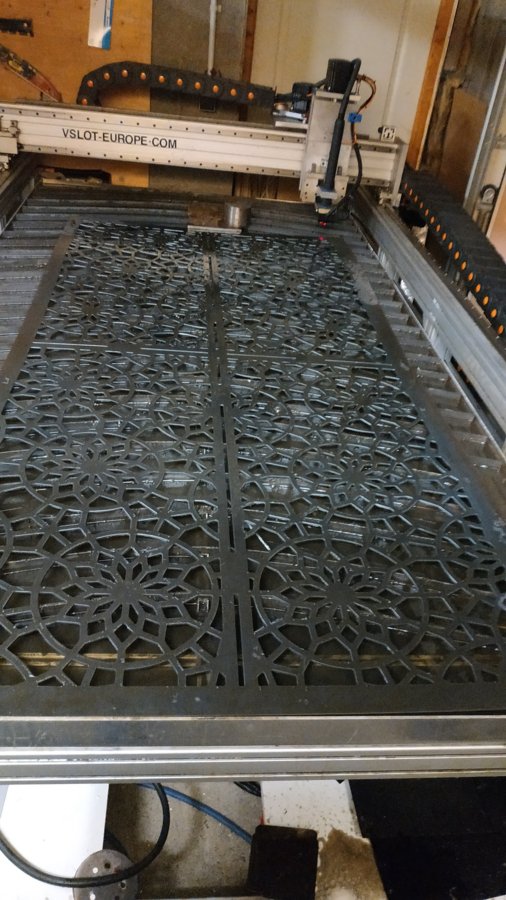

My biggest cut :

Router / plasma cutting table ( Rack and pinion )

Build in 'Cartesian Style CNC' published by mytechno3d, Jan 5, 2020.

Heavy DIY plasma cutting table

-

-

-

- Build Progress:

-

- Build Complete!

Attached Files:

ARKHAN_74, NickB, Ko/|xo3HUk and 23 others like this. -

-

Build Author mytechno3d, Find all builds by mytechno3d

-

- Loading...

-

Build Details

- Build License:

-

- CERN (CERN-OHL1.2+) Open Hardware Licence

Reason for this Build

I needed a big and strong plasma cutting table .