Build List

-

Active Filters:

b

Build Author

Hilleke

Views

6504

Build Author

Hilleke

Views

6504

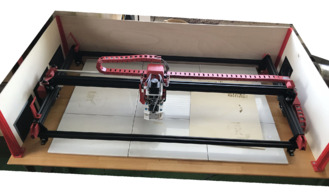

Acro System cable management and enclosure

wooden parts of the enclosure can be removed easily used the existing extraction of my glass bead burners

NotAnOx

From plywood and linear rail to c-beam. I probably should have bought a kit.

Build Author

Nicademus

Views

8122

Build Author

Nicademus

Views

8122

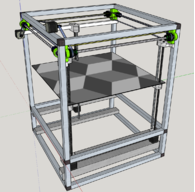

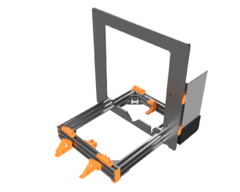

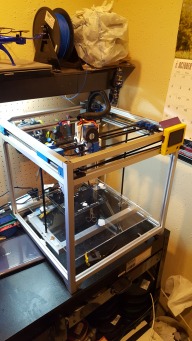

CNC/3DPrint/Laser/Mill (formerly CNC-inator3000)

Ultimately - the design is based on the highly successful Ultimaker concept, for which a regular size costs in the thousands, and one of this size would be edging into the 10's of thousands. Expected Build cost - <$800 It is a X/Y Cartesian printer with Raising/Lowering Z axis (Hotbed.) - Overall size is 610mm x 610mm x 750mm - with build volume of around 450mmx450mmx450mm - and will also have the ability to change work tools - such as for CNC Routing, Lazer etching, 3d Scanning, etc.

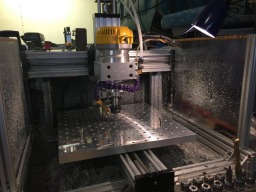

C-Beam unit with 400W Spindle

Standard (If there is one) C-Beam with plnth

Build Author

Carl Siren

Views

6348

Build Author

Carl Siren

Views

6348

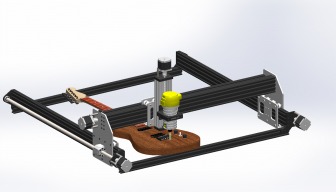

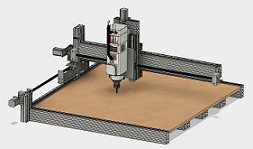

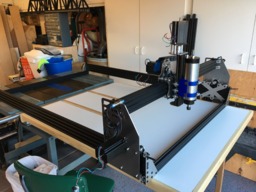

CNC-machine 650by700

A home-made CNC-machine with a 1.5 kW air cooled spindle motor suitable for milling materials such as wood, plastic and soft metals. The work table is 650 mm wide by 700 mm deep and the maximum movement is set to 560 mm for the x-axis, 480 mm for the y-axis and 105 mm for the z-axis.

HandCrafted WorkBee - HCWB

This will be a slow build as I collect parts and materials as funds permit for 1000mm x 1000mm Workbee. I call it the "Hand Crafted WorkBee" because I will be hand making the plates and as much of the build as possible using a drill press and hand tools.

Build Author

pedrofernandez

Views

10591

Build Author

pedrofernandez

Views

10591

Another Sphinx 7550 Made by an Openbuilds Cbeam

feel free to ask anything about this builds, but im a airline pilot and sometimes responding maybe will take me. while!!

Ultra MegaMax Dominator CoreXY Printer

My self-designed and built, tall-format coreXY printer with 300 x 300 x695 mm print capacity.

Build Author

Glenn Weston

Views

16715

Build Author

Glenn Weston

Views

16715

"The Moagie Mill" My C-Beam XLarge

My Experiences building the C-Beam X Large. Maybe you can pick up a few pointers from my ramblings and experiences if you are considering building this machine.

Build Author

Colin Russon

Views

8171

Build Author

Colin Russon

Views

8171

OX / X3 CNC / Similar Z axis / 1605 Linear Actuator

Z axes 1605 ballscrew, a comparative design proposal.

Build Author

BinaryConstruct

Views

9004

Build Author

BinaryConstruct

Views

9004

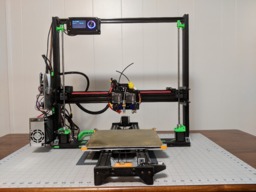

BinaryConstruct V3

This printer is a design that has evolved over three years. The original goals of this project were to design a rigid printer that had a large print volume, 300mm^3, with easily sources parts and a minimum of complicated printed parts.

Build Author

Gary Caruso

Views

23382

Build Author

Gary Caruso

Views

23382

OX Heavy Duty Build

OX Heavy Duty, using Chrisclub plates, for 2080 X-Y and C-beam Z

Build Author

Sword66

Views

9757

Build Author

Sword66

Views

9757

The Archon R2

The Archon "In the style of Cartesian movement." A brief overview, guide and summary of my highly experimental build. and some insight into the challenges of building such a large format/belted machine.

YAPCNC (Yet Another Poor's Man CNC)

Yet Another Poor's Man CNC (YAPCNC) is my first attempt to build a CNC. The idea is for the build to be as inexpensive as posible while being usable for my goals.

Build Author

Julius

Views

23680

Build Author

Julius

Views

23680

OX Balls - 1605 Ballscrew Powered 1000mmx1000mmm OX derivative

1000x1000mm Ballscrew driven OX Derivative. Dewalt 611 spindle and TB6600 Drivers.

Build Author

Sprags

Views

1874

Build Author

Sprags

Views

1874

C-Beam Kyo Sphinx 10060

More stuff here.

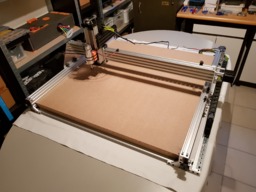

WorkBee 750x750 build

This CNC build is to help with some areas of my guitar builds - mainly inlays but some body work as well where appropriate. I expect it will be used for lots of other things once I get to know what it's capable of (sorry - what I'm capable of!).

Build Author

Mark Carew

Views

80744

Build Author

Mark Carew

Views

80744

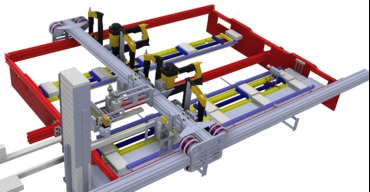

V-Slot™ Belt & Pinion Example Build

The OpenBuilds team has redefined the belt and pinion concept. By using standard OpenBuild components were able to improve on this system in ways that will save on cost and enhance its engineering capabilities.

Build Author

Beam

Views

9433

Build Author

Beam

Views

9433

DIY Flywheel Camera Slider

My take on a non affordable slider.

Build Author

jpjoshua

Views

10712

Build Author

jpjoshua

Views

10712

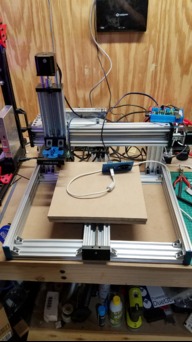

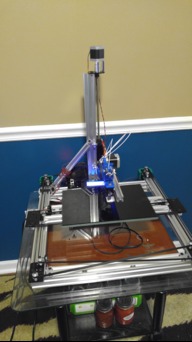

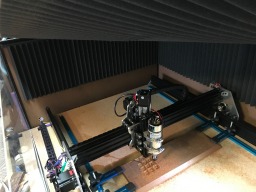

Arduino Grbl Laser CNC

Arduino powered Laser CNC using GRBl firmware.

Workbee 1500x1500 belt

Workbee CNC 1500x1500 with timing belt

Spartacus

Been using the Ox now since 2015, so decided I should move on to C-Beam :-)

frugal-ist workbee

a 1000x1000 acme screw workbee built as frugally as possible. thanks so much to ooznest and openbuilds :)

Laser engraver

Just a little light duty laser engraver.

Build Author

TurfnSurf

Views

5089

Build Author

TurfnSurf

Views

5089

3-Axis Plywood CNC

Theoretical Working area: 38" x 24" x 6" Actual Working Area: 31" x 23.6" x 4" Positioning Accuracy: about 0.01mm

C-Beam Desktop On Rails

My attempt at a Desktop CNC using C-Beam and Open-Rail with Steel Wheel bearings and LeadScrew Drive.

Build Author

Brandon Satterfield

Views

6409

Build Author

Brandon Satterfield

Views

6409

SMW3D OX

The SMW3D OX, original other than a lot of learning!

Build Author

Hussein Dermay

Views

5379

Build Author

Hussein Dermay

Views

5379

Ooznest WorkBee 1000mm x 1000mm Screw Driven

I have decided to buy and build the ooznest workbee screw driven cnc (1000x1000) and also decided to use some plates and extrusions from the ox cnc. I will never use two machines anyway and hoping to build a strong base for the workbee.

Rail Builder

glue/staple/eject 1 Axis driven Rail building machine.

C-Beam Machine XL

C-Beam XL upgraded with end-stops, E-stop, and cable chain. Running GRBL on Arduino Mega.

C_Beam Hammerhead 5x

setup for learning 5x

Workbee 1000x1000 mm screw driven Full Kit From Ooznest

A short summary of my Workbee CNC Build. I try to update it where I can

Build Author

Axnfell

Views

2249

Build Author

Axnfell

Views

2249

WorkBee 1000x2000 ACME Screw Version

Hoping to build a WorkBee 1000 x 1000 (2000) from parts and not a kit, cannot afford the kit in full so going the long way round...

Build Author

Janis93

Views

13711

Build Author

Janis93

Views

13711

1000x1000 Two version of router Belt and Screw

Cheap sheet metal gantry solutions, for diy belt driven cnc and screw driven cnc.

C-Beam Machine - MyFirstCNC

This is my first foray into CNC machines, after much review I decided on the C-Beam machine as it seemed easy to work with and will enabled me to build more and larger machines as I gain knowledge. I am planning on building the machine largely unmodified from the reference design. I will be building the machine an axis at a time as I need to spread out costs over time.

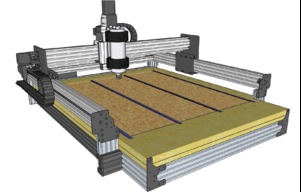

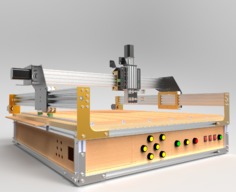

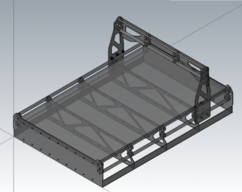

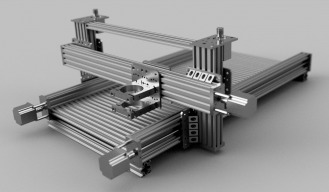

Something a Tad different

Future CNC router kit design

Build Author

Limine3D

Views

3405

Build Author

Limine3D

Views

3405

Shapeoko 1 upgrades

Replaced the original Z-axis for a shapeoko with a c-beam upgrade. This upgrade required a nema 17 mount and a quiet spindle mount I printed with a 3D printer.

Build Author

Calotype

Views

2592

Build Author

Calotype

Views

2592

My DIY panoramic rolling (&banding) Machine.

DO WHAT YOU IMAGINE !

Build Author

obmilllivebuild

Views

4714

Build Author

obmilllivebuild

Views

4714

Live C-Beam Build @ MRRF2018

Contained within are links to our OpenBuilds sponsored C-beam Machine live build taking place at MRRF 2018 (Midwest Reprap Festival) on March 24 and 25, 2018. There will also be some build images and a few 3D printed STL items that were added.

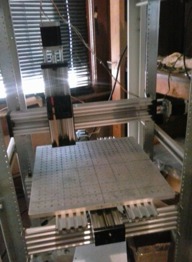

1 Cubic Meter 3D Printer

This is a at home built 1000mm x 1000mm x 1000mm 3d printer. It uses mainly parts from OpenBuild Parts and is very simple to build. The only thing that was custom was the build plate which was designed by myself and tooled at a local machine shop.

Build Author

h3rb

Views

4386

Build Author

h3rb

Views

4386

TEVO Little Monster Direct Mount Extruder

Cheap, experimental Modification to Tevo Little Monster's bowden system for the extruder

Build Author

Naomi Wu

Views

9048

Build Author

Naomi Wu

Views

9048

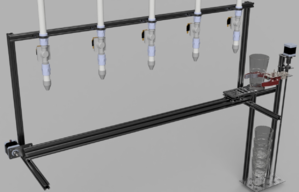

Naomi Wu's Automatic Bartender- BarBot!

This is an automatic bartender- a BarBot, designed to be made with off-the-shelf OpenBuilds, V-slot and low-cost 3D printer parts.

Build Author

uGen

Views

16979

Build Author

uGen

Views

16979

Lab Power Supply + Soldering Station

A small 32 V, 96 W lab power supply with voltage/current/power limit, program memory and an outlet to power the popular TS-100 soldering iron

Generic 6 Axis Controller

Generic 6 Axis (Stepper) Controller

Build Author

TimVukman

Views

3450

Build Author

TimVukman

Views

3450

Unique Z

My original Tevo Tarantula kit was ok..... I had issues with the X gantry staying level. I got rid of the wheels and replaced them with linear block bearings. I still had some issues with the X gantry. I swapped out the plastic parts with aluminum which was much better. Still not what I want yet

Build Author

Jose A. Molina

Views

6181

Build Author

Jose A. Molina

Views

6181

Alice Clementine

Roberta Clementine's first daughter printer Alice Clementine!

Build Author

ymilord

Views

21441

Build Author

ymilord

Views

21441

C-Beam Rigid - 'The Hog'

C-Beam Machine baseline build. DW618 Spindle. SuperPID. Gcode Controlled Mist Coolant. Rigid Work Surface. NEMA 23 (425oz-in) Leadshine 4 Axis Stepper Driver. LinuxCNC (MachineKit) Tool Touch Off Probe.

Build Author

hbtousa

Views

2326

Build Author

hbtousa

Views

2326

Quack Ball

Quack Ball is a game in which the objective is to knock down moving ducks. The ducks are protected by a barricade that moves at a very fast speed. The game can be played individually or by two or more players. Each round consists of a total of ten targets to shoot and each player will have four balls to shoot. Prior to beginning play, a player selects how many ducks, maximum four, the player will knock down continuously. If player fails games is over for that player.

Build Author

Bucky Wootmaster

Views

2255

Build Author

Bucky Wootmaster

Views

2255

Bucky CNC

CNC machine using extrusions with linear rails and ball screws on all axes - no plates

Build Author

OffAxis

Views

6350

Build Author

OffAxis

Views

6350

OffAxis CNC 1000x1500

Cut Area: 825 x 1340. Max Cutting depth: 2 inches. Arduino based control with Nema 23 and Nema 17 drive. 8mm leadscrew and 2GT belt drive. 400W 48V quite cut spindle.

Build Author

crnrstndes

Views

3151

Build Author

crnrstndes

Views

3151

C-Beam Upgrade to Larger C-Beam

My goal was to be able to enlarge my C-Beam with as many original parts as possible. I was able to recycle almost all of them with a only the two 500 mm rails left over. I used 1000 mm rails for the X Axis and I added another complete Y Axis assembly. I chose to keep it simple and I am very happy with the result!

Build Author

JAC_101

Views

4873

Build Author

JAC_101

Views

4873

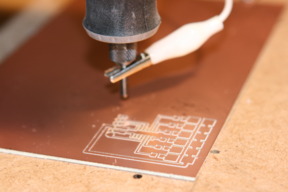

Small PCB, Engraving and Delrin CNC Mill

This is my first attempt at building a spindle based CNC machine. The intention is to mill PCB boards and mill delrin blocks. The device was built with an Emergency Stop that actually cuts power to the spindle and motors. This is a post build write-up and consists of finished photo compilation and CAD renderings.

Ooznest workbee

This is my first build so I will let you know how I get on

Beefed-up and customized OX build

My Machine is based on the OX CNC designed by Mark Carew as well as the ooznest kit, and it incorporates a bunch of my own details and revisions to increase performance and robustness. It has become way more beastly than I originally planned!

Build Author

spark2

Views

4377

Build Author

spark2

Views

4377

C-Beam - Sphinx 1000x1000mm inspired by Kyo

A stable CNC Router that allows me to cut and carve bigger Parts. The Machine is an original Build from Kyo's Sphinx CNC Machine. Thanks for the great Work and the Effort Kyo. Your Files and Lists helped me a lot to build that Sphinx 1x1m.

Build Author

Huub65

Views

7491

Build Author

Huub65

Views

7491

My C Beam - NEMA 17 - GRBL- Arduino project

Cbeam machine. Using small stepper motors (NEMA 17) and Arduino controller. Try to get this working in de upcoming month.

Build Author

Denis Lapratte

Views

3345

Build Author

Denis Lapratte

Views

3345

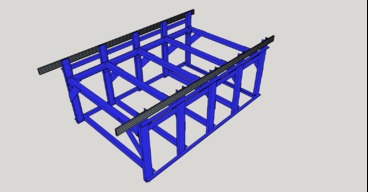

All metal Ox hybrid CNC Router Table

This is my second CNC build, but the first one that I design from the ground up. The base is all metal because I want to add Plasma facility later on. I used the Ox model for the gantry plates and made a few changes to adapt to my design. Since I wanted to use parts from my first CNC to save as much as possible, I kept the 5/8 Hi-Lead Screw I had from Roton for the Y and Z axis. I will also add a downdraft table to keep all parts tight on the table for cutting.

Build Author

bpatterson42

Views

2421

Build Author

bpatterson42

Views

2421

Inverted Y C-Beam Machine

Similar to C-Beam Machine build, but with inverted Y-axis assembly to shield drive screw. Integrated XZ gantry can be fixed to any solid surface. Build dimensions are 36" x 36" x 6".

Build Author

pek

Views

24483

Build Author

pek

Views

24483

Prusa i3 Bear Half Upgrade v1.0

Stronger frame for Prusa i3 MK2 / MK2s / MK2.5 3D printer

Build Author

Camvec

Views

5387

Build Author

Camvec

Views

5387

WorkBee CNC full kit 1500mm x 1500mm

This will be my first build ever! Looking forward to it , just gotta finish the new workshop first then I'm on it!

D-Bot Version B

D-Bot with a Replicate controller.

Dogmeat's Custom C-Beam XL

I love the C-Beam XL concept, this build is my custom version with the goal of increasing rigidity for metal milling.

Build Author

Rodrigo Gonzalez

Views

2871

Build Author

Rodrigo Gonzalez

Views

2871

Nightfuel

The user will input a selection from a variety of pre-established drinks. The user will not need a glass, since it will be provided in the automation process. This completely eliminates the need for a bartender if an RFID purchase system is implemented.

Build Author

dmasters

Views

7332

Build Author

dmasters

Views

7332

DM C-Beam XXL Tank

1000mm x 1000mm C-Beam XXL CNC with external drivers and high torque Nema 23 motors, 2.2KW Spindle with VFD.

Build Author

Carl van Heezik

Views

7210

Build Author

Carl van Heezik

Views

7210

C-Beam™ Machine for PCB milling

C-Beam Machine for PCB milling

Ox Stainless with ballscrews

Ox Stainless with ballscrews for motion, nema 23 steppers, LInuxcnc for control software. Using basic parts for frame from Makersupplies, and the rest sourced from ebay. Building a small router hoping it will be able to cut aluminum with decent results.

Build Author

Bill325

Views

1616

Build Author

Bill325

Views

1616

One more life for a cube

Modify a Gen1 Cube printer into a small cnc router to cut pcbs and light (VERY light) milling work. Also easy to swap out the rotary head and mount a laser head for engraving.

Build Author

Teflon4

Views

14968

Build Author

Teflon4

Views

14968

TZ C-Beam Machine Plate Maker

A Modified and augmented Ooznest C-Beam Machine Plate Maker.

RSW's C-Beam Build

I built a CNC Router using 3/4 MDF, 1/8 aluminum angle for bearing races and various other odds and ends. I learned a lot about how not to build a CNC router. I found Openbuilds.com and decided to build a C-Beam for my first build. The long term idea is to use this machine to build custom plates for and OX type machine and a 3d printer.

Build Author

GDanger117

Views

10298

Build Author

GDanger117

Views

10298

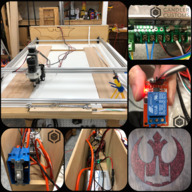

Gantry CNC - Decisions made only to change over and over.

This is my first CNC build. As per the norm, I went in with months of research, planning, and resource gathering tied neatly together with a solid plan. As the path went on, the plan continued to change to accommodate issues I hadn't counted on. But, at the end of the road, the project reached completion, and I learned a ton along the way!

Build Author

ShockingTops

Views

3529

Build Author

ShockingTops

Views

3529

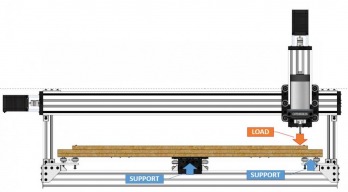

Opening into doors

Construction of a CNC table for a specific project that could cut an area larger than a door (>8'x4'). Much thought went into how to avoid the weight of the gantry bending the (long) Y axis, whilst still keeping down the complexity and cost.

C Beam Served

C Beam Machine built in a server cab. Hopefully this keeps every thing enclosed , clean and quite ?

Build Author

Bud Griffin

Views

10597

Build Author

Bud Griffin

Views

10597

BF3D OX (Big Freakin' 3D OX)

This is my latest printer build. The second printer I've built using V-Slot.

Desktop PCB Maker

With the focus always on larger builds I wanted to focus on a desktop PCB milling machine that fulfills the average users desktop needs at an entry level cost. Design considerations will allow expandable capabilities to include 3D printing and any other functions a small form Cartesian robot can perform. The current iteration has a desktop footprint of approximately 15.5" X 14.5".

Build Author

George Motichka

Views

2995

Build Author

George Motichka

Views

2995

Transformer

I wanted a machine that could easily switch between 3D Printing and Laser Engraving

Build Author

CandlerCustoms

Views

4052

Build Author

CandlerCustoms

Views

4052

Candler Customs - Custom CNC Machine

Inexpensive Custom CNC Machine or swappable Laser Engraver utilizing OpenBuilds ACRO System

OX CNC Build

OX CNC built using the kit from SMW3D with a Smoothieboard 5 and external motor drivers.

The Nguni - an OX variant

A modified OX with more X clearance, MDF plates, vacuum table

Build Author

Ronald van Arkel

Views

15294

Build Author

Ronald van Arkel

Views

15294

Upgrading the C-Beam machine

So we have new plates, stronger motors, belt drive reduction, but what should we do with them? In this article you might find the answer you were looking for as we took an “old” C-Beam machine and started to upgrade the X/Z body and added more torque and precision to the Z-axis.

Build Author

cory stafford

Views

3926

Build Author

cory stafford

Views

3926

Home built laser cutter

This is a laser cutter built with intent to use arduino as controller for a co2 cutting laser.

C-Beam Elexa

This build will be based on the C-Beam Plate Maker, with additional changes based on other builds and ideas.

Build Author

JWhitten

Views

12906

Build Author

JWhitten

Views

12906

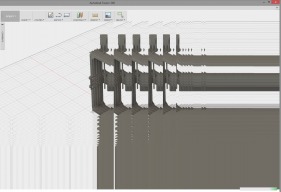

Build #2 - Bigger & Stronger

Large format CNC router with a 1500mm x 3000mm cutting envelope (5 x 10 ft) strong enough to cut wood and aluminum constructed from 20-series and 40-series aluminum extrusions. Complete Project Log w/ Pictures: https://goo.gl/photos/Co81AvGwVijE2zow9

Build Author

Jens Grabner

Views

3452

Build Author

Jens Grabner

Views

3452

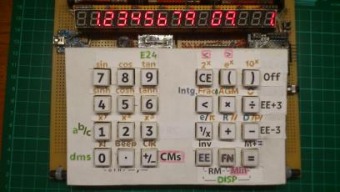

snc98_Slash-Number-Calculator

This calculator work inside with a spezail count format - Fraction as Mantisse + Dezimal exponent .. in summ 9 Byte.

SkyKae sphinx - c beam xl hybrid

I took what I thought were the best parts of the sphinx and the c beam xl to build a bigger and faster machine.

First build - small scale

Using basic standard components, beams, motors, belt drive on x and y, z is a screw. Using Grbl Panel on Windows 10. Really basic router, had trouble getting the controller to turn on the router and set speeds so it is currently wired to a power bar switch so it runs full speed and I just use the switch to turn it on and off. Just getting x, y and z control working properly for now and likely going to switch the router to my dremel 4000 using a 3d printed mounting bracket I got from thingiverse

Build Author

Tucstrlly

Views

7756

Build Author

Tucstrlly

Views

7756

Stainless OX Kit Build "Diamondback CNC"

A copy of the Stainless Ox by Martin Barfoed. Similar design, construction and control.

Absolute positioning hardware and software

Absolute linear positioning using deBruijn sequences.

Build Author

Terone Burgenheim

Views

5429

Build Author

Terone Burgenheim

Views

5429

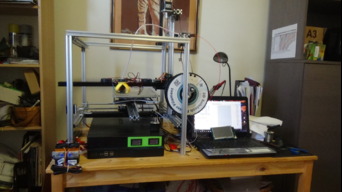

CoreXY - Tower Printer

I wanted to try a different way of operating the Z Axis so I setup a tower using 40x40. In the end it worked excellently and can easily print 60mm/s with 150mm/s travels. The coreXY is a very cool kinematic, and you can get some pretty great speed and accuracy. The main issue is the fact your Steps/mm are doubled, so the lower end motors don't like it at high speeds.

Build Author

Terone Burgenheim

Views

2063

Build Author

Terone Burgenheim

Views

2063

My CNC

This build is my version of the CBeam machine. I opted to NOT use the Gussets, and instead went for the 40, and 60 mil angle brackets to cut the price back a little further. I started with the smoothieboard but decided it was still "too new" and very much experimental. This build took me a few (2-3) days to complete. The CBeams and Lead-Screws really make building things faster since you don't have to clamor over belts.

MOJO 3D

Fast, Large build area, CoreXY design

Build Author

ZacharyB

Views

4544

Build Author

ZacharyB

Views

4544

Arizona OpenBuilds MiniMill CNC

I ordered the OpenBuilds MiniMill from the OpenBuilds Parts Store http://openbuildspartstore.com/ They were out of Motors and Electronics when I ordered so I had to source these items elsewhere. But it turned out well doing it this way.

Everything Else

Hi my name is crispin and I'm an aluminum addict.

Build Author

patdee

Views

3919

Build Author

patdee

Views

3919

777 CNC Build

To begin the "Build" I have ordered a few parts from OpenBuilds to get started. They are arriving today; according to "tracking". I cant wait! Praise Jesus! This 85 yr old man is getting a "New " life. Hallelujah and amen. Because I am building this on an existing machine, I have to be careful; so I will order some parts then see what I don't need (such as a base); along with parts that I may need to adapt it to the machine. It should be fun! "Caint wait!"

Build Author

William Niedermeyer

Views

16715

Build Author

William Niedermeyer

Views

16715

Structured Light Turntable Scanner

3d Structured Light Scanner with Arduino Controlled Turntable

Build Author

jamesdjadams

Views

11198

Build Author

jamesdjadams

Views

11198

C-Beam XL - TinyG - Aluminium Plate - Dewalt 611

C-Beam XL build using TinyG V8.

Sphinx 1000 x 500

Building a Sphinx based CNC based on Kyo's plans. Going with a 1000 x 500 table size.

Another Sphinx - 1000mm x 750mm

The reason for building this CNC is to help me in my guitar building hobby. (telecasters)

C beam machine (with larger T-slot platform)

Larger, more rigid build plate C beam machine

ZANTRY CNC

CNC Based on CBeam, with No custom Plates, and Z GANTRY

80watt Lasercutter, workingarea 105x52[cm], steel frame

I will write a short buildlog here with mostly pictures. I designed this lasercutter in solidworks(not totally finished) for a good overview and such that the steel tubes could be lasercut by a company, the metal frame is based on the lasercutter the KÄSER, which you can find on cnczone.nl. The mechical parts are designed by myself because I had no mill to my use, so the mechnical parts are lasercut(same company as tube) steelplates welded together.

![80watt Lasercutter, workingarea 105x52[cm], steel frame](https://openbuilds.com/data/article_images/l/6/6014.jpg?t=1513166610)