January 31st, 2017:

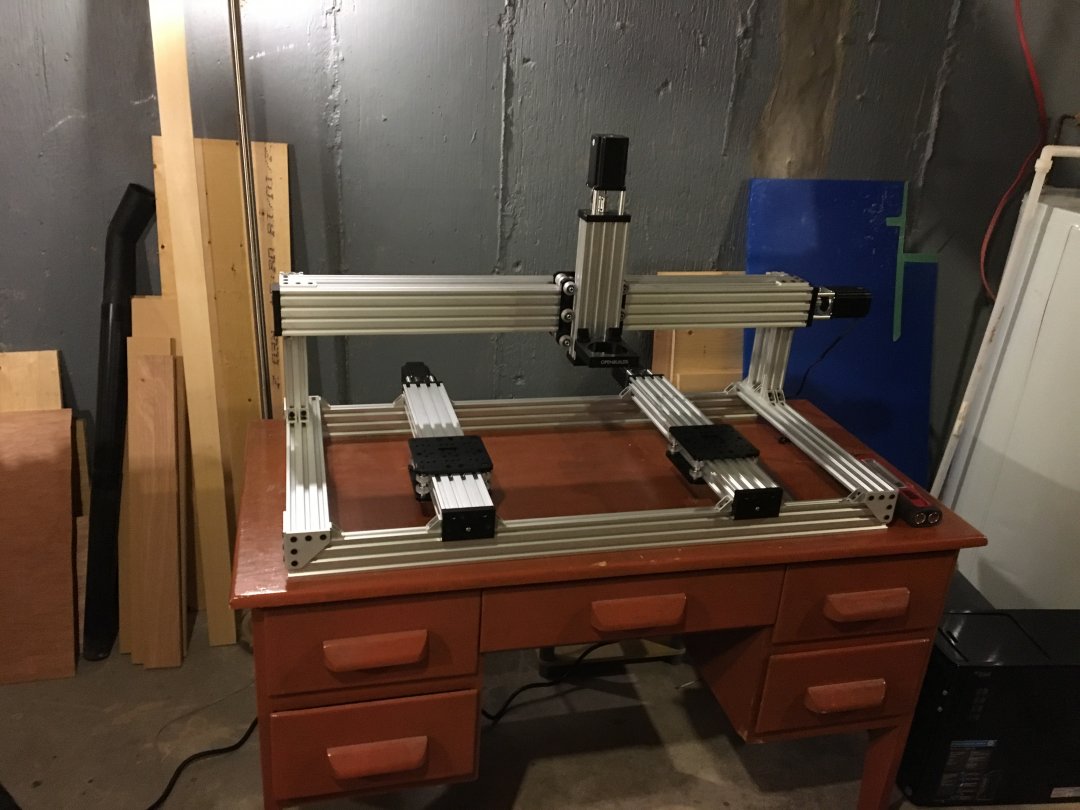

I've been thinking about taking on a project involving interfacing software to "real-life" things for some time. I was inspired by UGEARS products (Home | Ukrainian Bridge) and started looking at laser-cutters, which led me to 3D printers which then led me to selecting a CNC Mill for my first build. After doing some research, I decided to go with the C-Beam XL kit controlled via TinyG V8. I live on the east coast of Canada and it's difficult to source parts. Luckily, I found MakerParts (MakerParts.ca - Your Canadian Source for 3D Printer Parts & Filament) who were very helpful and offered excellent prices. Thanks @Makerparts

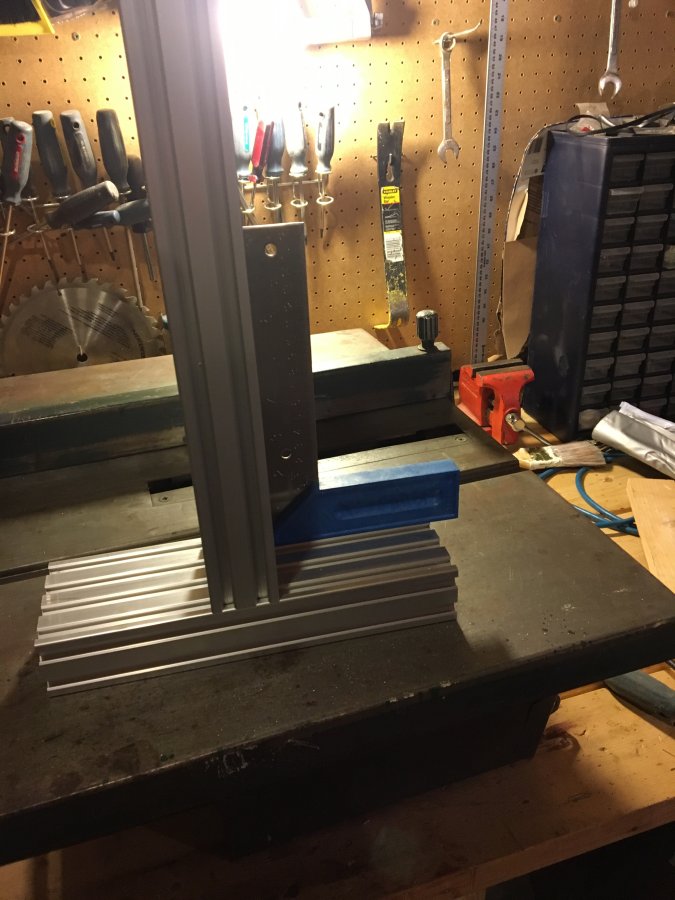

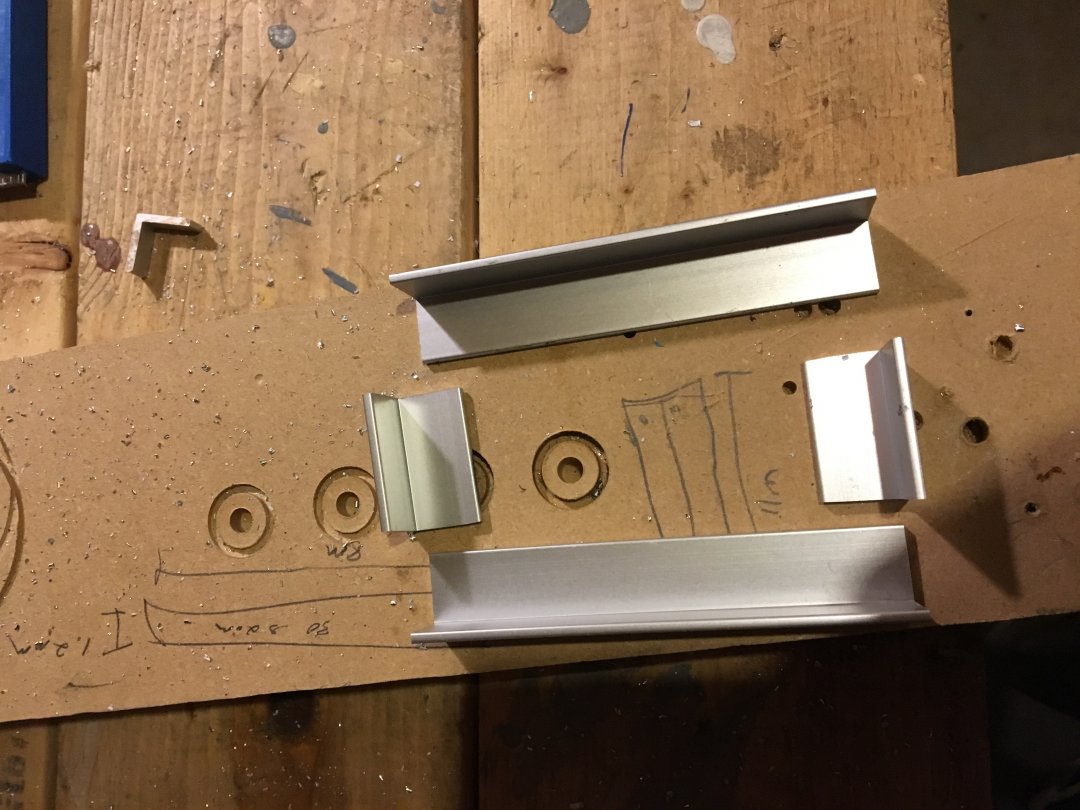

I've never worked with Aluminium before and decided to use a mitre-saw with with one of these blades and a file... a lot. In hind sight the blade worked great and I should have trusted it more than my filing. Take your time truing up your saw. It will save you hours.

My cheap saw. It's pretty cheap.

I filed, then measured, then compared, then checked for squareness, then repeated. Over and over.. Protip: follow the build instructions and tape those buggers together. I didn't and spent extra hours getting everything ready. I'm not sure why my mind ignored that part. Maybe I was having a de-motivational beer. I only noticed it afterward.

I used a M5 drill-tap bit to tap everything. Just go slow and use some WD-40 to keep the bit clean and free of aluminum chips.

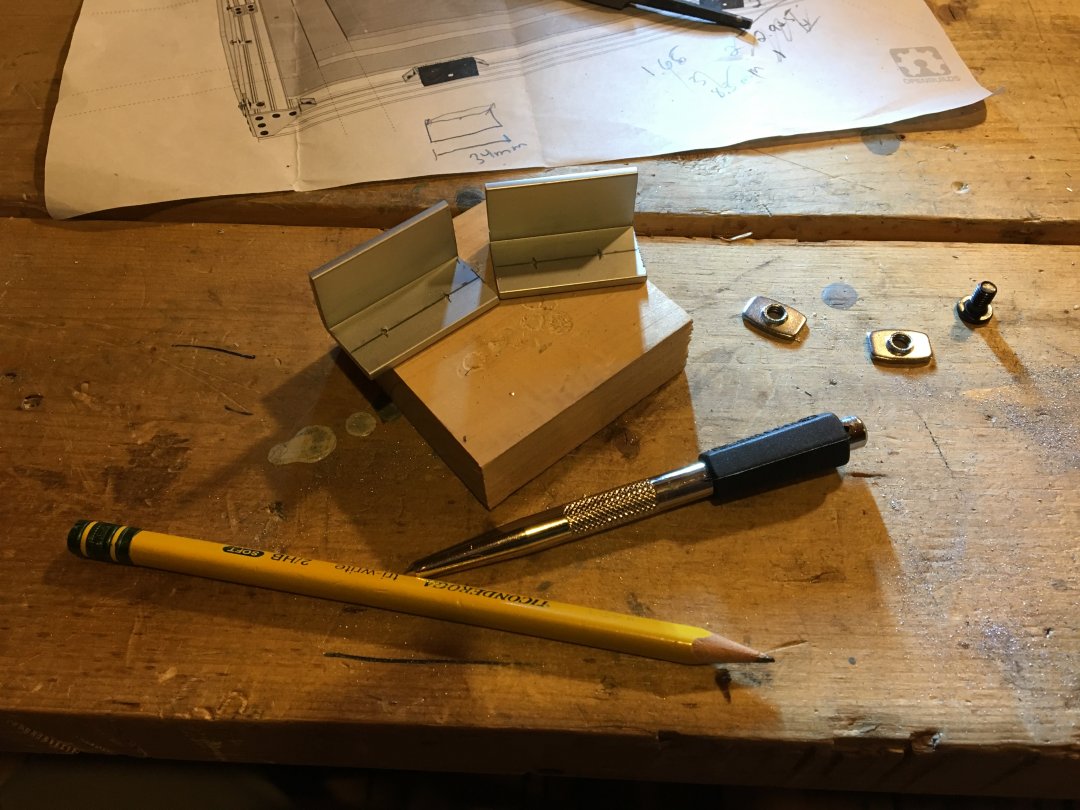

Filing nubs.

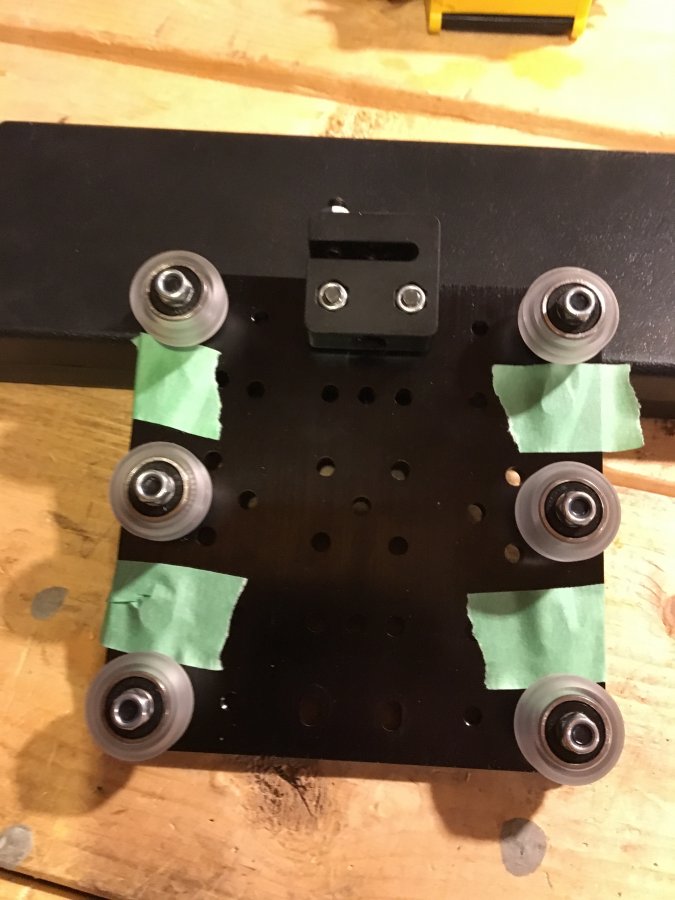

Built the mini-components. Thanks to @Moag for the awesome build guide. It was excellent.

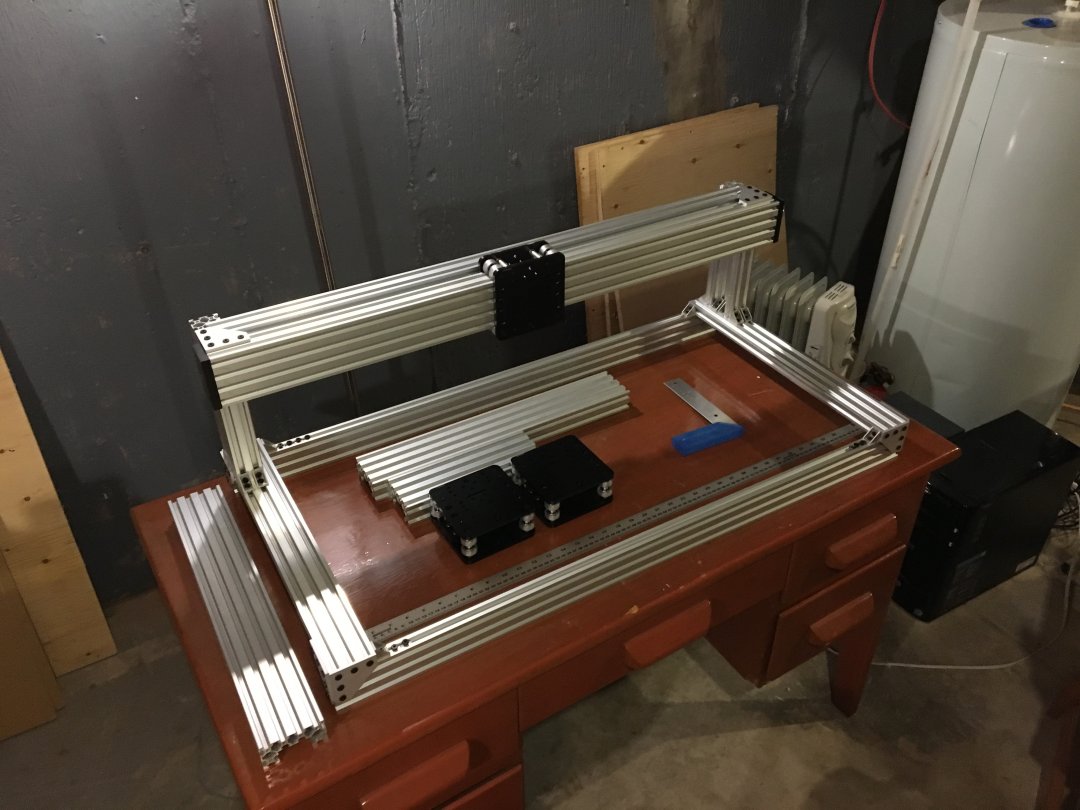

Here are a few pictures of assembly.

My Dewalt 611 arrived via Amazon.ca.

Building more mini-components. At this point I was feeling a lot like Lance Armstrong (I was missing one nut).

My advice for this stage is to not over-tighten the M5 screws. In my case, I had to fiddle with them a lot once they were on the machine. I like to over-tighten things... This caused me a few different problems through-out the build.

When reading online about adjusting the C-Beam actuator eccentric nuts, it seemed like a daunting task. It really wasn't all that bad. You just need to compromise a bit between the open and solid sides of the C-Beam and take @Moag's advice about marking the tight and loose sides of the e-nuts (new slang). I was glad that I didn't miss that step later on when re-adjusting things.

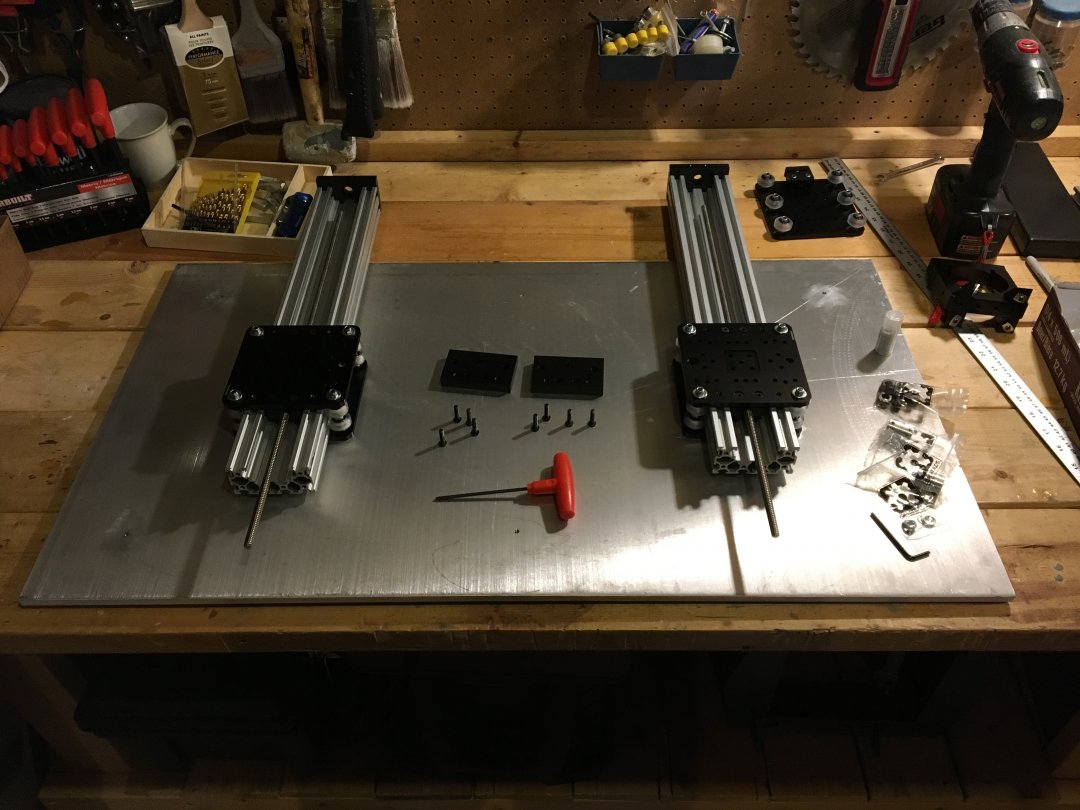

Picked up some 3/8", 6061 aluminium plate from Metal's R Us (Metals ‘R’ Us | Metal Shop Dartmouth | Home).

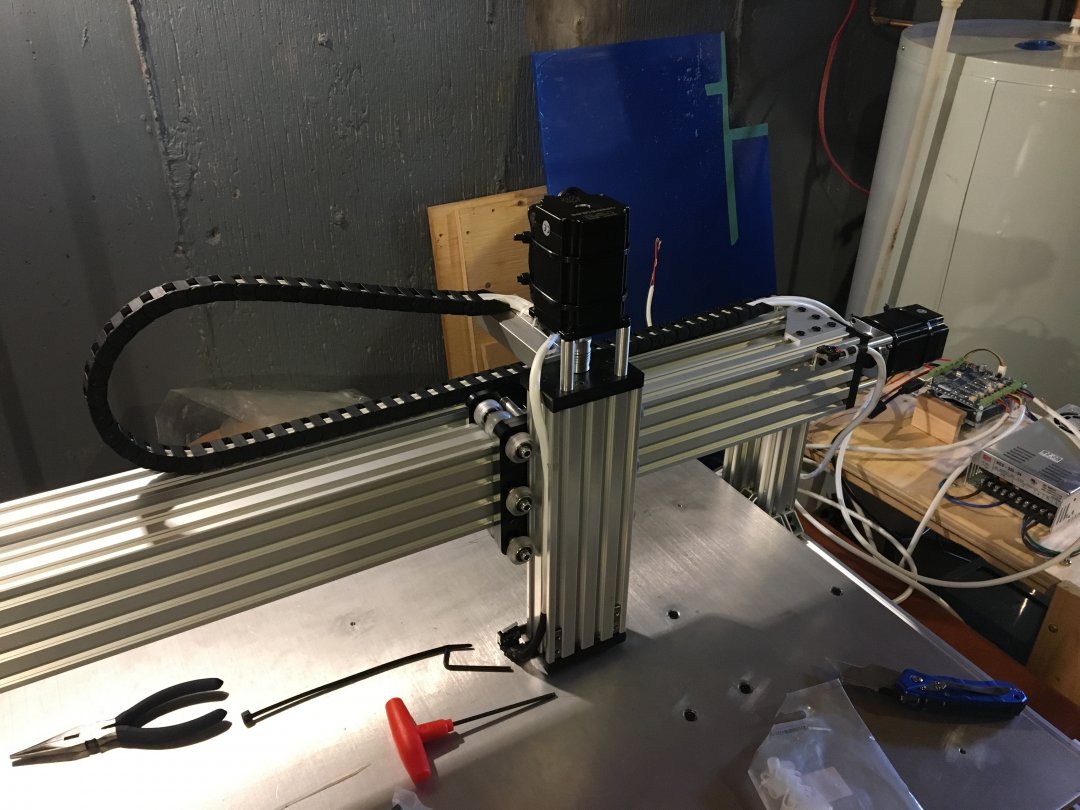

Assembled the X-axis actuator.

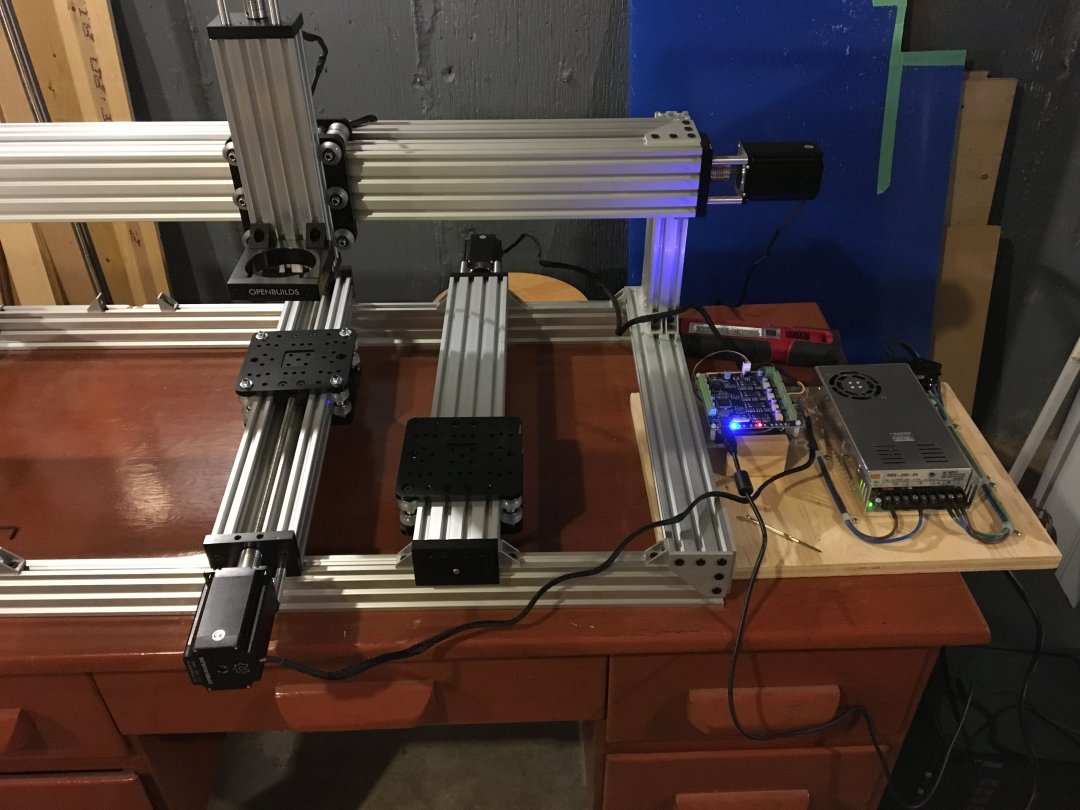

Attached the X-axis.

"Holy"

Y-axes assembly.

Filed off small areas to make space for the lock-collar set-screws.

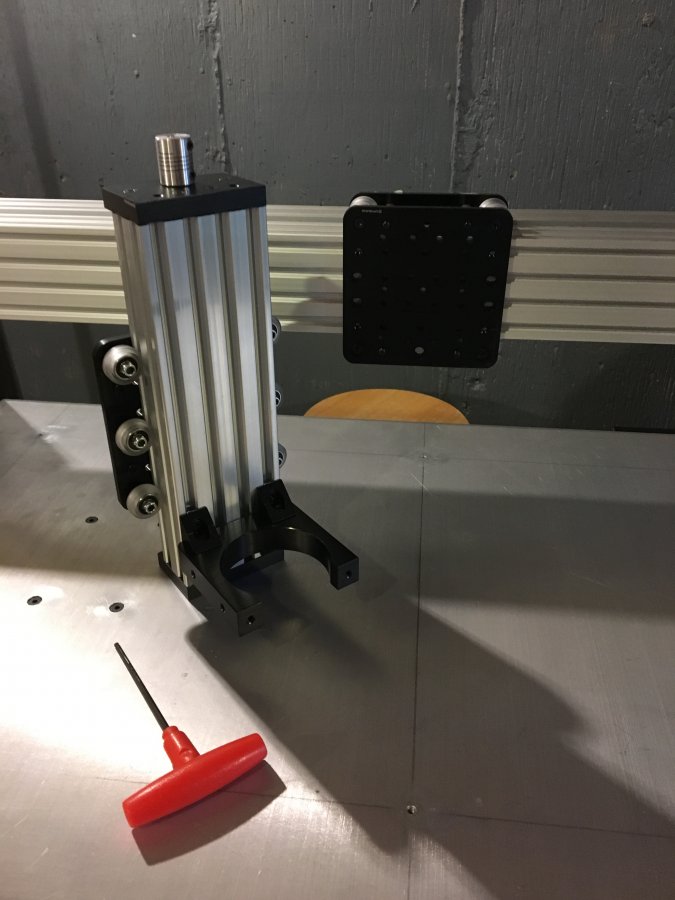

Z-axis happiness:

Nevr-Dull! (and steppers attached)

Wiring time (I really need to buy a new soldiering iron).

But it works.. (on/off switch).

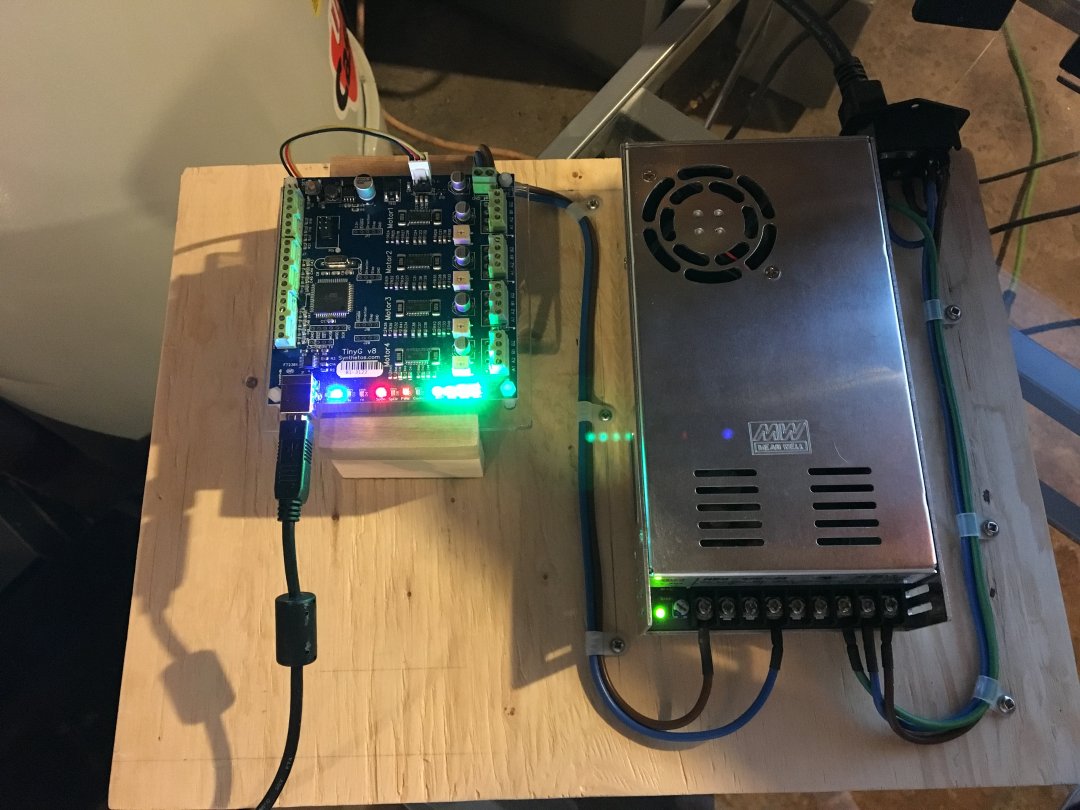

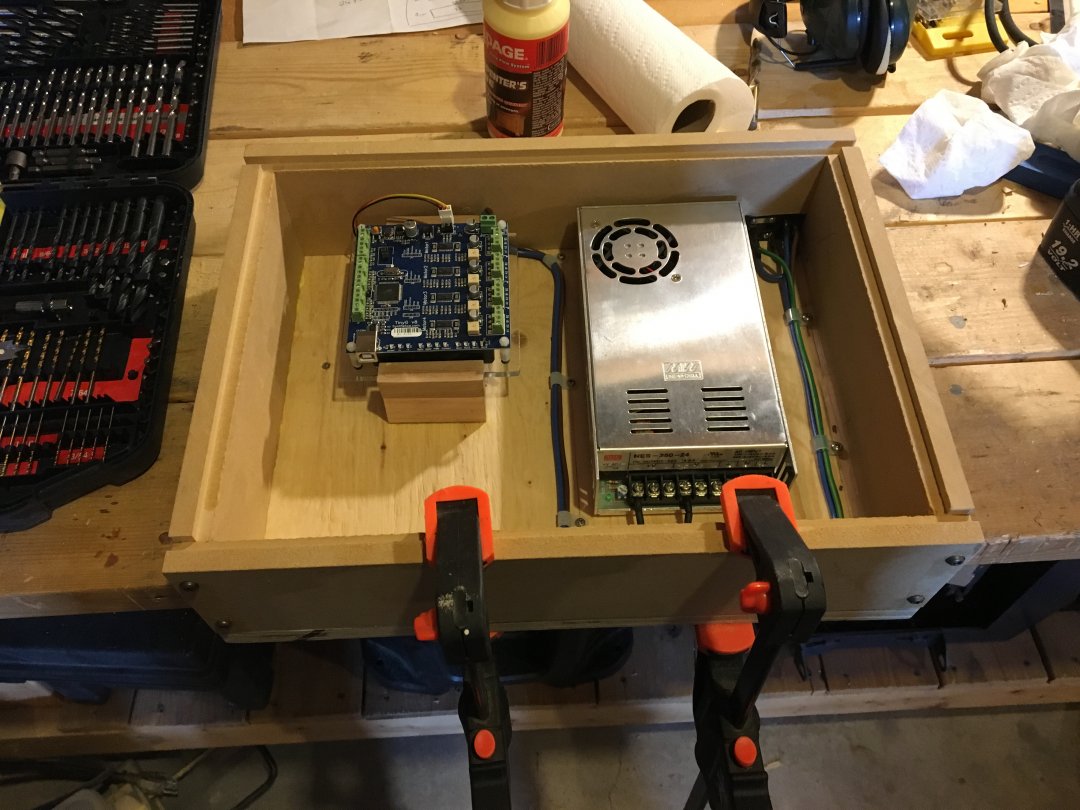

TinyG & 24volt power supply.

No smoke!

After testing the actuators, I had to take each one off and re-adjust the Acme-screw tension. I also used plumber's tape on the inside and outside of each bearing. I wanted to reduce the slop and noises coming from them. This worked very well. I also had to loosen my nut blocks up and reset them snug (without over-tightening them).

The actuators are working much better now!

Video of Y-axes working much better:

Making brackets for limit/homing switches. I could really use a drill-press...

After installing all of the micro-switches, it was time to build a frame to support the drag-chain.

Installed. I'm not all that happy with having the the z-axis max limit/homing switch where it is.. I may change this.

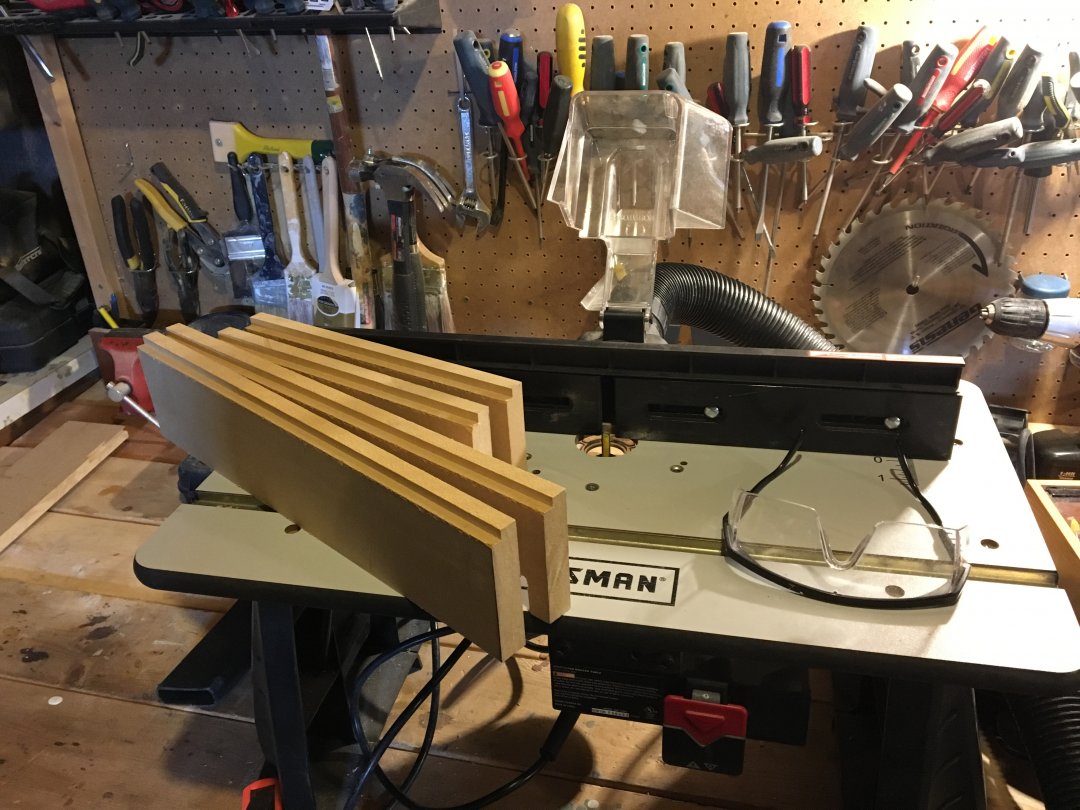

On to the box that will house the electronics. I had some 3/4" MDF so went with that for the sides.

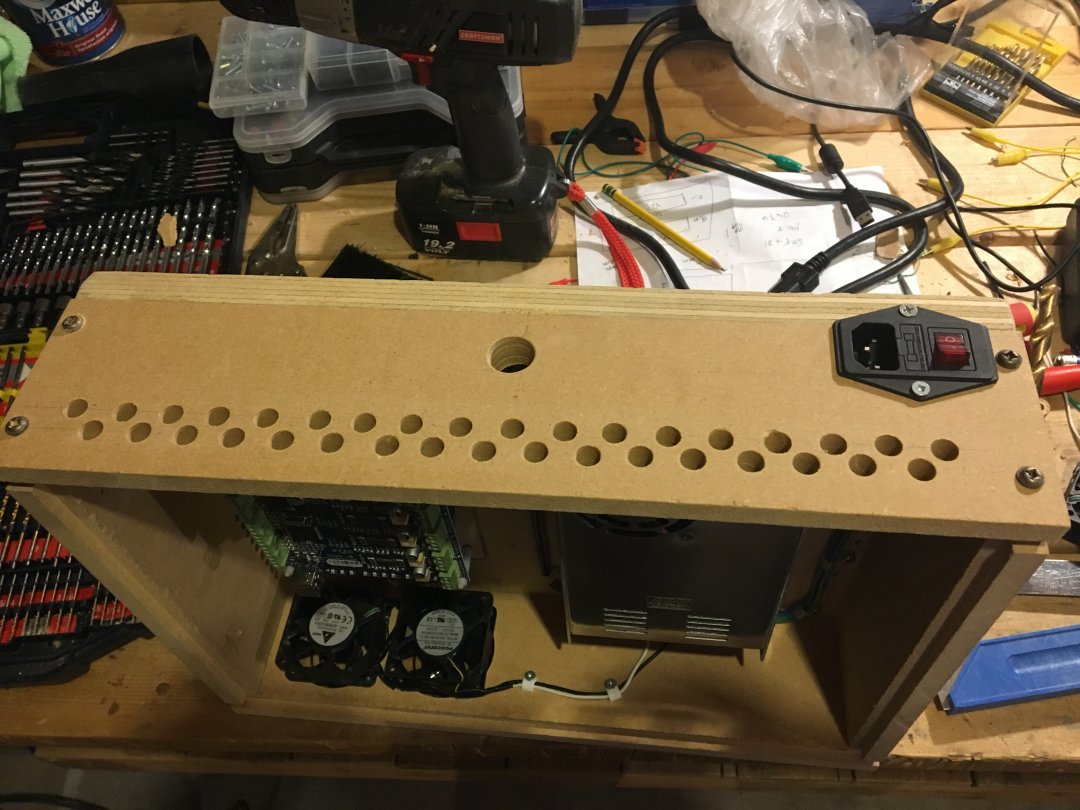

Holes for cables. Through out this build, I kept saying to myself, "Man, I need a drill press. This would be so much easier with a drill press."

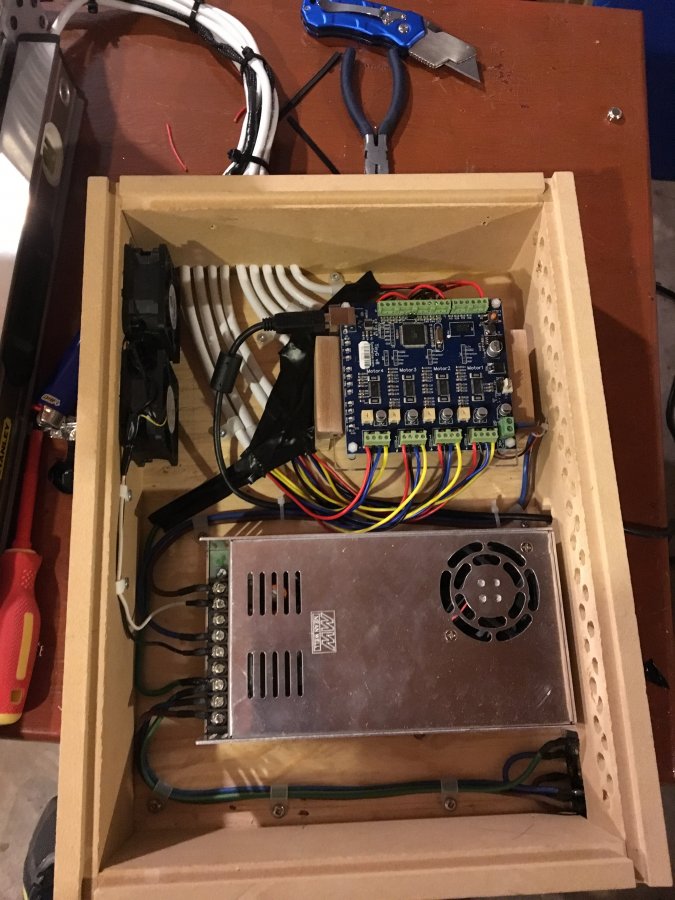

Added some 60mm fans. (there's a 24volt, 80mm fan under the TinyG board as well).

Acrylic always makes everything look nicer (6mm).

Vents... Another drill-press worthy task! (I was pleased how this turned out considering it was done with a cordless drill).

Wiring.

Oooooo:

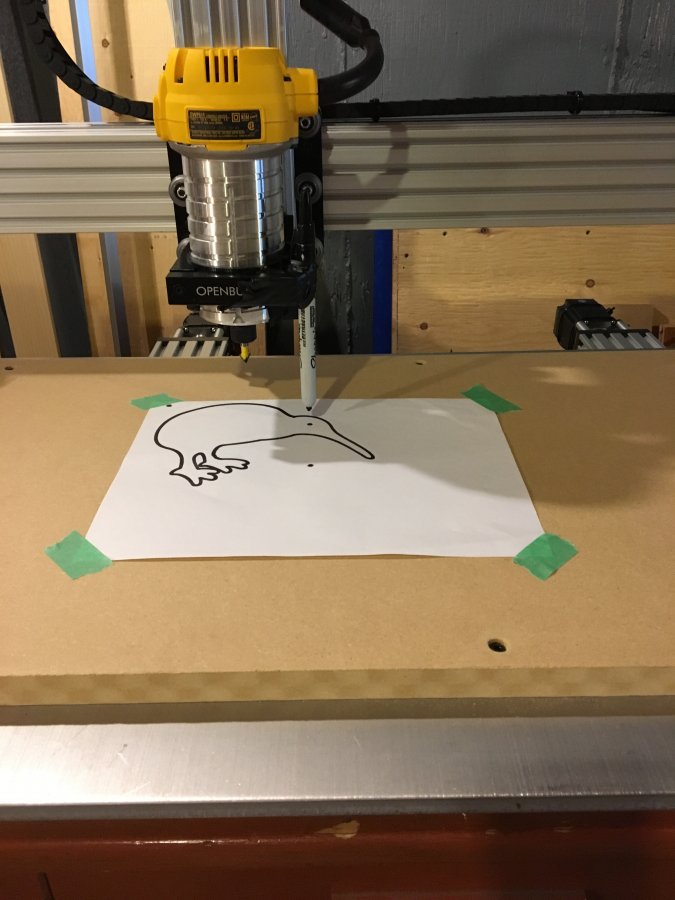

It's router time! @kylesmth was kind enough to 3D print a shim for me. It brought the mount's opening from 71mm to 69.25mm. After a little sanding, it all fit together very well. Thanks to @Jimmybuckets for the shim design (Router Mount Shim 69mm to 71mm ( 0penBuilds Colt to Dewalt Mount ) by JimmyBuckets)

Looking sharp! The spoiler board was made from some 3/4" MDF that I had on hand. I plan on making a new 1/2" one down the road. I also need to set up some kind of clamping system as well.

Testing.

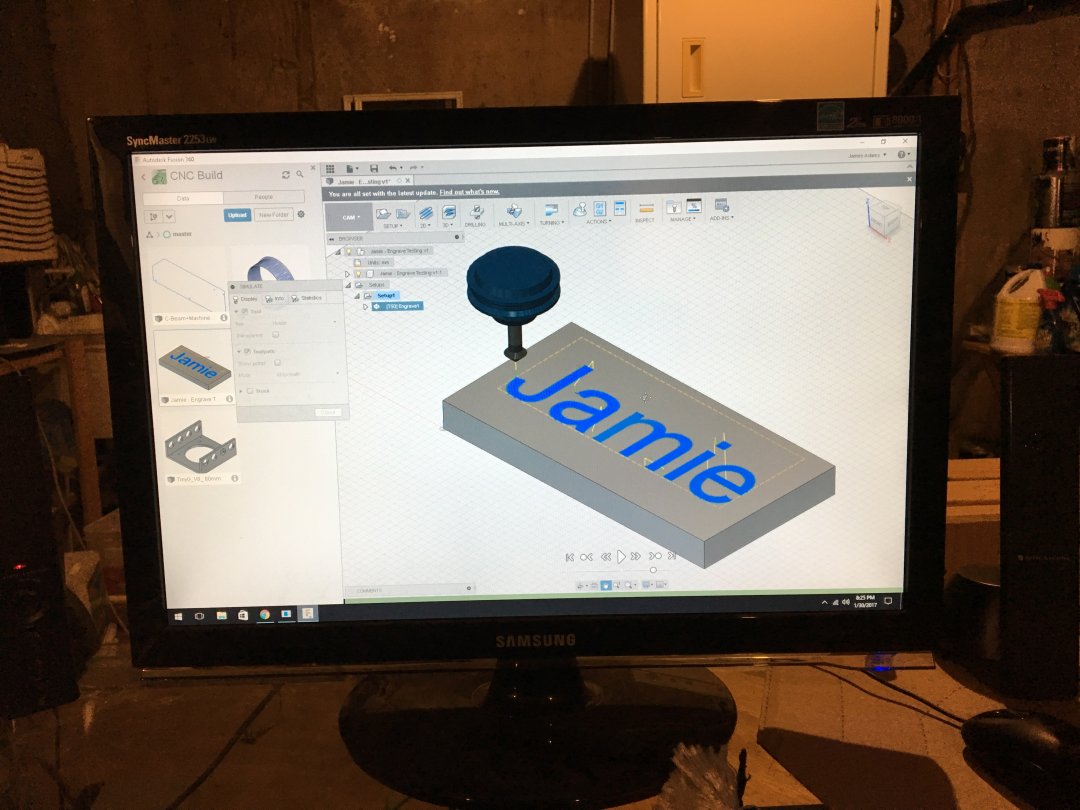

Time for a test cut! The tricky part here is learning TinyG, GCode, Chillipepper and Fusion 360 simultaneously.

Update December 11th, 2017:

After a move and setting up a new wood shop, I plan on getting back to improving my machine. This past weekend, I decided to make some table saw push sticks. I used CNCJS to send the gcode this time and had much better results.

Here is a short video showing some of the cutting.

Also, here is an older testing video for those that are interested.

Cheers. - Jamie

C-Beam XL - TinyG - Aluminium Plate - Dewalt 611

Build in 'X/Y Table Style CNC Mill' published by jamesdjadams, Dec 11, 2017.

C-Beam XL build using TinyG V8.

-

-

-

- Build Progress:

-

- Build Complete!

Attached Files:

-

Special Notes

I will be updating the progress on here while drinking a cold one. Please excuse any non-sense.

Brian Knight, Nikola Stojanovic, Morb and 16 others like this. -

-

Build Author jamesdjadams, Find all builds by jamesdjadams

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution Share Alike - CC BY SA

Reason for this Build

I'm building this so that I can make a number of projects that I have in mind.Inspired by

Moag's "C-Beam Machine XLarge" and Glenn Weston's "The Moagie Mill My C-Beam XLarge"

![[IMG]](proxy.php?image=https%3A%2F%2Fi.imgur.com%2Fer3Yp8k.png&hash=bc406f3dea1047d3f43f6ce3dbaae803)