All metal Ox hybrid CNC Router Table

Discussion in 'CNC Mills/Routers' started by Denis Lapratte, Feb 18, 2018.

All metal Ox hybrid CNC Router Table

Discussion in 'CNC Mills/Routers' started by Denis Lapratte, Feb 18, 2018.

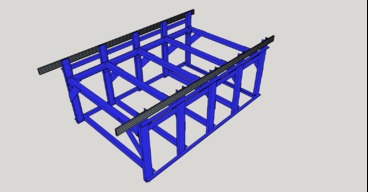

This is my second CNC build, but the first one that I design from the ground up. The base is all metal because I want to add Plasma facility later on. I used the Ox model for the gantry plates and made a few changes to adapt to my design. Since I wanted to use parts from my first CNC to save as much as possible, I kept the 5/8 Hi-Lead Screw I had from Roton for the Y and Z axis. I will also add a downdraft table to keep all parts tight on the table for cutting.