Build List

-

Active Filters:

cnc

Build Author

Mark Carew

Views

48163

Build Author

Mark Carew

Views

48163

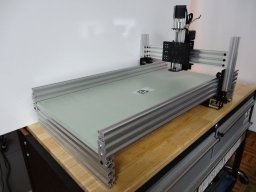

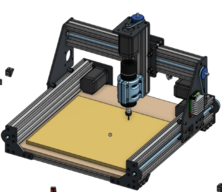

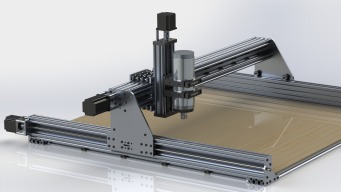

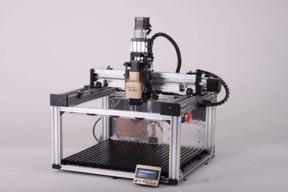

OpenBuilds Sphinx 55 (20" x 20")

The OpenBuilds Sphinx 55 - 500x500 Lead Screw Machine

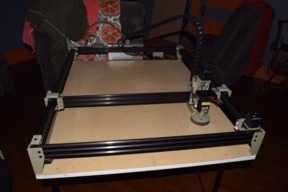

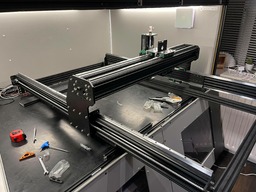

(Smaug) 100w 1500x1000mm CNC Laser

Laser CNC made with mostly Openbuilds and amazon sourced components. Lots of 3d printed components as well. The main purpose is to cut EVA foam.

Build Author

Superslinky

Views

8712

Build Author

Superslinky

Views

8712

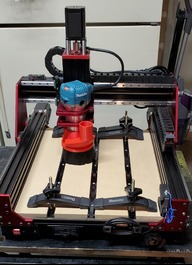

K40 Laser Build (Major Changes)

Major K40 Laser Mod

Build Author

theracermark

Views

3026

Build Author

theracermark

Views

3026

Reviving the Origonal PhlatPrinter with BlackBox

Reworked PhlatPrinter Gen1 Adding dual nema 17s to all 3 axis Supprot for carriage to insure even dept cuts Lighting for view of cutting area

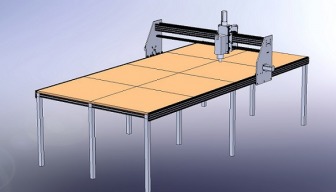

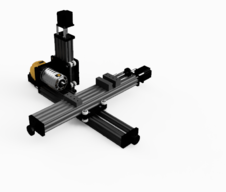

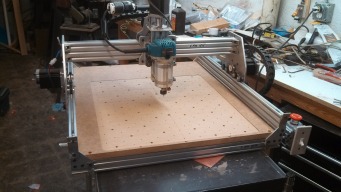

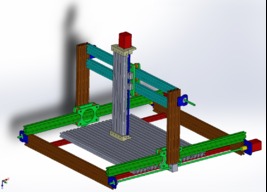

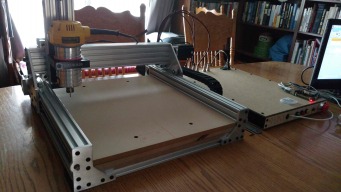

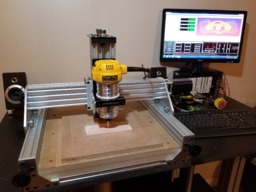

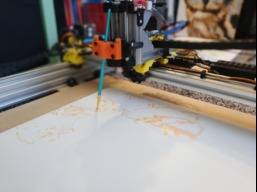

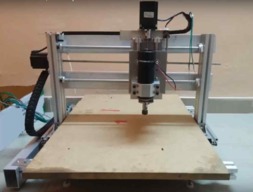

Homemade CNC Router (Under $400)

So Instead of buying a CNC Router which can cost thousands of dollars I ventured on the quest to design and build my own. I have multiple parts to this series. Hopefully all of my information I share helps!

Build Author

Wes Dwight

Views

6161

Build Author

Wes Dwight

Views

6161

Modified Sphinx 55 with MGN12 linear rails

Inspired by previous Sphinx builds by Sorin (w/ MGN Rails) and Kenneth's witthuhnCNC XKLBR-1S. I wanted to create a desktop unit that kept a minimal profile and neatly contained the PS, Controller, and all wiring, making it a singular unit that could be easily transportable (as it will be doing double duty at my home and at work)

Custom push cart for CNC machines

I’m custom building a push table / cart for my cnc machines mostly out things I already had in my garage. Using a gray push utility cart as the main body and building around that.

Build Author

ckgottabuild

Views

2814

Build Author

ckgottabuild

Views

2814

Lead CNC 1010 Platform and Rotating Laptop Mount

Moveable Lead CNC1010 build with handles on four corners. Everything fits on one sheet of cut out 4x8 plywood

Pro Light 1000 CNC Machining Center Rebuild

Replacing the Pro Light control box with a Open Builds BlackBox.

Build Author

Kyo

Views

139426

Build Author

Kyo

Views

139426

C-beam Sphinx

A strong desktop cnc router that will enable you to make larger aluminium plates without taking up to much room. Simple, strong and opensource ! Build one today..

Gigantesque CNC

This is a upgrade to make a little deeper and a little bigger foot print for cutting. This is a copy of design off Rob Taylor idea for Dbl C Beam setup. The goal though is to design it around a new build with minimal tools for some one with no cnc access. Drillpress and drill bits and tap set. A 10in Non ferrous metal cutting blade for my table saw. Paper printer for printing DXF files.

Workbee with less irritations

My workbee build with some add ons

Build Author

Stokrotka74

Views

5785

Build Author

Stokrotka74

Views

5785

Racoon CNC

This is a Sphinx variation, aimed to minimize footprint and maximize workarea. Work in progress.

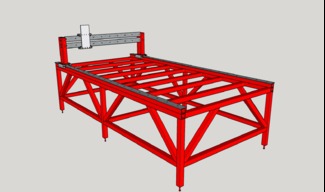

3000x1500 CNC

Here is my Project A CNC 3000 mm by 1500 mm, with a 2.2kW spindle collet ER25 and 4 stepper motor nema 23 425oz-in. The purpose being to have a large work surface for a minimum cost.

Build Author

RSch

Views

3318

Build Author

RSch

Views

3318

Scroll-saw Spiral Cutter

Attached to a scroll saw you can cut nested wooden spirals with this jig. Make two, three, four ... interlocking spirals that unwind/unscrew. Fascinating toys or art objects!

Build Author

CNCGear

Views

8742

Build Author

CNCGear

Views

8742

The BlackBee CNC

Ball screw drive, linear rail CNC Kit

Build Author

Mark Carew

Views

19940

Build Author

Mark Carew

Views

19940

C-Beam® XLarge Linear Actuator

This OpenBuilds C-Beam XL actuator is the backbone of a lot of the awesome builds put together by the OpenBuilds community

Build Author

C-CNC

Views

12642

Build Author

C-CNC

Views

12642

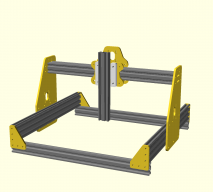

Gantry Style CNC from plywood

I am currently 15 years old, from Germany and trying to build a low budged CNC router. I only designed this CNC based on other CNC routers that I have seen and what I am able of. It consists mostly of 2.3cm plywood to keep costs down. The size of the work area is approx. 40 x 80 cm. I would be really glad if you could give me advice's for improvement on the design and everything else ... ( I could really need your help :) ) enjoy :)

Sea-OX

This is my first CNC build. The Sea-OX is a machine built out of three 1000mm C-Beams. I plan to have a Y length of 1000mm and a X length of 650mm. The Z should have the ability to move approximately 100mm.

first CNC build

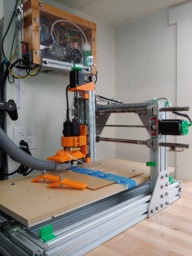

It start out to be an upgrade of a CNC 3018-PRO but ended up being a full build

Plastic Monstrosity

Large inexpensive build that can cut a 4x8 ft sheet with room to spare. Can be built using only a 3D printer and standard parts -- no special CNC'd plates required.

The dwarf

This is a build for those of us that want to work fairly large but are in a tight space and budget

Build Author

Rob Taylor

Views

9100

Build Author

Rob Taylor

Views

9100

Grizzly G0758 Benchtop Mill Conversion

A proper CNC mill conversion. But quite small, with my trademark idiosyncracies.

Retractable WorkBee1510 with Marlin+MarlinPanel high level build

WorkBee1510 with retractable space saving stand and customize build Marlin firmware and MarlinPanel (GCode Sender/UI)

CO2 laser

http://www.buildlog.net/sm_laser/drawings.html using this as a baseline.... Going to try and use all or most off the shelf parts.

Build Author

Vin1027

Views

6184

Build Author

Vin1027

Views

6184

C-Beam Sphinx

This is the original C-Beam Sphinx with the 16 wheel X gantry plates. I'm using the Ethernet Smoothstepper, Gecko G540 stepper driver and Mach 4 for motion control.

Build Author

Joe F

Views

7049

Build Author

Joe F

Views

7049

Rack and Pinion Cartesian Mill

This is a rework of a previous build I did on here, a mostly printed cartesian CNC. Initially intended to just be an update to that, but so many things changed including the linear motion and every single part has been modified significantly that I felt as though it deserved a whole new build.

Ox with Gecko Controller and CNC Linux

This build is the documentation of someone with no experience building the OX cnc machine with a Gecko G540 controller and CNClinux

Build Author

Jacob Lotter

Views

22359

Build Author

Jacob Lotter

Views

22359

1510 Workbee Modified

Some of the things that I have done to my 1510 Workbee Installed Linear rails and bearing blocks with drawings. Installed Ops console Made conversion plates for extruded aluminum to casters Extended z axis travel by a couple inches with steel plates. As of now in the process of installing Lead screws across the 1500mm length.

CNC China Router Conversion to Open Builds System

China Router frame with linear bolts, Nema23 and the icing on the cake “open build parts“

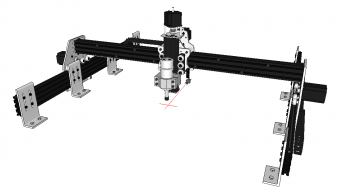

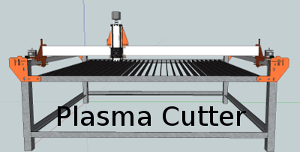

CNC Plasma Table 006

Inexpensive plasma table. Accurate, fast, and low maintenance.

Build Author

sebf34

Views

30555

Build Author

sebf34

Views

30555

OX Based cnc 3000 x 1500 Double belt

OX Based CNC

LEAD CNC 1010 Laser Modification

Easy All-in-One Laser and Mounting Kit for your Openbuilds CNC.

My build

I am satisfied with my build and next one will be even better.

Voxel Evolution

This is a remix of Marshal Peck's Voxel OX, with some design tweaks inspired by Makerparts and jjcolletta. It has a build area of 300mm X 300mm X 480mm, but is easily configured for just about any build area up to 500mm X 500mm X 750mm. I have used some laser cut acrylic plates and a couple of 3D printed parts in its construction, however it can be assembled using nothing but OpenBuilds parts with the exception of the heated bed and the Y axis carrier for the heated bed.

Horizontal CNC V-Beem v1

V-Beem horizontal milling machine built on OpenBuilds components. Simple structure, great expansion possibilities, high stiffness.

Mini-OX

An OX-inspired mini desktop mill. Designed in OpenSCAD, these parts are fully parametric and can be customized to your liking.

Build Author

kallibaba

Views

32081

Build Author

kallibaba

Views

32081

CNC Sand and Spraycalk drawmaschine

A little CNC Sand and Spraycalk drawmaschine More and details in the next weeks

Charging Ox CNC Machine

A heavily modified Ox CNC build to replace SO2.

Build Author

Crazzy French Dude

Views

3896

Build Author

Crazzy French Dude

Views

3896

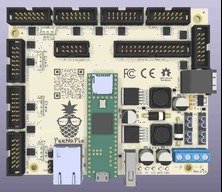

PeeNaPle_V1.4b

PeeNaPle_V1.4b is a BoB controller board for 3D Printers, CnC and cartesian machine, using the latest Teensy_4.1

Build Author

Apothus

Views

21072

Build Author

Apothus

Views

21072

Sphinx rigid XL

Rigid variant of the C-Beam sphinx platform

Massive Hotwire Foam Cutter

CNC Hot Wire Foam Cutter. Lathe, Turntable and 4 axis Cutter. Can cut XPS and EPS.

SCoreXY

Currently I have Velleman/3Drag K8200 modified and CNC machine self built and wanted to use both to make new 3D printer. After looking at different designs I liked Voron a lot and have decided to go that way. Currently I have ordered majority of parts and build shall start soon. I don't plan to rush it as I am usually 2 months home and 2 off. Today done some electronics. Looks ok. https://youtu.be/ls_tl54ruE0

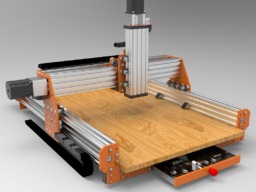

INDY-TR12 CNC (12mm Diameter Lead Screws)

TR12x3 screws, M8 wheel sets, a draw built into the design, an electronics set built onto the kit, back brace to stop C-Beam twist.

Learning how to build

I made a 5x10 foot cnc out of the parts I bought on this site. It's been upgraded and tinkered with ever since. The end goal is to learn enough to learn to build a large 10x10 foot 3d printer.

Build Author

GinoTheCop

Views

13485

Build Author

GinoTheCop

Views

13485

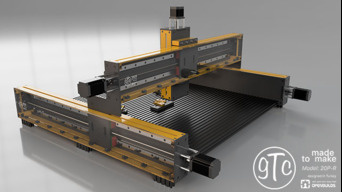

GTC2020

A 1000 by 1000 CNC Router with linear rails and a control box.

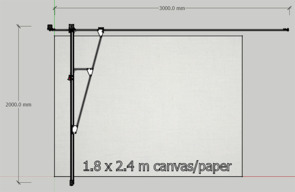

SB Plotter

Large floor or wall mounted plotter design.

My Ooznest Workbee V2.0 build

I'm new to this whole process, so this is a build by a newbie for newbies.

Build Author

Andreas Bockert

Views

10580

Build Author

Andreas Bockert

Views

10580

Sphinx Z-axis upgrade

Upgraded Z-axis for Sphinx-style CNC using ball screws and linear rails.

Build Author

Schematix

Views

152925

Build Author

Schematix

Views

152925

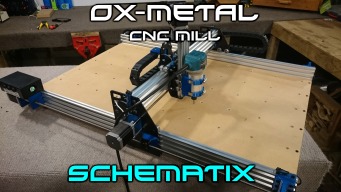

OX-Metal CNC Router Mill

The OX-Metal is based on the original OX CNC mill But with a few modifications and add-ons

Plasma CNC machine

The plasma CNC that I have built has a water table that measures 1350mm x 650mm. The water is flooded onto the cut area while cutting and recycled around with a pump. This is to reduce smoke, cool the metal being cut to reduce distortion and also to keep sparks to a minimum. Most of the machine has been made from aluminium , the frame and table from steel, the water table, stainless steel.

Cnc Router 3000 x 1000 mm

In progress

1200X600 SPHINX

Need cnc to make alumunium sign, brass stamp, etc

Build Author

beardyblair

Views

24221

Build Author

beardyblair

Views

24221

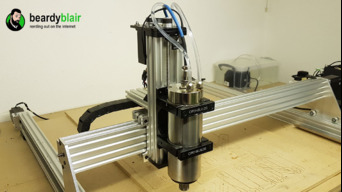

Sphinx XL

My build log of an adapted Sphinx design with additional height and a larger X and Y axis.

Plasma cutter - 608 on steel tube version

CNC Plasma cutter: 608ZZ on steel square tube linear rollers Welded frame HDT2-15 Belt Drive Tradeweld Cut-40 Plasma cutter with converted hand torch Virtual Torch Height Control through inductive probing - open source electronics project

Build Author

Tristen Poliseno

Views

2254

Build Author

Tristen Poliseno

Views

2254

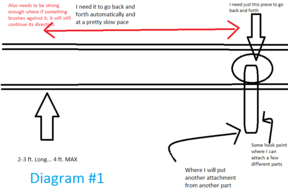

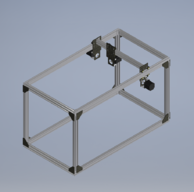

Back and forth rail mechanism

I have the whole description and all the details in the "Body" section!

WorkBee Saving Lives

Using the WorkBee to protect doctors against Corona virus.

Build Author

Braden Masse

Views

2614

Build Author

Braden Masse

Views

2614

Microwave Filter Tuner

The Microwave Filter Tuner (MFT) combined with the University of Regina’s tuning algorithm automatically tunes microwave filters by using a custom CNC machine with a computer vision system for identifying, mapping, and tuning each filter element, providing improved consistency, flexibility, and accuracy compared to traditional methods. The MFT is low cost and is capable of tuning multiple filter configurations with minimal preparation.

Build Author

Alexander Leiser

Views

13798

Build Author

Alexander Leiser

Views

13798

Paintbot painting cnc

Custom painting machine in designed and wrote the software for. Paintings are with acrylic color on canvas

Build Author

SandeepsCNC

Views

10767

Build Author

SandeepsCNC

Views

10767

Raspberry Pi CNC Software

The main objective is to build a software which can completely run on a single board computer, Rasbperry Pi, to reduce the complete cost of building a cnc machine. The software is extensively tested and can be run on any raspberry pi 2/3 boards. With no G-Code dependency, you can do complex 3D relief carving to simple tasks with simple GUI based project development environment. Please go through the YouTube channel for more details https://youtu.be/8KOXqLpvscg

Aluminum OX build with some modifications

This is my OX CNC router. It has been a labor of love for over a year now! I hope you find it interesting and inspiring! I also hope that it gives some of you more experienced CNC builders a different perspective and some ideas!

ROUTY CNC Router (V-Slot Belt & Pinion)

A cool little CNC router build that uses the V-Slot belt & pinion drive and stock parts.

Yet Another LEAD CNC Build

My take on the LEAD CNC build. Followed the instructions and I think it came together very nicely. Added a few of my own touches to finish up the build.

Build Author

Mark Carew

Views

6759

Build Author

Mark Carew

Views

6759

OpenBuilds PowerCase

A simple to assemble, super clean and safe PSU case solution that fits into the OpenBuilds wire management ecosystem

SharkBits Holder

Get organized with the SharkBits Holder!

OX TWO in ONE

What I'm doing is pretty self explanatory. I've put a few pictures up

Ox cnc improvements chain driven

Just ox cnc experiment

Build Author

DaleShaw

Views

3521

Build Author

DaleShaw

Views

3521

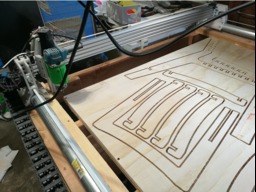

Senior Project CNC table

So for my senior project I decided to build a CNC router. I kind of need to get this done before May so we'll see what all goes down. It's going to be a 3 axis machine (for now) and will be able to handle 4x8 sheets of wood. This is my first build. It's going to be intresting..

Build Author

David Florian

Views

8734

Build Author

David Florian

Views

8734

Dual Extruders 3D Printer - Zidex Upgraded

How to build an Independent Dual EXtruder (IDEX) 3D printer from OpenBuilds parts.

Build Author

Darren Dickson

Views

3218

Build Author

Darren Dickson

Views

3218

3D printed CNC Machine

So I thought I would make the Leon van den Beukel version three 3D printed CNC Machine, it is the third incarnation so you would expect a relatively bug-free CNC Machine with a strong foundation.

Build Author

Neil Scott

Views

2129

Build Author

Neil Scott

Views

2129

Barcelona Build

This will be my second CNC build but this time a proper CNC not a small desktop model that I played with for a while to learn Gcode, It was great but now its time to start playing with the big boys and girls.

Build Author

mytechno3d

Views

34040

Build Author

mytechno3d

Views

34040

Plasma cutting table

This is our plasma cutting table , based on the famous OX CNC . Can cut up to 15 mm ( steel , stainless , aluminium ) with a really good accuracy and at a really high speed .

Build Author

Mark Carew

Views

29533

Build Author

Mark Carew

Views

29533

OpenBuilds Sphinx 1050 (20" x 40")

The OpenBuilds Sphinx 1050 - 500x1000 Lead Screw Machine

PhlatMDF48

Building a Phlat based CNC for MDF processing. Capacity of 48" x unlimited length.

Build Author

Vunnie

Views

5873

Build Author

Vunnie

Views

5873

Workbee CNC on steroids

My First major improvement was changing the controller to a Acorn board. I loved the way a dedicated userinterface was speeding up my workflow. Next project my Y Axis. On Aliexpress I ordered a couple of 16mm ballscrews and some lineair rail. Before I took my gantry off I quickly made some aluminium profiles to fit my carriages. Withouth any doubt these improvements where worth it

Sphinx 55 with 3D Printed Addons

This is a build log of the Openbuilds Sphinx 55 with some 3D printed parts for the electronics and probably other parts as they come up.

Build Author

Mark Carew

Views

24731

Build Author

Mark Carew

Views

24731

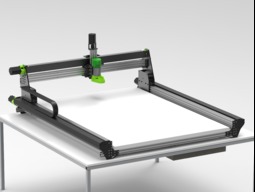

OpenBuilds Workbee 1050 (40" x 20")

The OpenBuilds WorkBee 1050 - 1000x500 Lead Screw Driven CNC Machine

cnc vreesbank 2500x30000

This cnc milling machine is 3 meters by 30 meters,

Build Author

MattR

Views

15121

Build Author

MattR

Views

15121

Fixed Gantry CNC Router with Old Industrial Supplies

I got lucky enough to purchase aluminum extrusions and linear motion components (and nuts/bolts/etc) at scrap metal prices when a bunch of industrial automation equipment was decommissioned. The only problem is that the aluminum extrusions are not metric sizes... they are the 1.5"x3" 80/20 series. It has presented a few challenges but nothing too bad.

Build Author

Craig Hollabaugh

Views

3727

Build Author

Craig Hollabaugh

Views

3727

Hyatt and My Journey to Tonehenge

I'm conducing guitar loudspeaker cabinet fabrication technique research (material type/thickness, mechanical joints, adhesives, etc) and how these relate to cabinet/speaker coupling and enclosure resonance with respect to psycho-acoustics. Basically, does one speaker cab sound better than another and why?

Build Author

mjenkins5720

Views

2040

Build Author

mjenkins5720

Views

2040

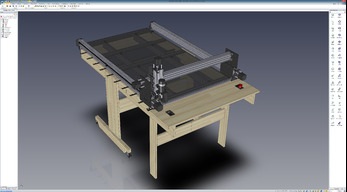

Modified LEAD machine

At the moment this build is in progress, I will be updating the files as I finish the remainder of the machine. This machine is intended to be a multipurpose CNC, but a bit bigger than a desktop unit. The machine is scalable in the X and Y axis.

Cnc od grinder and thread grinder

This is a totally original build of an od id grinder and thread grinder, I hope.

BKE Lead 1010 - First CNC Router

LEAD CNC

Cnc Mill using standard and 3d printed cimponents

I used the cad designs for the c beam to find a solution to my initial sourcing problem. I figured that I could use 2x 20x20 and 1x 20x80 Profil to create a c beam actuator. I sourced all of the profiles from a local machin builder and t-nuts and screws in my local hardware store. Some parts are currently in 3d printed pla for testing reasons.

Build Author

Lasersc

Views

9498

Build Author

Lasersc

Views

9498

D&R Tiger Paw build combo

The Tiger Paw will be a 1000mm X 500mm Cartesian style CNC with the Minimill attached to the end. It is named the D&R Tiger Paw because my son, Daniel, and myself, Richard, will put this Tiger strong and fast machine together. Our goal is to have a Tiger strong build with a Paw print that wouldn’t take up a huge amount of space in our garage.

CNC 1000x1000mm C-beam

inspired by http://openbuilds.org/builds/c-beam-sphinx.3605/

Build Author

viktop

Views

16151

Build Author

viktop

Views

16151

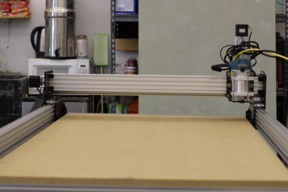

Simple CNC Router (Nema17, V-slot 2040, Arduino, GRBL)

An OX-inspired mini desktop mill.

Build Author

Sir Bagels

Views

2156

Build Author

Sir Bagels

Views

2156

CNC Auto-pipette

Senior Design Project Bennett Robertson, Megan England University of Iowa College of Engineering

Build Author

Lasersc

Views

3910

Build Author

Lasersc

Views

3910

The D & R TigerPaw Trilogy

Hopefully this will be a quick guide to one way that you can add a laser to an existing CNC router.

CNC Router Machine

CNC Router with working area 550*550*200

Build Author

roadss

Views

23191

Build Author

roadss

Views

23191

Rawcnc 1.5 Desktop Edition

This will showcase the build of my Rawcnc 1.5. A rigid cnc router from the Swedish company Rawcnc, featuring a rather cool linear motion system, rack & pinion and steel reinforced X-axis capable of milling aluminum.

Build Author

msdosfx

Views

5182

Build Author

msdosfx

Views

5182

Workbee 1510 Screw Driven

Workbee 1510 screw driven build by MsDosFX.

EOX v2

Upgrading my CNC router to run on ball screws. Me and the belts where not getting along.

Build Author

KronBjorn

Views

3689

Build Author

KronBjorn

Views

3689

WorkBee Lead 1010, Reduced Footprint, Nema17

This is a WorkBee 1000x1000mm with lead screws and Nema17's. It has a reduced footprint, with the geared Nema's inside the frame.

Build Author

RobFromLDMS

Views

4157

Build Author

RobFromLDMS

Views

4157

Lithgow Mens Shed CNC build

The tale of how we put together our CNC Router, and some of the difficulties encountered. It is now ready for final testing and commissioning.

Rotary CNC

I'm building a machine specifically for doing 4th axis work on woodwind instruments.

Phlux Core XY Laser Etcher

A 750mm x 1000mm Core XY Laser Etcher/Cutter. To cut down on cost I tried to have as many parts as possible be printed.

Build Author

John J Talavera

Views

17427

Build Author

John J Talavera

Views

17427

CNC FOR EVERYONE!

This build was very complex due to the fact I wanted to create a low cost larger than normal CNC. I did not want a MDF or plastic body. I wanted it to be able to do more than most CNC routers this size on the market.

Cnc mill, Plasma cutting and weld table

A functional table for plasma cutting, welding, tooling........

Build Author

Mark Carew

Views

32770

Build Author

Mark Carew

Views

32770

PhlatPrinter MK 3

The Phlatprinter 3 was designed to be used in a small shop with the ability to cut large sheets of foam for RC airplane projects. The idea was that you could save all of your aircraft as models and tweak to perfection after every flight.