My Hyatt machine will assist in guitar speaker cabinet fabrication including single and multiple speaker (2, 4, and 6) designs.

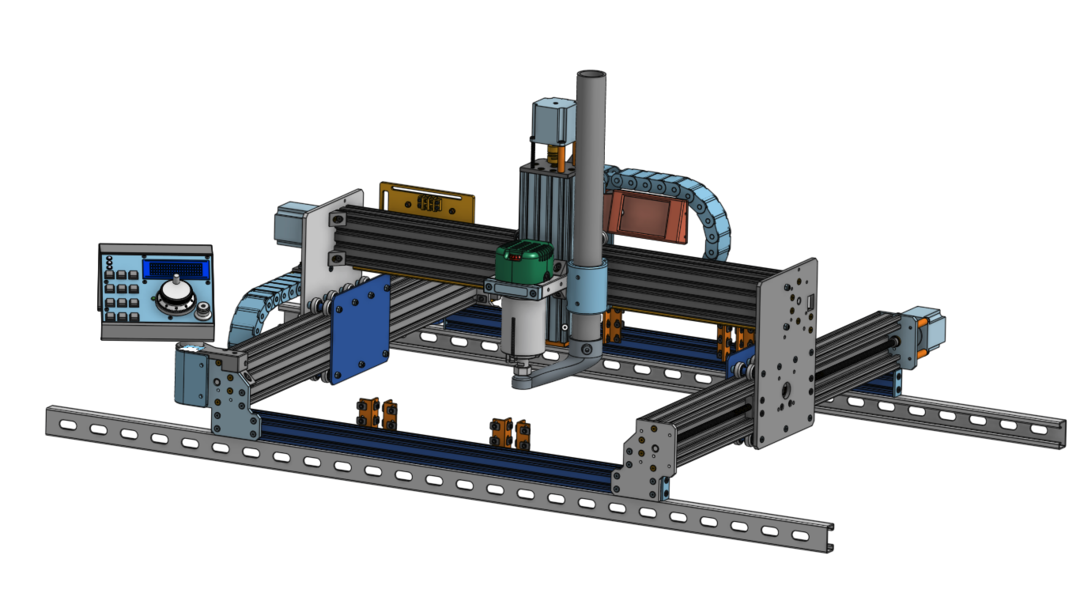

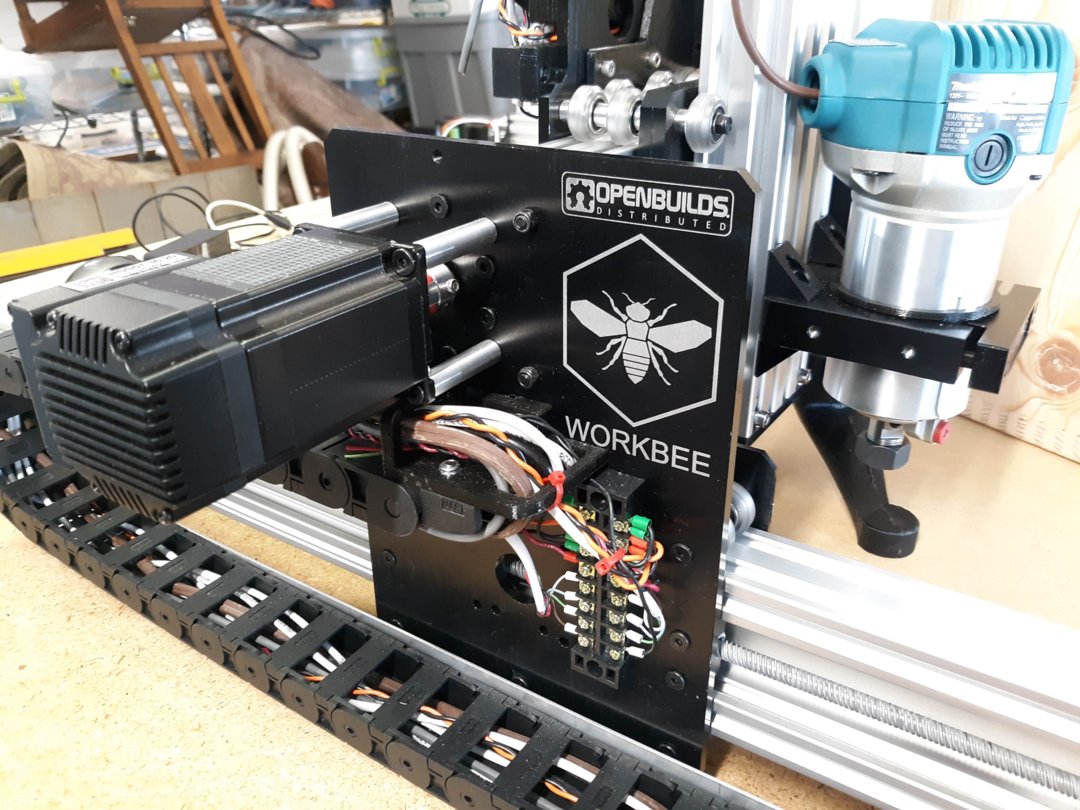

The screw-driven Openbuilds Workbee 1010 was perfect.

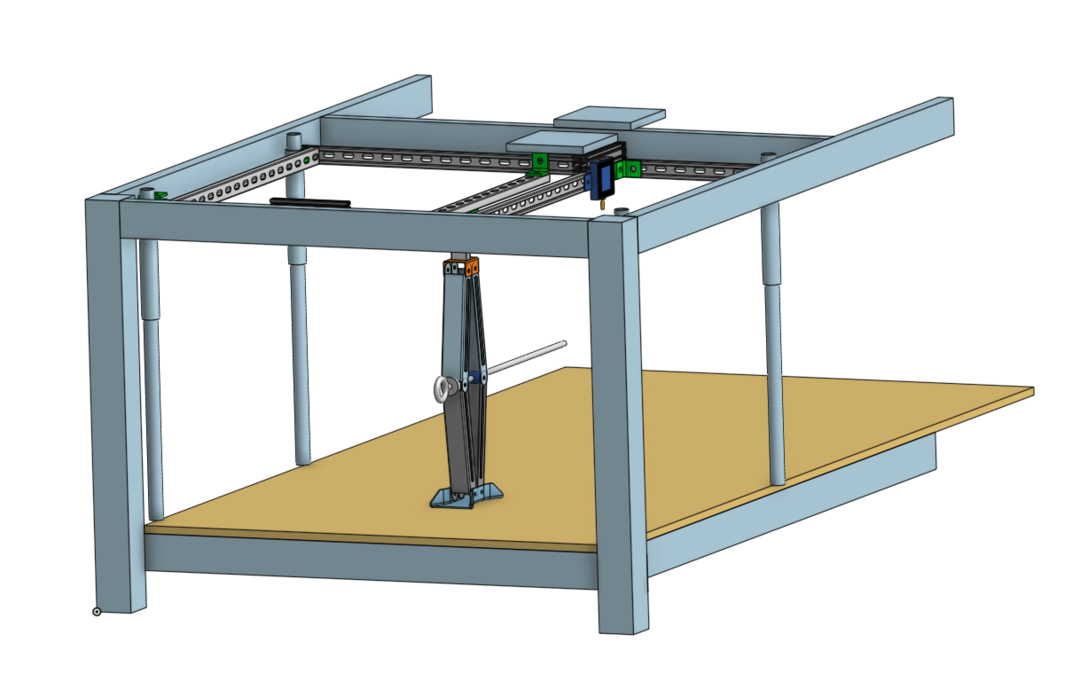

With limited workshop space, Hyatt will store inside my 9'x5' workbench and rise to working height with a mechanical lift system.

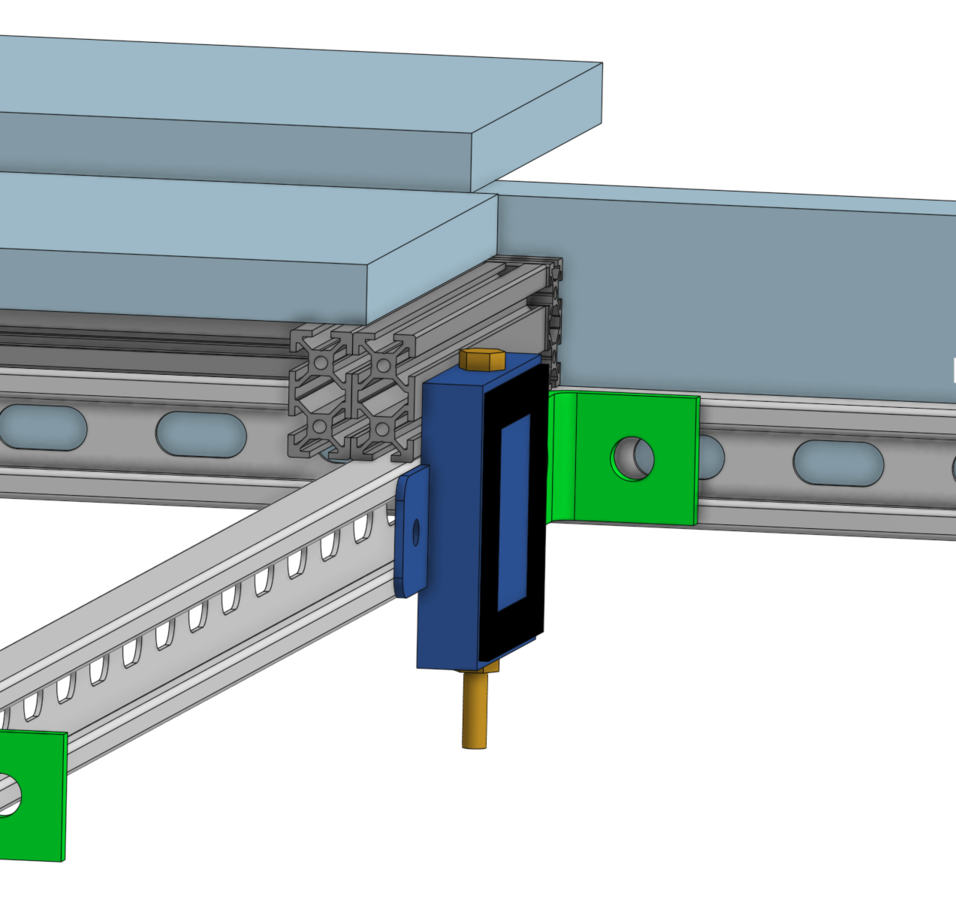

Many speaker cabinet designs use finger joinery. Hyatt has a removal split work surface that enables vertical stock end milling. Using vertically-mounted Rockler Vacuum Clamps, vertical stock protrudes through the Hyatt base for stock-edge finger joint cutting.

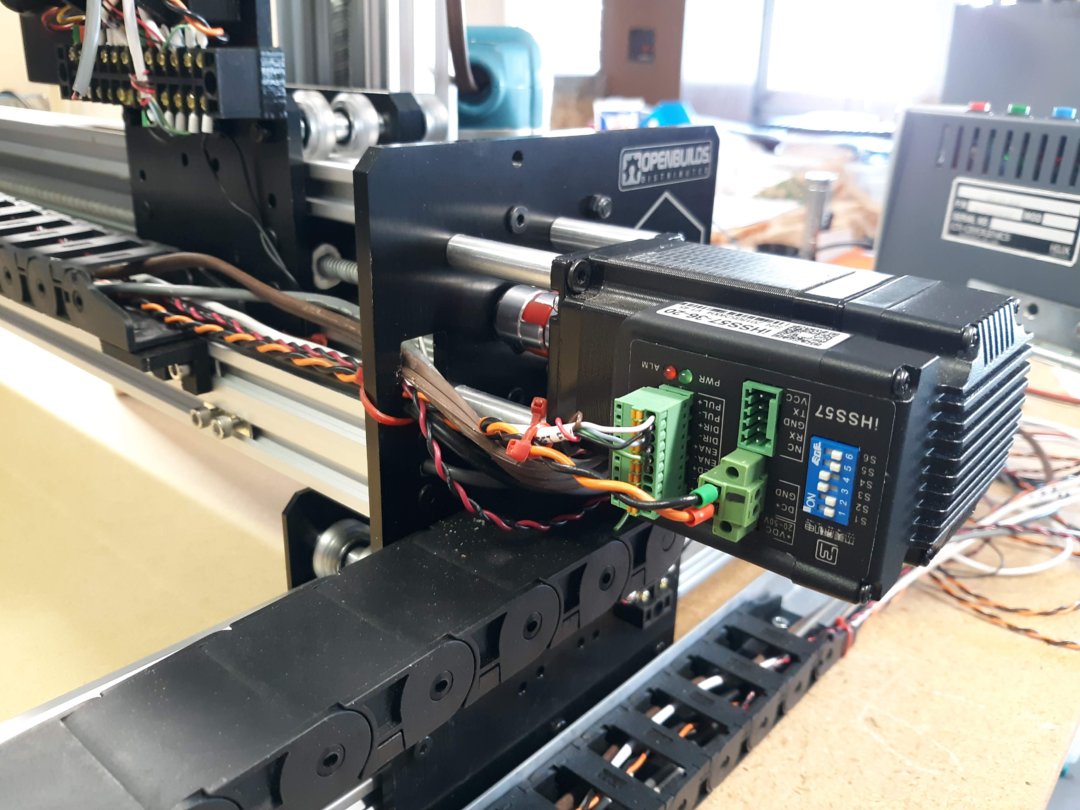

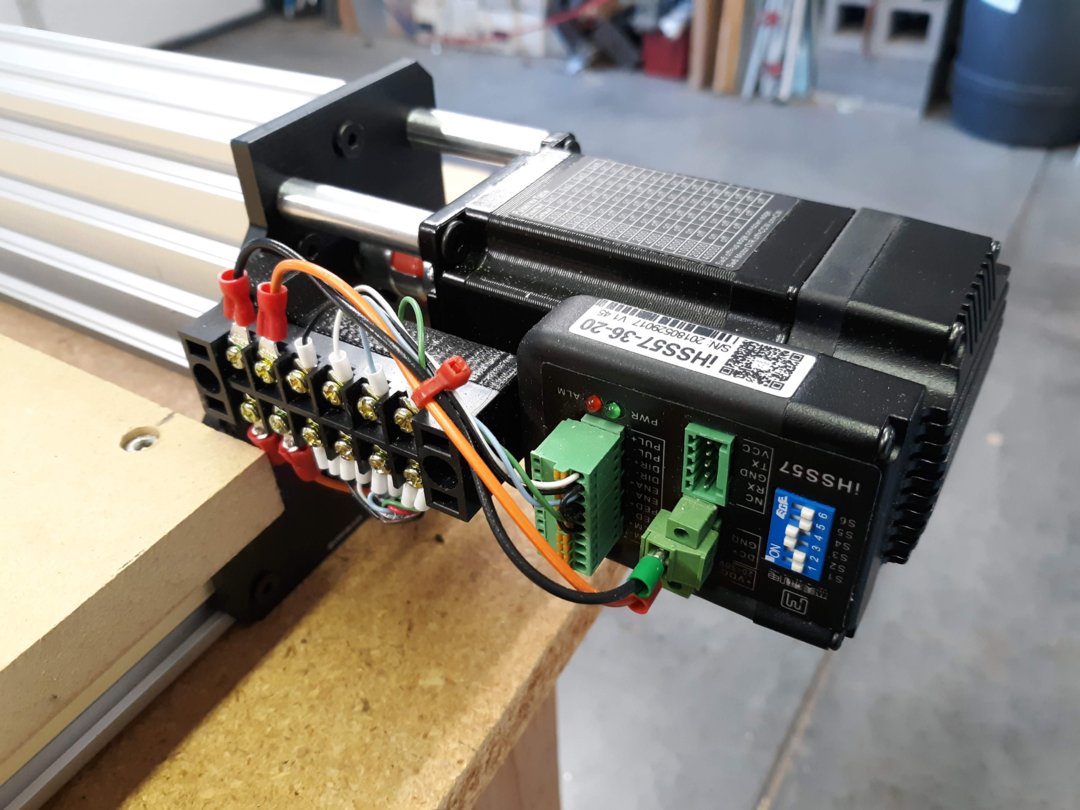

Hyatt steps up motion performance using JMC NEMA23 2NM integrated step-servo motors with driver and position encoder.

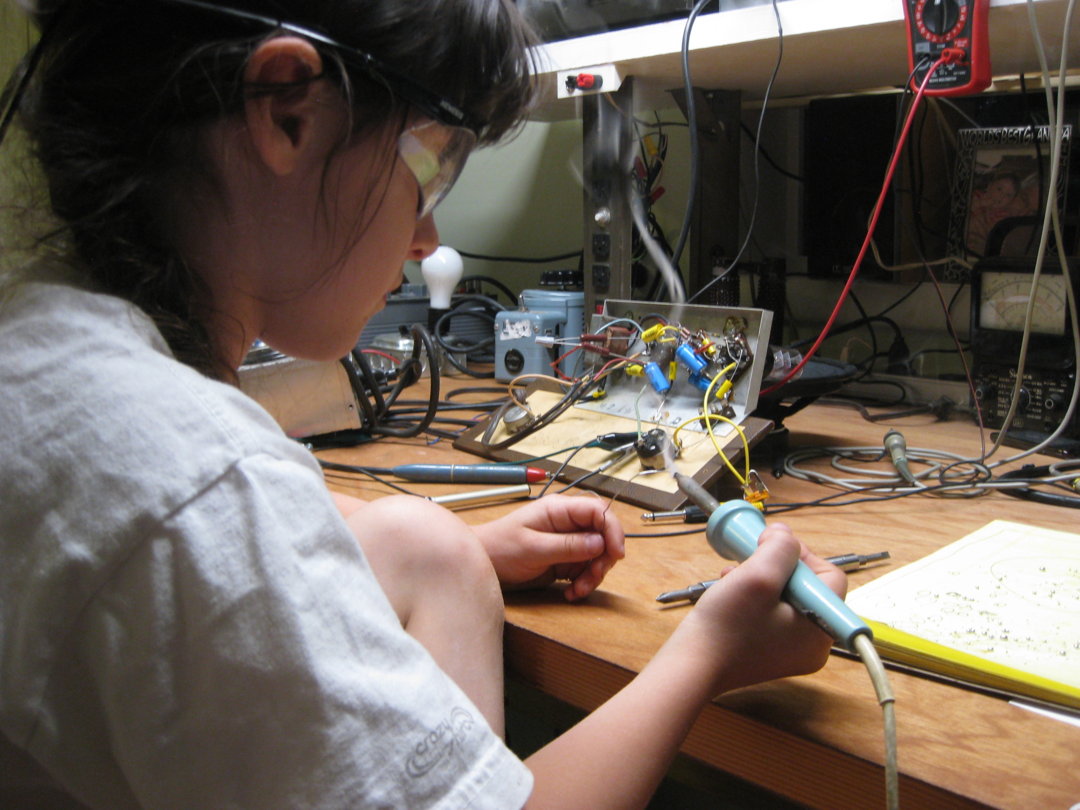

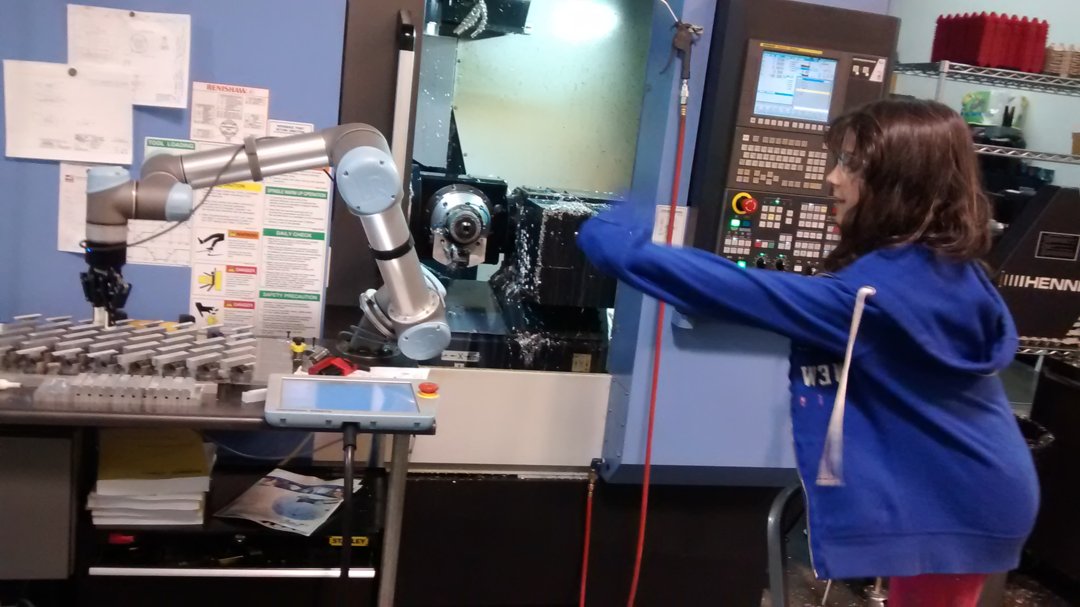

I also wanted a machine that my granddaughter and wife could operate manually (ie no CAD/CAM/Sender). She and I work on various projects together.

A variety of operator interface projects exist, mostly involve a laptop or RPi. I didn't want this for Hyatt. There's too much to know, the operating learning curve is too long. Hyatt must turn on and be ready to run in 5 seconds. Otherwise my now-impatient granddaughter will go back to playing computer games. I want her to experience the joy of precise machining and project builds.

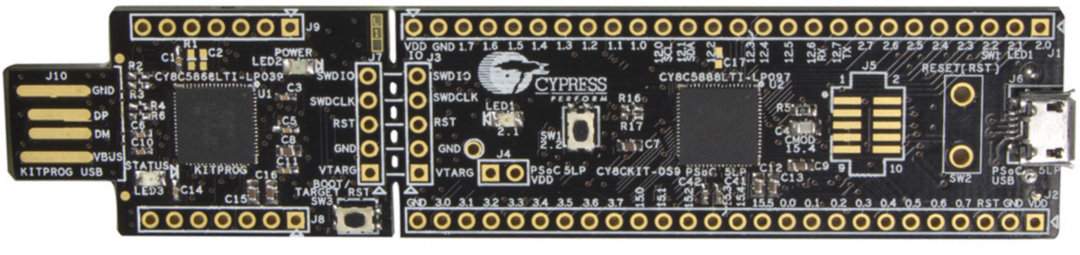

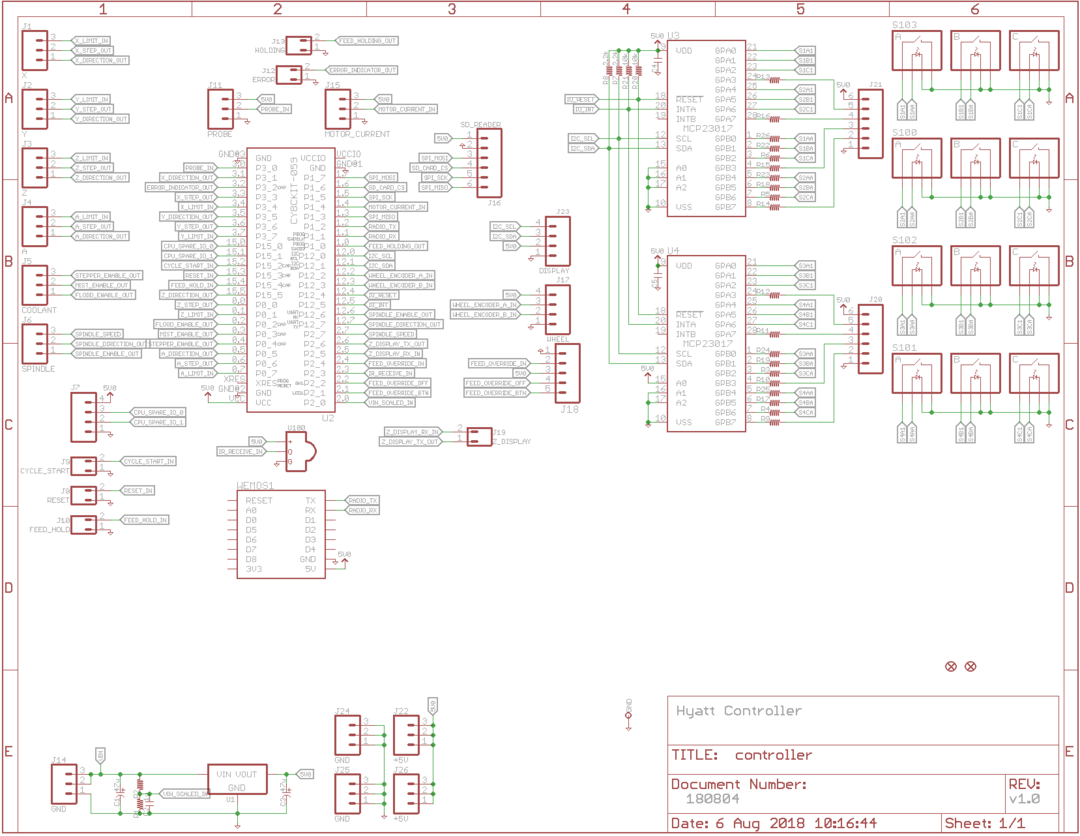

That being said, I set off to create an operator interface and machine control system using Bart Dring's GRBL Cypress PSoC5 port that includes the following.

Hyatt Feature Set

Operator Interface

- CY8KIT-059 based design

- 4 axis CNC controller, Dring GRBL port - PSoC HW pulse generation, debounce, interrupts

- Spindle speed/direction control - PSoC PWM

- Piezo element work piece probe - PSoC opamp, ADC, DAC comparator, interrupt

- Motor drive current monitor - PSoC analog mux and ADC

- Supply voltage monitor - PSoC ADC

- WiFi link with webserver, OTA, flash filesystem, websockets, TCP-serial bridge using ESP8266 - PSoC USART

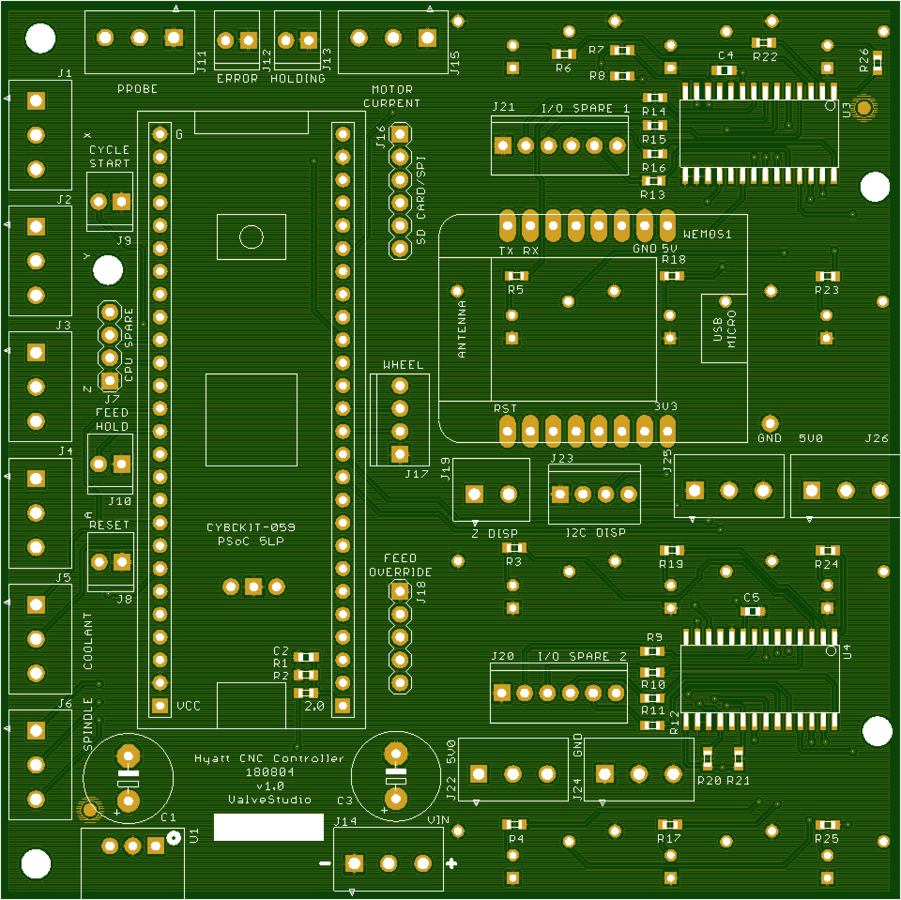

Custom PCB board, 100x100mm 2 layer, mixed through and SMT parts, see holla2040/hyatt

- 12 illuminated buttons via I2C I/O port expanders - PSoC I2C Fixed master

- Jog wheel with quad encoder - PSoC quad decoder

- 20x4 LCD panel display - PSoC I2C Fixed master

- 3.5" TFT 480x320 resistive touch screen display, attached to X axis gantry - PSoC USART

- Real-time feed speed override - PSoC ADC

- SDCard reader- PSoC SPI EmFile library

- Wireless CNC pendant - DirecTV remote control - my custom IR decoder using PSoC digital logic

My complete build progress is documented here, The Valve Studio WorkBee 1010 Build and holla2040/hyatt .

I'm almost done and operational. Step-servo performance is unbelievable with 0.001mm positional accuracy (100x better that I need). See

Project named after Dale Hyatt, the one of the original K&F (Kaufman and Fender) guitar amp cabinet makers. See "The Sound Heard 'Round the World", Richard Smith, p28.

Hyatt and My Journey to Tonehenge

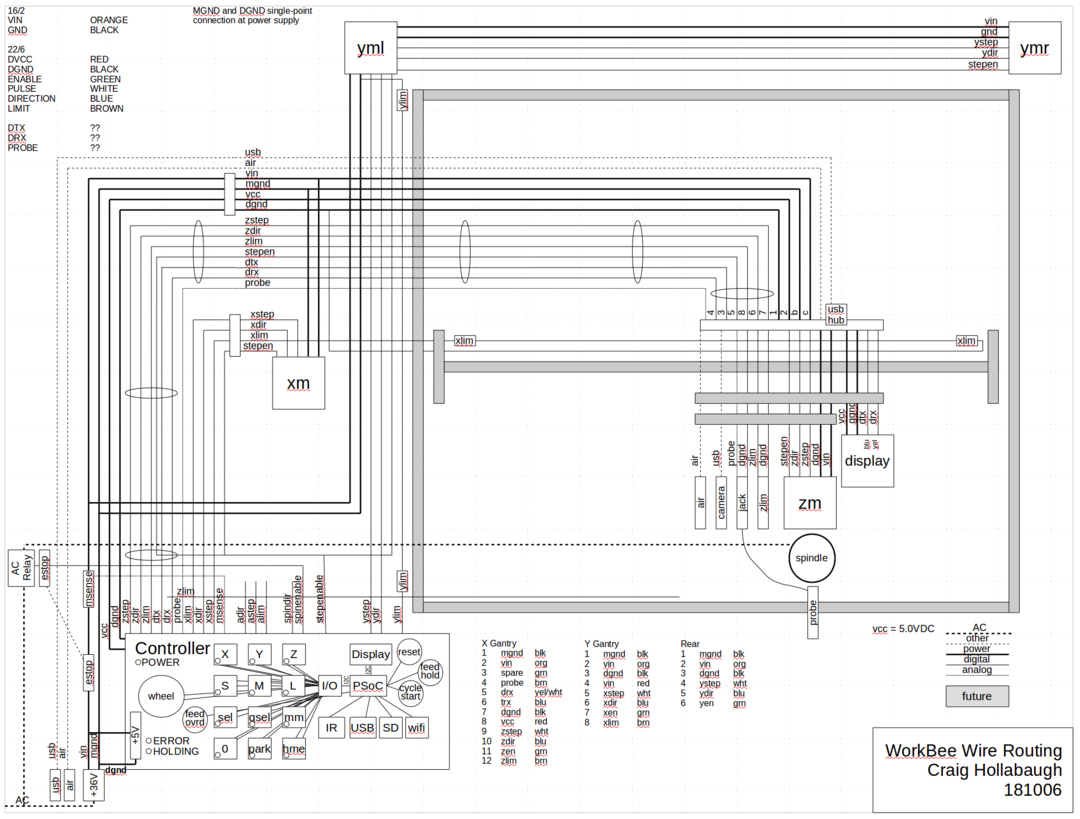

Build in 'Cartesian Style CNC' published by Craig Hollabaugh, Dec 1, 2018.

I'm conducing guitar loudspeaker cabinet fabrication technique research (material type/thickness, mechanical joints, adhesives, etc) and how these relate to cabinet/speaker coupling and enclosure resonance with respect to psycho-acoustics. Basically, does one speaker cab sound better than another and why?

-

-

-

- Build Progress:

-

- Build in Progress...

Attached Files:

-

Special Notes

I love the Hyatt operational simplicity. However that comes with a complexity of design that requires multi-discipline experience. I'm an embedded hardware designer with 25+ experience years, so digging into GRBL, PSoC, and circuit design is what I do.

Hyatt's desired output, guitar speaker cabinets, is part of my true lifelong passion to learn every aspect of guitar amplifier design. This build lasted a year and I loved every minute of it. Its yet another step on my journey to Tonehenge.

.ant, MaryD, Anthony Bolgar and 1 other person like this. -

-

Build Author Craig Hollabaugh, Find all builds by Craig Hollabaugh

-

- Loading...

-

Build Details

- Build License:

-

- MIT Licence (MIT)

Reason for this Build

I need a precise machine to eliminate fabrication variance when researching speaker cabinet design choices. If I'm evaluating tonal differences between cab A, B and C where A,B and C might be different material, thickness, joinery, etc. I don't want introduction of additional variables to due to fabrication differences.Inspired by

Clearly the Openbuild's Workbee build videos. -

Attached Files:

-