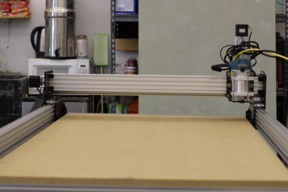

This is my 1500mm x 1000mm screw driven Workbee. I was originally trying to drive it with Arduino and CNC Shield, but I couldn't find complete wiring diagrams anywhere that included the E-Stop, Limit switches, momentary switches, fan etc. So I switched to the current version X-pro controller. I also originally built it with the very shallow depth of cut using the 4x20 vertically oriented V-slot rail, but immediately realized that it was way too shallow to cut anything thicker than some plywood, so I ordered some 2-20 v-slot and improvised the supports under the spoiler board. The Machine is up and moving, and I have performed some air cuts, but I haven't tested it out actually routing material yet. I am still trying to figure out creating my G-code in RhinoCAM and opening it in OpenBuilds Controller. I am using GRBL inch for my post processing in RhinoCAM, but I need to change some settings because I am manually controlling my spindle speed (makita router), and I am not sure how to turn off those settings in RhinoCAM.

Workbee 1510 Screw Driven

Build in 'Cartesian Style CNC' published by msdosfx, Feb 10, 2019.

Workbee 1510 screw driven build by MsDosFX.

-

-

-

- Build Progress:

-

- Build Complete!

Attached Files:

alyssa.ako, CGRTist, wuttisit thungchai and 2 others like this. -

-

Build Author msdosfx, Find all builds by msdosfx

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution - CC BY

Reason for this Build

I built this machine to explore artistic aspects of CNC routing. I wanted to gain a better understanding of creating 3D models, generating tool paths and G-code and the technical aspects of routing and machining. I was also interested in the "open source" and "open hardware" aspects of this CNC and controller. As an artist and art educator, I thought making this machine would provide me with the knowledge to be an asset to Fine Art programs who didn't have a lot of funding but wanted to explore CNC routing in the "open source" realm.