Aluminum OX build with some modifications

Discussion in 'CNC Mills/Routers' started by Dave Zahn, Dec 25, 2014.

Aluminum OX build with some modifications

Discussion in 'CNC Mills/Routers' started by Dave Zahn, Dec 25, 2014.

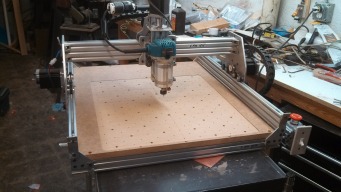

This is my OX CNC router. It has been a labor of love for over a year now! I hope you find it interesting and inspiring! I also hope that it gives some of you more experienced CNC builders a different perspective and some ideas!