Build List

-

Active Filters:

of

Techsoft Roland TS-30 rebuild

Replacing the Electronics and Spindle. Intending to rewire all the buttons and make it into a more modern and easy to use CNC.

Gerber 404 Retrofit

Not sure if the Blackbox X32 is the right option here, just looking for guidance.

Build Author

Joe Young

Views

11732

Build Author

Joe Young

Views

11732

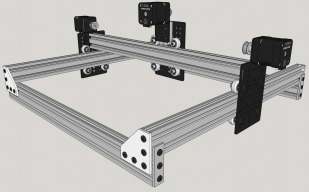

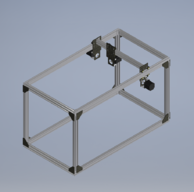

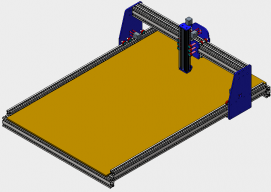

Rack and Pinion (Death to Belts)

Low profile rack and pinion linear actuator design

Build Author

Quentin Karmark

Views

6243

Build Author

Quentin Karmark

Views

6243

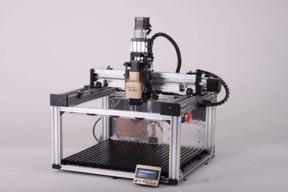

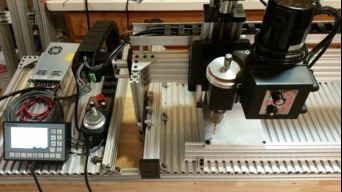

Laguna Swift 4X4 CNC mill retrofitted with OpenBuilds

Used Laguna Swift 4X4 CNC mill with Water-cooled Spindle and RichAuto serial pendant retrofitted with OpenBuilds/Blackbox/Interface

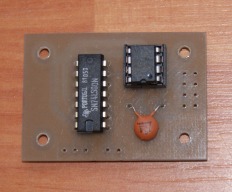

Software speed control of a brushless dc (Bldc) motor from Mach3.

Although this build is typically Mach3 related there is no reason it cannot be adapted for use with any machine control software which provides a PWM spindle control output. As an addition, an option has now been added which will enable the interface to manually control outrunner speed without the need for a PWM signal.

Build Author

Damian V-SLOT Poland

Views

2269

Build Author

Damian V-SLOT Poland

Views

2269

LEGO BOX

Discover our unique DIY project that blends creativity, utility, and sustainability. This guide will take you through the construction of a LEGO display box, ingeniously crafted using offcuts of V-SLOT aluminium profiles and OpenBuilds accessories. Not only is this an eco-friendly approach to reusing surplus materials, but it also results in a stylish, functional display for your prized LEGO models. Whether you're a LEGO enthusiast or have little LEGO fans at home, this innovative project offers

Build Author

Sonny Lowe

Views

5418

Build Author

Sonny Lowe

Views

5418

MakerSL MSL-65 Manual Coffee Grinder Stand

I know this build is a little off category here at OB, but I wanted to share it with the community (as well as other coffee lovers) and show however vast the possibilities are when OB hardware is involved. This is a powered stand intended to operate a manual coffee grinder. It is compact, light, portable and uses simple drive components (B&D Cordless Screwdriver). I will post two version, V-1 (Beginner skill level ) and V-2 (Intermediate skill level). Both accomplish the same results.

Build Author

Jason @ MCC

Views

9675

Build Author

Jason @ MCC

Views

9675

QueenBee Pro CNC Router and Lathe

A 1000x1500mm QueenBee Pro with a 4th Axis Rotary attachment/Lathe Bed.

Build Author

Corey Corbin

Views

5189

Build Author

Corey Corbin

Views

5189

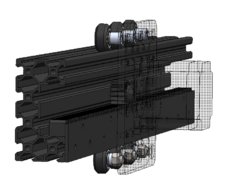

Ball Screw Carrier.

Create a ball screw carrier with out BF BK bearing blocks.

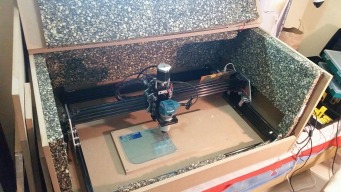

Keeping thing quiet with a custom C Beam XL

A small form factor machine in a soundproof enclosure

Build Author

Yosmany325

Views

1658

Build Author

Yosmany325

Views

1658

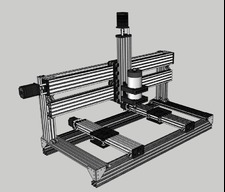

OrionPlus

Cartesian style CNC with a working area of around 360mm x 360mm x 120 mm (X, Y, Z) using Linear rails and ball screws. The linear rails are (Hiwin?) HGR 20mm x 520mm and the ball screws are SFU1204 (12mm lead 4mm) of around +/- 430 mm. The base structure is made from rectangular aluminum profiles of 70mm x 45mm x 3mm (thickness of walls).

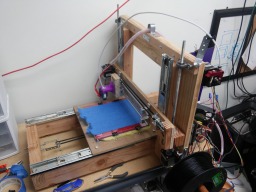

Learning how to build

I made a 5x10 foot cnc out of the parts I bought on this site. It's been upgraded and tinkered with ever since. The end goal is to learn enough to learn to build a large 10x10 foot 3d printer.

Build Author

Braden Masse

Views

2614

Build Author

Braden Masse

Views

2614

Microwave Filter Tuner

The Microwave Filter Tuner (MFT) combined with the University of Regina’s tuning algorithm automatically tunes microwave filters by using a custom CNC machine with a computer vision system for identifying, mapping, and tuning each filter element, providing improved consistency, flexibility, and accuracy compared to traditional methods. The MFT is low cost and is capable of tuning multiple filter configurations with minimal preparation.

Build Author

jeff johnson

Views

4827

Build Author

jeff johnson

Views

4827

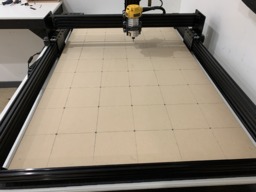

workbee 1510

Getting more height out of the !510

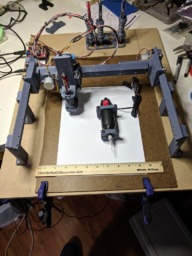

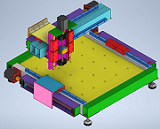

Fully 3D Printed Small CNC Router/Plotter

3D Printed CNC machine. The build is on Thingiverse. https://www.thingiverse.com/thing:3842401 I posted it here to give props to the Openbuilds Control Software!

Build Author

Sir Bagels

Views

2156

Build Author

Sir Bagels

Views

2156

CNC Auto-pipette

Senior Design Project Bennett Robertson, Megan England University of Iowa College of Engineering

Build Author

John J Talavera

Views

17427

Build Author

John J Talavera

Views

17427

CNC FOR EVERYONE!

This build was very complex due to the fact I wanted to create a low cost larger than normal CNC. I did not want a MDF or plastic body. I wanted it to be able to do more than most CNC routers this size on the market.

Build Author

Hidro669

Views

2725

Build Author

Hidro669

Views

2725

My custom world of tanks gaming desk built by Ragged Edge Eaming Solutions

summary huh... If it doesnt fit MAKE IT!

Build Author

Mark Carew

Views

5173

Build Author

Mark Carew

Views

5173

OpenCase Mounting Kit

The OpenCase Mounting Kit makes wire management quick and easy!

Build Author

MrMojoRisin

Views

6494

Build Author

MrMojoRisin

Views

6494

IIOT WiFi Portable CNC Plasma Cutter

IIOT WiFi Plasma CNC.

Build Author

James Evanko

Views

3096

Build Author

James Evanko

Views

3096

Sherline C-Beam with Offline Controller and MPG

This is a C-Beam based router with V-rails used for the bed, a Sherline spindle with Jacobs chuck, closed loop stepper motors on every axis and an offline 4-axis CNC controller. A U-channel was created to guide the drag chain on the X-axis.

Ancient Roland Table top Mill

The parts are now very reasonable.

Soundproof case for Ox

Not much to say... Soundproofing box for noisy works... Build in MDF and 20 mm plexiglas. Very effective!!!

Small Laser Engraver Concept

Low cost Laser Engraver build using all off-the-shelf components.

Roberta Clementine

The Roberta Clementine a proof of concept and progenitor to the series of printers I will be calling the Clementine Sisters. The printer is named after Pittsburgh Pirates baseball player Roberto Clemente. Although it is more accurate to say the printer is named after the school I work for which is named after Clemente the Roberto Clemente Charter School. http://www.myrccs.com Roberta is the first and not really built to last but instead built to test ideas and to produce the parts for successors

Build Author

John J Talavera

Views

7523

Build Author

John J Talavera

Views

7523

CNC FOR EVERYONE, THE DUCK!

www.cncforeveryone.com. the Duck is something that i think would be helpful in my shop since we already do cold casting.

Build Author

Nwrgordon

Views

14601

Build Author

Nwrgordon

Views

14601

RepRap Intro

An easy Epic Win for novice engineers new to the RepRap project www.3distributed.com

Build Author

inhan

Views

5236

Build Author

inhan

Views

5236

openbuilds rovo 1000mmx1000mm(rovo x)(korea)

Open build rovo 1000mm * 1000mm. (Rovo x ver) 20.06.2015 now in progress. rovo kit is the 10th product. 8th rovo 750,9 th rovo1000, 10th rovo x ver progress at the same time. 10th item is an aspect of 1000. It changes the size and z-axis has been up.

Build Author

Mohsen Abbasi

Views

7141

Build Author

Mohsen Abbasi

Views

7141

Portable Foam Cutter

A portable foam cutter to make your forms everyware using a LiPo Battery.

Build Author

Leon Style

Views

4054

Build Author

Leon Style

Views

4054

AluVault MINIMAX

Easy build cnc router with t slot profile and nylon machined part

Build Author

John J Talavera

Views

6852

Build Author

John J Talavera

Views

6852

Rotomolder

A simple low cost rotomolder.