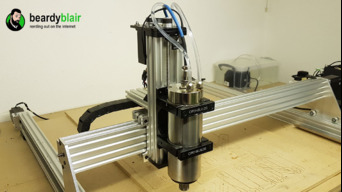

Faced with the choice of buying an off the shelf product that would be a close fit or building something bespoke I trawled the interwebs until I found Openbuilds. I needed something that would cut carbon and alloy parts for rapid internal prototyping of mainly UAV parts. Outsourcing these parts is currently expensive and very slow. We needed to shorten the development phase to gain additional work. The machine needed to be able to work with 800 x 800 mm sheets of carbon and mill to a depth of 50mm for some of our brackets and mounts.

This is my first build using Openbuilds parts so I thought I would go for an easy, well documented and supported project and make the minor additions I needed to make it a near perfect fit. Big shout out to Kyo for help and advice over on his build discussion here.

Going to use this build log to track my build and hopefully get some help along the way, hopefully others will get some use out of it too!

UPDATED to include spindle upgrade info - discussion page 3

Sphinx XL

Build in 'Cartesian Style CNC' published by beardyblair, Oct 7, 2017.

My build log of an adapted Sphinx design with additional height and a larger X and Y axis.

-

-

-

- Build Progress:

-

- Build Complete!

bramuss, hydrotunes, ErichHeubusch and 34 others like this. -

-

Build Author beardyblair, Find all builds by beardyblair

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution Share Alike - CC BY SA

Inspired by

Kyo and his Sphinx CNC