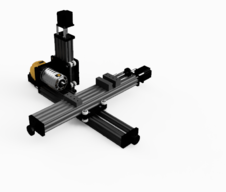

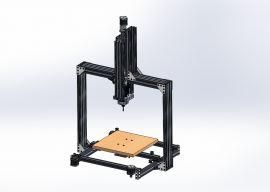

X/Y Table Style CNC Mill

-

X/Y Table Style CNC Mill

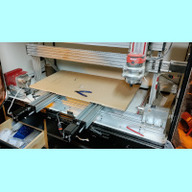

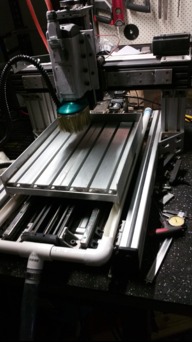

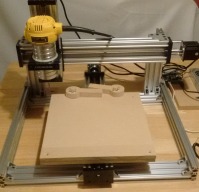

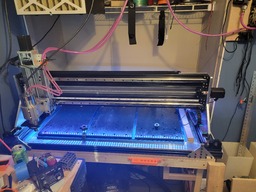

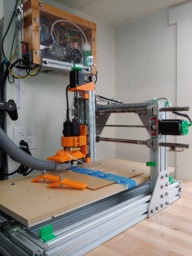

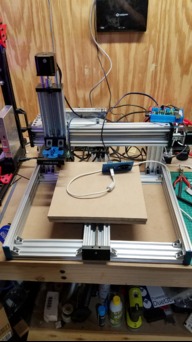

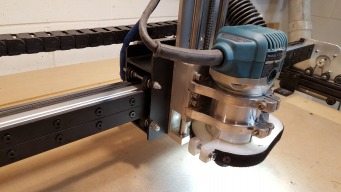

Openbuilds 4x8 cnc

I built this cnc using 2 z axis actuators thinking it would minimize deflection and it seems to be very sturdy. I used 2 1500mm c channels for my x axis, 1 1500mm c channel for my y axis, nema 23 stepper motors, dm556 drivers, 2 24v power supplies, smc5-5-n-n controller, 9mm wide belts, and the Hitachi m12vc router. So far it's working very well with a few hiccups. Programming the controller was a learning experience but I'm very happy with it.

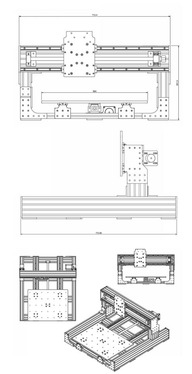

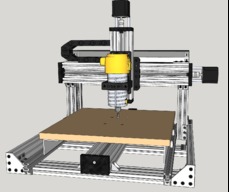

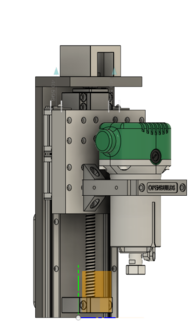

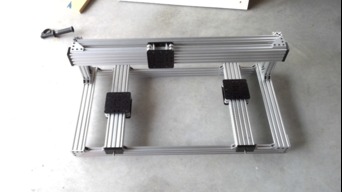

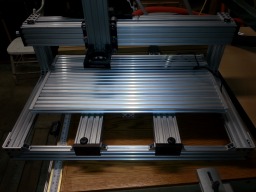

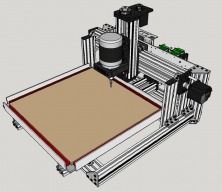

C-beam Machine - Modesty

Modified C-beam Machine. Taller (30 cm) C-beam uprights in gantry, and longer 750 mm frame in Y direction. XL gantry plate on X (and Z?). Y will have additional 700 mm SBR16 rails as extra support and slightly raised bed to fit above stepper motor. Approx. machinable area of 370 x 370 mm.

Build Author

Quentin Karmark

Views

6244

Build Author

Quentin Karmark

Views

6244

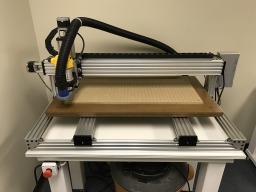

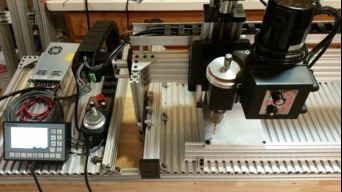

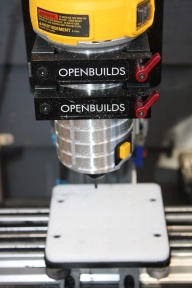

Laguna Swift 4X4 CNC mill retrofitted with OpenBuilds

Used Laguna Swift 4X4 CNC mill with Water-cooled Spindle and RichAuto serial pendant retrofitted with OpenBuilds/Blackbox/Interface

Build Author

Troy Proffitt

Views

24420

Build Author

Troy Proffitt

Views

24420

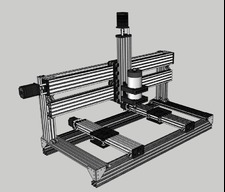

Sphinx Upgraded plates / ballscrews and linear rail

Upgraded Sphinx Cbeam using 3/8 aluminum plates and linear rails / ballscrews

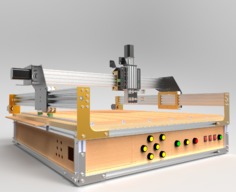

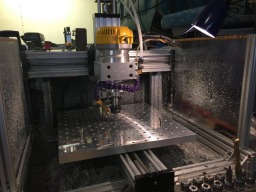

My large machine 48 X 48

This machine is controlled by a Mach3 BOB. I USED Nema 34 stepper motors and a 3kw, water cooled spindle. I’m in the process of adding a vacuum table with 4 zones. I have an X-carve so I use Easel to create G-code for the large machine. I’m currently looking for a way to stabilize the Y-axis. It wiggles a little, so I want to add another linear rail high on both sides.

Reworked Sepcraft 420 CK

Its alive !

Build Author

Yanou Fishel

Views

8824

Build Author

Yanou Fishel

Views

8824

Beefed up Minimill

A beefed up minimill, ready to gnaw on some aluminum! HG15 linear rails, a thick heavy column, bellows and easy fixturing and tramming.

Denford CNC Resurrection

Denford CNC Mill Update

Build Author

alex_b

Views

16776

Build Author

alex_b

Views

16776

TACIT RONIN CNC - Flood Coolant Enabled C-Beam

The TACIT RONIN CNC is a fully enclosed C-Beam platform intended for flood coolant cutting of Carbon Fiber and G10 composites.

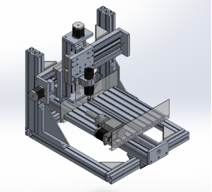

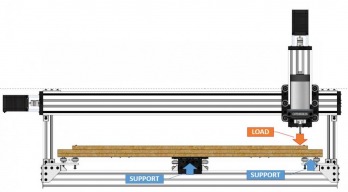

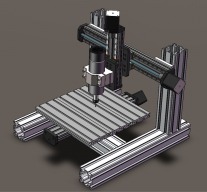

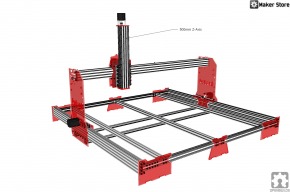

Fixed Gantry CNC Router

A fixed gantry router using OpenBuilds control and electronics.

Fixed Gantry Easy Assembly

Fixed Gantry CNC with good accuracy and rigidity but for a higher price than the usual CNC's on the site.

Y table for LEAD Lathe - essentially a High Z Cbeam XL

I built the lathe as a dedicated rotary axis, but I soon realized I could have a back up CNC for very little expense.

Build Author

Jasont

Views

2722

Build Author

Jasont

Views

2722

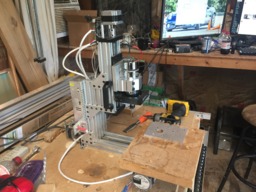

MY first CNC build

my first cnc build using the lead 1010 to build bigger and better!!

Build Author

Rick 2.0

Views

15096

Build Author

Rick 2.0

Views

15096

C-Beam Mini Mite

A small system with a big bite. Design achieves a good balance between machine size vs. build area, rigidity and ease of construction all while keeping build cost as low as possible.

Build Author

Leonard Cross

Views

34185

Build Author

Leonard Cross

Views

34185

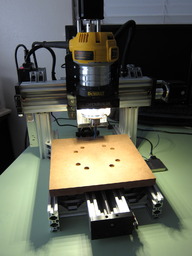

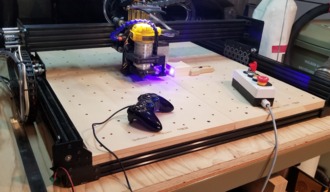

Workbee CNC Router/Laser/Plotter

A CNC machine with an expansive 30x30" work area, supporing a router, laser, simple plotting and work monitoring camera. Control includes a tethered control box, game controller style jog control, and relay controlled AC outlets for all appliances. Accessories include a 3D printed dust shoe, a complete spoilboard and hold down system, an XYZ touch probe and multiple vacuum retention boards to support full profile routing.

My Openbuilds Journey

I've learned a lot from building this machine, and had and will continue to enjoy using it. Let The CHIPS FLY!

MiniMill Z Axis Upgrade with Offset Motor

Upgrade your Minimill with an off-set Z Axis Motor

Build Author

nickchnv

Views

10367

Build Author

nickchnv

Views

10367

Rigid Compact Desktop C-BEAM

This modified C-Beam, is a compact, powerful and affordable desktop CNC.

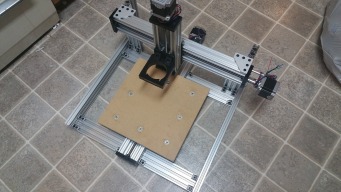

First CNC Router

My very first CNC Router build. It's completely scratch built.

LEAD 710 with High Z mod

Overview of a 700mm x 1000mm machine based on the LEAD design and with the High Z mod from the start. Will have a parts list you can use to build yourself if you like the formfactor

Build Author

Johnny Reich

Views

1139

Build Author

Johnny Reich

Views

1139

ProLight 1000 Mill Retrofit

Update a 20-year old bench top milling machine with OpenBuild Ecosystem electronics.

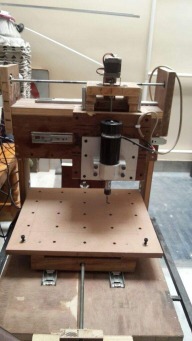

Homemade CNC Router (Under $400)

So Instead of buying a CNC Router which can cost thousands of dollars I ventured on the quest to design and build my own. I have multiple parts to this series. Hopefully all of my information I share helps!

Improved CBM

Yet another build of an improved C-Beam Machine, improving stiffness, size, versatility, and strength without increasing costs much.

Keeping thing quiet with a custom C Beam XL

A small form factor machine in a soundproof enclosure

Build Author

Rob Taylor

Views

9102

Build Author

Rob Taylor

Views

9102

Grizzly G0758 Benchtop Mill Conversion

A proper CNC mill conversion. But quite small, with my trademark idiosyncracies.

C-Beam to C-Beam XL Upgrade

This is my first public build. Please be kind. We upgraded our C-Beam to the C-Cbeam X-Large. I want to give special thanks to Moag and the OpenBuilds team for making this happen.

Build Author

Jose Alezandre

Views

1382

Build Author

Jose Alezandre

Views

1382

Mighty Chihuahua

The idea was to use materials from previuos failed projects into a succesful one. I have build this tiny but powerfull CNC machine mainly using the universal gantry plates for the X and Y axis. Also another innovative part is the fact that I assembled the Z gantry with 2 aluminum sections of 20X40 and one aluminum seccion of the 20X20. I used NEMA 17 stepper motors with GT2 pulleys. This was designed on Fusion360

Horizontal CNC V-Beem v1

V-Beem horizontal milling machine built on OpenBuilds components. Simple structure, great expansion possibilities, high stiffness.

Build Author

dreys

Views

10309

Build Author

dreys

Views

10309

Was once a mini mill

Working progress.

My Ooznest Workbee V2.0 build

I'm new to this whole process, so this is a build by a newbie for newbies.

Workbee Z-axis Upgrade

Z-Axis upgrade with linear rails, SFU1204 Ball Screw and full aluminium construction.

ApiNui - CNC Router ( an oversized workbee )

Based on the WorkBee CNC, this is an oversized router built with a specific use-case in mind, for manufacutring beehives, and beehive components

1000 x 1000 Workbee powered by X controller

A standard 1000x1000 Workbee powered by an X-controller using a Hitachi router

Joe's Minimill Build

I put this together to cut aluminum. Chips get everywhere! Cover your lead screws. Put the mill inside an enclosure. DON'T mount electronics (especially the power supply) inside the enclosure, chips will get into it and short it out. Remove the manual jog wheels, they contribute to chatter (something about having a mass on the end of the lead screw causes vibration). I cut at 14000 RPM, 0.05 inch width of cut, 0.05 inch depth of cut, 30 inches per minute and just barely avoid chatter.

Behemoth cnc router with linear rails

Behemoth cnc router build in progress using hiwil rails and closedloop servos.

Build Author

Andrew Helsel

Views

11130

Build Author

Andrew Helsel

Views

11130

MiniMill Smoothie

MiniMill with DW611 and SmoothieBoard 4x v1.1

Build Author

MattR

Views

15121

Build Author

MattR

Views

15121

Fixed Gantry CNC Router with Old Industrial Supplies

I got lucky enough to purchase aluminum extrusions and linear motion components (and nuts/bolts/etc) at scrap metal prices when a bunch of industrial automation equipment was decommissioned. The only problem is that the aluminum extrusions are not metric sizes... they are the 1.5"x3" 80/20 series. It has presented a few challenges but nothing too bad.

Cnc Mill using standard and 3d printed cimponents

I used the cad designs for the c beam to find a solution to my initial sourcing problem. I figured that I could use 2x 20x20 and 1x 20x80 Profil to create a c beam actuator. I sourced all of the profiles from a local machin builder and t-nuts and screws in my local hardware store. Some parts are currently in 3d printed pla for testing reasons.

OX (Large) CNC

Building a Large OX CNC Open Build on a fold down table.

Build Author

Metalguru

Views

13052

Build Author

Metalguru

Views

13052

C-Beam Machine Too

C-Beam Machine upgrade using linear rails to increase machining size by 2.5 times and increase rigidity

OoozNest WorkBee

A Journey on the WorkBee Build...

Build Author

Rob Mahan

Views

11742

Build Author

Rob Mahan

Views

11742

Rob's C-Beam Machine XLarge

This is my first CNC router build, so I started with the OpenBuilds C-Beam Machine XLarge mechanical bundle, including four high torque stepper motors. I took my time with the mechanical build, sought and found some great help for my control system, and designed and built a custom cabinet to house everything.

CNC by MagicMarcus

CNC variation about Sphinx.

OXmill

Small Mill type CNC machine, using C-Beams and V-Slot rail, bundle packs as a starter point. I needed a smallish desktop machine to fit a pretty narrow use case for my business, but the machine itself has larger applications to the OB community. Currently I will run the Dewalt 611 router on the Z axis, but have plans to add in a brushless RC style motor. So this design does have room to go either way easily.

Build Author

Lindsey Lewis

Views

6642

Build Author

Lindsey Lewis

Views

6642

CNC Mini Mill Build

CNC Mini Mill build with some mods after following standard build on Youtube video.

Build Author

ChrisViral

Views

5893

Build Author

ChrisViral

Views

5893

OP C-Beam Machine XL by ChrisViral

Video diary C-Beam XL build with massive steppers and a 1.5kW Chinese spindle.

Build Author

James Evanko

Views

3097

Build Author

James Evanko

Views

3097

Sherline C-Beam with Offline Controller and MPG

This is a C-Beam based router with V-rails used for the bed, a Sherline spindle with Jacobs chuck, closed loop stepper motors on every axis and an offline 4-axis CNC controller. A U-channel was created to guide the drag chain on the X-axis.

Phil's Workbee

Wanted a nice project to work and learn on... now have a big CNC to play with A 1500x1000mm Workbee

Phil's MiniMill

A quick little mini mill build

Yamm (Yet another MiniMill)

First time CNC user having a good time with a MiniMill

Big-X Minimill

Minimill bundle, but with an extended X Axis

Minimill with slight modifications and v-slot table

This is a slightly-modified OpenBuilds minimill with some more Y travel and a v-slot table.

Horizontal MiniMill (x5)

The search for an affordable hobby 5 axis machine.

Build Author

Janis93

Views

13825

Build Author

Janis93

Views

13825

1000x1000 Two version of router Belt and Screw

Cheap sheet metal gantry solutions, for diy belt driven cnc and screw driven cnc.

C-Beam Machine - MyFirstCNC

This is my first foray into CNC machines, after much review I decided on the C-Beam machine as it seemed easy to work with and will enabled me to build more and larger machines as I gain knowledge. I am planning on building the machine largely unmodified from the reference design. I will be building the machine an axis at a time as I need to spread out costs over time.

Build Author

obmilllivebuild

Views

4765

Build Author

obmilllivebuild

Views

4765

Live C-Beam Build @ MRRF2018

Contained within are links to our OpenBuilds sponsored C-beam Machine live build taking place at MRRF 2018 (Midwest Reprap Festival) on March 24 and 25, 2018. There will also be some build images and a few 3D printed STL items that were added.

Noob 1000Sphinx

A complete noob stumbling thru his first cnc build in winter.. and trying to find the time with 2 toddlers..

Build Author

ymilord

Views

21499

Build Author

ymilord

Views

21499

C-Beam Rigid - 'The Hog'

C-Beam Machine baseline build. DW618 Spindle. SuperPID. Gcode Controlled Mist Coolant. Rigid Work Surface. NEMA 23 (425oz-in) Leadshine 4 Axis Stepper Driver. LinuxCNC (MachineKit) Tool Touch Off Probe.

Build Author

JAC_101

Views

4970

Build Author

JAC_101

Views

4970

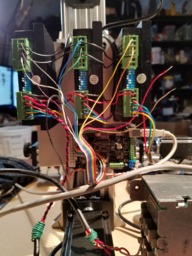

Small PCB, Engraving and Delrin CNC Mill

This is my first attempt at building a spindle based CNC machine. The intention is to mill PCB boards and mill delrin blocks. The device was built with an Emergency Stop that actually cuts power to the spindle and motors. This is a post build write-up and consists of finished photo compilation and CAD renderings.

Beefed-up and customized OX build

My Machine is based on the OX CNC designed by Mark Carew as well as the ooznest kit, and it incorporates a bunch of my own details and revisions to increase performance and robustness. It has become way more beastly than I originally planned!

Bedroom Builds (BrB) DIY CNC

So I am employed in the automotive industry and I walk by thousands of dollars of CNC products daily that are no use to me due to being a Technologist and not a machinist. So therefore with some research I found openbuilds and their great selection of products to build my own CNC. This CNC will consist of 4 axis one removable 360 degree axis for turning alongside a x axis table Y axis stationary gantry and a Z axis attracted to the Y axis linear actuator.

Build Author

Rob Withoff

Views

3881

Build Author

Rob Withoff

Views

3881

Mini-Mill Enhanced

Some enhancements of the basic mini-mill

Build Author

bpatterson42

Views

2483

Build Author

bpatterson42

Views

2483

Inverted Y C-Beam Machine

Similar to C-Beam Machine build, but with inverted Y-axis assembly to shield drive screw. Integrated XZ gantry can be fixed to any solid surface. Build dimensions are 36" x 36" x 6".

Dogmeat's Custom C-Beam XL

I love the C-Beam XL concept, this build is my custom version with the goal of increasing rigidity for metal milling.

Build Author

Carl van Heezik

Views

7260

Build Author

Carl van Heezik

Views

7260

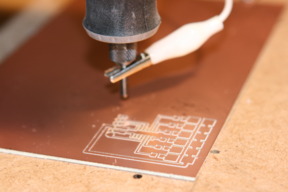

C-Beam™ Machine for PCB milling

C-Beam Machine for PCB milling

Build Author

Teflon4

Views

15026

Build Author

Teflon4

Views

15026

TZ C-Beam Machine Plate Maker

A Modified and augmented Ooznest C-Beam Machine Plate Maker.

RSW's C-Beam Build

I built a CNC Router using 3/4 MDF, 1/8 aluminum angle for bearing races and various other odds and ends. I learned a lot about how not to build a CNC router. I found Openbuilds.com and decided to build a C-Beam for my first build. The long term idea is to use this machine to build custom plates for and OX type machine and a 3d printer.

Build Author

ShockingTops

Views

3604

Build Author

ShockingTops

Views

3604

Opening into doors

Construction of a CNC table for a specific project that could cut an area larger than a door (>8'x4'). Much thought went into how to avoid the weight of the gantry bending the (long) Y axis, whilst still keeping down the complexity and cost.

Desktop PCB Maker

With the focus always on larger builds I wanted to focus on a desktop PCB milling machine that fulfills the average users desktop needs at an entry level cost. Design considerations will allow expandable capabilities to include 3D printing and any other functions a small form Cartesian robot can perform. The current iteration has a desktop footprint of approximately 15.5" X 14.5".

C-Beam Elexa

This build will be based on the C-Beam Plate Maker, with additional changes based on other builds and ideas.

Build Author

JWhitten

Views

12985

Build Author

JWhitten

Views

12985

Build #2 - Bigger & Stronger

Large format CNC router with a 1500mm x 3000mm cutting envelope (5 x 10 ft) strong enough to cut wood and aluminum constructed from 20-series and 40-series aluminum extrusions. Complete Project Log w/ Pictures: https://goo.gl/photos/Co81AvGwVijE2zow9

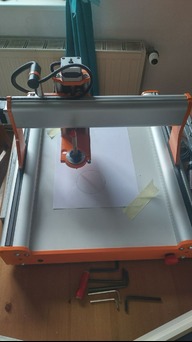

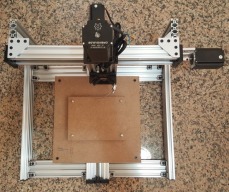

First build - small scale

Using basic standard components, beams, motors, belt drive on x and y, z is a screw. Using Grbl Panel on Windows 10. Really basic router, had trouble getting the controller to turn on the router and set speeds so it is currently wired to a power bar switch so it runs full speed and I just use the switch to turn it on and off. Just getting x, y and z control working properly for now and likely going to switch the router to my dremel 4000 using a 3d printed mounting bracket I got from thingiverse

Build Author

ZacharyB

Views

4618

Build Author

ZacharyB

Views

4618

Arizona OpenBuilds MiniMill CNC

I ordered the OpenBuilds MiniMill from the OpenBuilds Parts Store http://openbuildspartstore.com/ They were out of Motors and Electronics when I ordered so I had to source these items elsewhere. But it turned out well doing it this way.

Build Author

jamesdjadams

Views

11255

Build Author

jamesdjadams

Views

11255

C-Beam XL - TinyG - Aluminium Plate - Dewalt 611

C-Beam XL build using TinyG V8.

Ancient Roland Table top Mill

The parts are now very reasonable.

Build Author

DaveStewart

Views

5192

Build Author

DaveStewart

Views

5192

Small C-Beam Plate Maker With Remote Login & Operation

C-Beam Plate cutter with Raspberry Pi V3, Arduino Mega2560 and Camera. Remote login & operation via SSH with cnc.js server, mjpg server on the Pi.

Build Author

Kyo

Views

8604

Build Author

Kyo

Views

8604

Plate Maker V-slot Table

C-beam Plate Maker V-slot Table System to aid in clamping and setup of jobs.

Vertical Mill

This will be a CNC milling machine. My goal is to make this mill for the minimum cost I can while not sacrificing quality. In hope of staring an educational YouTube channel on CNC milling and 3D Printing. Along with when to use both.

my version of xl

A table top version of the open build xl router kit set build. This use of c - beam and xl kit set was coupled with Mach 3 controller running on Dell opti -plex 755 and win 7 pro licence. A Dell opti-plex 755 empty case was used to house the controls and wiring , including the limit switch and emergency stop safety circuits

C-Beam XL ( 1 meter²)

A modified C-Beam Build with a few Addons

Desktop CNC machine

Stable solid, hope can cooperate with coolant in the future.

My MiniMill is just the start

This is my first build and I've been waiting to do this for a very long time.

C-Beam "2" XLarge CNC Router

C-Beam 2XL CNC Router

Build Author

Jason Harding

Views

3211

Build Author

Jason Harding

Views

3211

Mobile bed cnc machine, first build

Currently i am reworking the frame still with current available parts just going to buy material to make the y and the z axis from openbuilds. The x axis is now going to be mobile similar to a 3d printer style.

PCBman CNC

This is a design for a desktop CNC machine. It may be a router or laser. I am undecided as to the final design.

Build Author

Greg Lampman

Views

8212

Build Author

Greg Lampman

Views

8212

C-Beam Intro to CNC

Build log for my first CNC machine, a C-Beam Plate Maker

Build Author

M^3

Views

20621

Build Author

M^3

Views

20621

M Cubed CNC Mill

A no-nonsense CNC mini mill to get the job done.

Build Author

Karan Singh Sisodia

Views

5345

Build Author

Karan Singh Sisodia

Views

5345

My Home made CNC

Home Made CNC Router from Scrape

Build Author

Sonny Lowe

Views

6058

Build Author

Sonny Lowe

Views

6058

The MakerSL Customized OB Minimill

This is my interpretation of the OB Minimill, what I've changed so far, and what may continue to change as my requirements change.

CNC Planning

Reusing parts to build a CNC - planning stage

First CNC Build

Building my First CNC for PCB milling. Some modification done to the original build from OpenBuild Bundle.

MiniMill - A must have machine :)

The new MiniMill from Mark and Sonny is a great little machine.

C-Beam XL build

So for a summary its a great kit that was easy to build, could not be more happy.

CoreXY Tower

CoreXY Table with Symmetric Lead Screw Z axis, Build volume: 293mm x 290.75mm x 223.83mm

c-beam hello world

My first ever build. Straight C-beam with tinyg controller a few do-dads and some make do choices. Non-metric length lead screws to save long lead time. Jog knobs to cover the extra length and also practical. My old Bosch Colt never had it so good. Build out work remains, wire dressing, drag chain, vacuum, permanent base, etc.

Jim's C-Beam Machine Build

This machine is fantastic. Teamed up with Fusion 360, Inkscape, and GrblPanel, I'm well on my way towards making at least one Christmas gift this year. I had some frustrating times during the build, mainly with getting everything to go together square, but overall it was fun. I can see that I'm going to need to be a bit creative in order to max out the work area for this machine so that I can produce the product I bought it for, but it will be able to do so much more for me as well.

C-Beam XL with Aluminum Bed

C-Beam XL with v-slot aluminum bed for fixturing.

Build Author

Joe Garritano

Views

9894

Build Author

Joe Garritano

Views

9894

X-carve upgrade

Using criticall OpenBuilds components to upgrade the rigidity and reliability of an X-Carve 1000mm build.

My first CNC - The C-Beam Basic

I am a newbie and this is my first build. After hours and hours of research I decided on the C-Beam. I will be changing one or two things but I will basically be building this as per Mark's video.

New Custom CNC with C-Beam Rails

Hello all, wanted to share my custom build that I planed to do. My idea was to drill foam blocks to make molds for my projects. The CNC will be 1500-1500mm with a higher Z-Axis. So I redesigned the Gantry Plates that will be cut out at some other place. I hope you can share your opinion on my project.