X-carve upgrade

Discussion in 'CNC Mills/Routers' started by Joe Garritano, Aug 23, 2016.

X-carve upgrade

Discussion in 'CNC Mills/Routers' started by Joe Garritano, Aug 23, 2016.

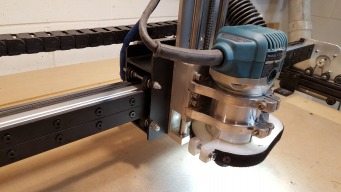

Using criticall OpenBuilds components to upgrade the rigidity and reliability of an X-Carve 1000mm build.