Other Style CNC Mills

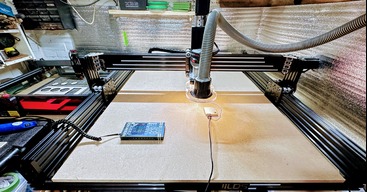

My Lead 1010

This is a fully loaded Lead 1010 and located in a shed measuring 3 by 2.50 meters. Here i build my guiyats by hand and the help of my Openbuilds friend! Pure for hobby.

Build Author

EvanH

Views

1600

Build Author

EvanH

Views

1600

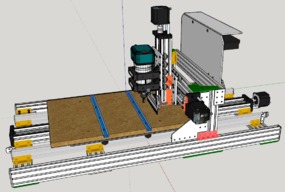

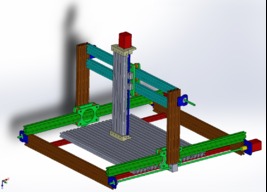

"Hawk" Heavy-duty dual-Z pseudo C-Beam

A compact, strong machine with very high Z clearance, yet can still mill aluminium easily.

CNC built, work in progress, fail

2x4 cutting area, enclosed with dust collection mainly built out of wood.

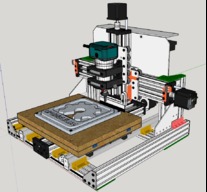

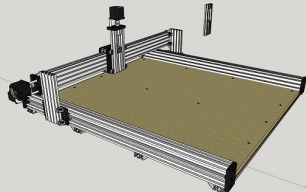

C-beam charmer

Double C-beam Y axis 500mm., Double 2080 X axis 600mm. , C-beam Z axis 250mm, TB-6600 drivers, MKS-DLC32v2 GRBL w/wi-fi and blue tooth

Robo Morten

A horizontal-router CNC using openbuilds parts geared toward routing out mortise and tenon joinery; or any other end grain work on wood.

Gauss Probe Machine

Standard build with high Z using a Gauss probe instead of a router.

Build Author

theracermark

Views

3026

Build Author

theracermark

Views

3026

Reviving the Origonal PhlatPrinter with BlackBox

Reworked PhlatPrinter Gen1 Adding dual nema 17s to all 3 axis Supprot for carriage to insure even dept cuts Lighting for view of cutting area

Pro Light 1000 CNC Machining Center Rebuild

Replacing the Pro Light control box with a Open Builds BlackBox.

The dwarf

This is a build for those of us that want to work fairly large but are in a tight space and budget

CNC China Router Conversion to Open Builds System

China Router frame with linear bolts, Nema23 and the icing on the cake “open build parts“

My C-Beam machine...from 500 to 1000mm base

C-Beam machine - 1000mm base.

My C-Beam machine...

A C-Beam machine design, strengthened with extra brackets and plates. GRBL controlled, opto-isolated inputs, jogging box.

PhlatMDF48

Building a Phlat based CNC for MDF processing. Capacity of 48" x unlimited length.

My Workbee build

Workbee, 1000mmX750mm , from China

Build Author

Vunnie

Views

5874

Build Author

Vunnie

Views

5874

Workbee CNC on steroids

My First major improvement was changing the controller to a Acorn board. I loved the way a dedicated userinterface was speeding up my workflow. Next project my Y Axis. On Aliexpress I ordered a couple of 16mm ballscrews and some lineair rail. Before I took my gantry off I quickly made some aluminium profiles to fit my carriages. Withouth any doubt these improvements where worth it

cnc vreesbank 2500x30000

This cnc milling machine is 3 meters by 30 meters,

CNC 1000x1000mm C-beam

inspired by http://openbuilds.org/builds/c-beam-sphinx.3605/

Reworked Routkit SD

I could not "tram" the spindle to the table. I found that the V Rails could not accurately be adjusted so the Gantry was equal distance from the spoilboard in multiple places.

CNC Router Machine

CNC Router with working area 550*550*200

Build Author

John J Talavera

Views

17427

Build Author

John J Talavera

Views

17427

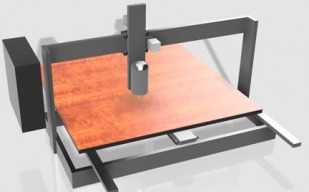

CNC FOR EVERYONE!

This build was very complex due to the fact I wanted to create a low cost larger than normal CNC. I did not want a MDF or plastic body. I wanted it to be able to do more than most CNC routers this size on the market.

Build Author

Mark Carew

Views

32772

Build Author

Mark Carew

Views

32772

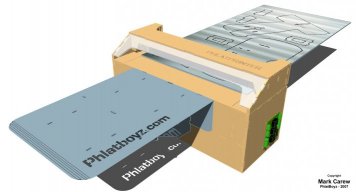

PhlatPrinter MK 3

The Phlatprinter 3 was designed to be used in a small shop with the ability to cut large sheets of foam for RC airplane projects. The idea was that you could save all of your aircraft as models and tweak to perfection after every flight.

Build Author

Mark Carew

Views

71460

Build Author

Mark Carew

Views

71460

Original PhlatPrinter

Phlatprinter foam cutting CNC machines are awesome space saving mills that use a rotary axis as a sheet feed.

Solid basics CNC router

This build focuses on the basics to provide a good foundation to further enhance the ability to achieve tight tolerances

C_Beam Hammerhead 5x

setup for learning 5x

Build Author

Gooshpoo

Views

8066

Build Author

Gooshpoo

Views

8066

Gooshpoo's H style cnc machine

A cool project about my cnc machines unique style.

Generic 6 Axis Controller

Generic 6 Axis (Stepper) Controller

Build Author

Rakmup

Views

39697

Build Author

Rakmup

Views

39697

CNC Router Lathe

Steel square tube frame with dual feed gantry and indexing lathe section. Will have 36" x 30" x 6" travel. Has a Harmonic Drive on the 4th Axis.

Build Author

Ronald van Arkel

Views

15397

Build Author

Ronald van Arkel

Views

15397

Upgrading the C-Beam machine

So we have new plates, stronger motors, belt drive reduction, but what should we do with them? In this article you might find the answer you were looking for as we took an “old” C-Beam machine and started to upgrade the X/Z body and added more torque and precision to the Z-axis.

The Budget Build

An affordable large CNC machine, that so far has been easy to assemble

Triangular CNC Milling Machine

A wonky build to eliminate slop on a long Z axis

SUPER OX NEMA 34 1600 OZ Motors!!!

CNC OX 1500X3000

CNC Rotary Table Rotational Axis, A Axis B Axis 4th 5th Axis CNC Dividing Head

This is my first major project.

eeYZee Router

The first criteria was portability, the second was cutting out a sheet of ply, the third was the ability to shape a foam surfboard blank, but the main criteria was a small budget.

My First CNC Machine

This will be a step by step record charting my successes and failures in my voyage of discovery while building a CNC router. Please excuse my English-English which may lose something in translation to American-English. I would be grateful for any advice during the build

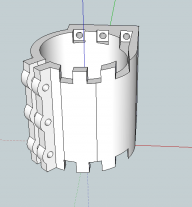

20x60 to Dewalt 611 Mount (a.k.a the Rook)

Dewalt 611 Router mount for mounting onto 20x60 v-slot

Build Author

CubeSpawn

Views

14856

Build Author

CubeSpawn

Views

14856

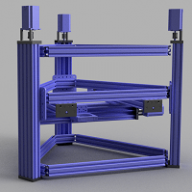

CubeSpawn 3 Axis Mill Module

Small Form factor based 3 axis Gantry style mill, Removeable mechanical module. Removable Electronics. with a removable machine pallet, for automation.

Build Author

Mark Carew

Views

13775

Build Author

Mark Carew

Views

13775

Phlatprinter MKII

Phlatprinter MKII Foam Cutting Machine

Meister-CNC

This is a cnc router with 3 axis and a kress 1050 motor. Its 140x120cm and a homebuild with your help!

Build Author

Richard Bugland

Views

7997

Build Author

Richard Bugland

Views

7997

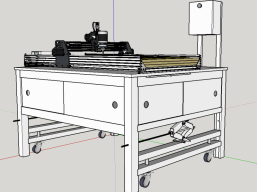

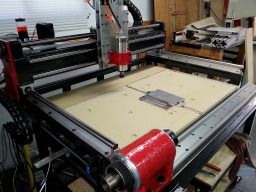

Heavy Inexpensive CNC

Acquiring a CNC has been on my list for some time now. This concept is a bare bones, upgradeable machine that will not require a complete rebuild when new parts become available. With a cutting surface over 36" square, this beast should be capable of creating its own parts. Lowering the price to make upgrading and making this contraption beefier, faster, and more precise.

Build Author

John J Talavera

Views

10993

Build Author

John J Talavera

Views

10993

CNC FOR EVERYONE TITAN CNC ROUTER

www.cncforeveryone.com TITAN CNC ROUTER is the perfect PCB milling machine or for smaller projects. Don't be fooled by its small size it is capable of routing with the big boys...!