Build List

-

Active Filters:

y

Dedicated Compact Rotary Axis Laser Engraver

Compact Dedicated Rotary Axis Laser Engraver

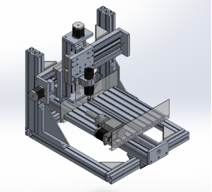

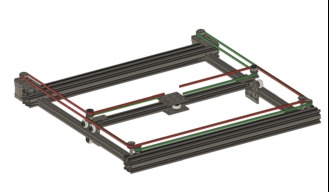

Rotary Axis OX Derivitive

A Rotary Axis CNC router based on the OX CNC Router

Build Author

Neil Rosenberg

Views

35011

Build Author

Neil Rosenberg

Views

35011

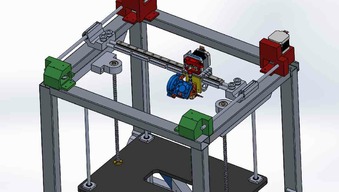

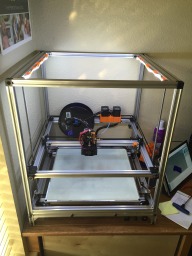

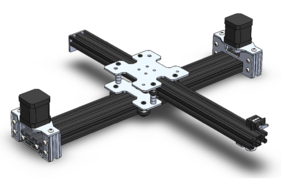

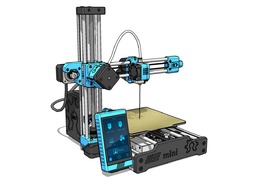

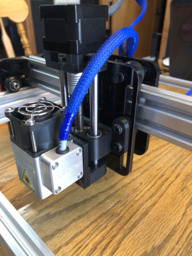

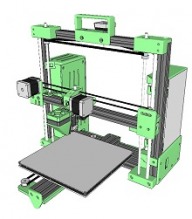

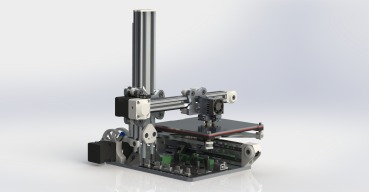

Dash-X 3D Printer: Innovative design

Cross-beam Cartesian 3d printer with dual master/slave lightweight fiberglass drive shafts, BMG style extruder with Bowden (Capricorn) tubing. Hot end is Creality Ender 3 style with two fans and BLTouch for autoleveling. Filament runout sensor is also included.

Build Author

Michael.M

Views

35353

Build Author

Michael.M

Views

35353

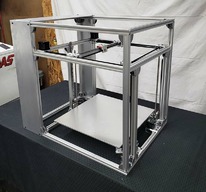

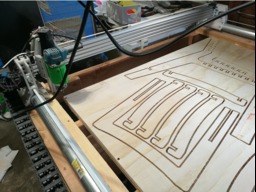

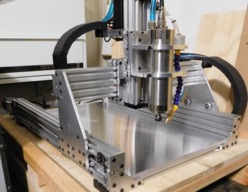

7050 Sphinx

This is a Kyo Sphinx CNC Router build. Working Area: 350mm X 500mm Link to original design: https://openbuilds.com/builds/c-beam-sphinx.3605/

Build Author

Mark Carew

Views

18637

Build Author

Mark Carew

Views

18637

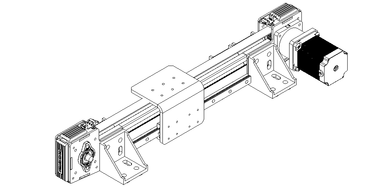

V-Slot™ Nema 23 Linear Actuator (Belt Driven)

This example build shows how easy it is to make a linear actuator using a few OpenBuilds Parts.

Build Author

OpenBuilds

Views

22295

Build Author

OpenBuilds

Views

22295

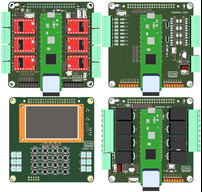

INTERFACE CNC Touch Control System

Super cool standalone Human-Machine Interface for controlling your CNC machines!

Build Author

EvanH

Views

827

Build Author

EvanH

Views

827

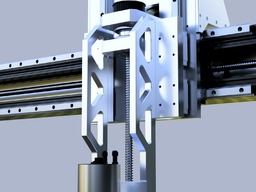

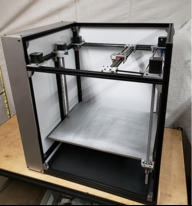

"Hawk" Heavy-duty dual-Z pseudo C-Beam

A compact, strong machine with very high Z clearance, yet can still mill aluminium easily.

Build Author

Keith Davis

Views

19519

Build Author

Keith Davis

Views

19519

Vulcan MAX

While mimicing the frame platform of the popular Crealiy CR-10 and Ender series, the Vulcan MAX overcomes design weaknesses in both printers. Chief improvements are a more stable, rigid mounting of the Z frame and Z gantry.

Build Author

Mark Carew

Views

73275

Build Author

Mark Carew

Views

73275

BlackBox Motion Control System

The Openbuilds BlackBox is a new system evolved around a set of subsystems that cover more than just control and also more than just CNC type applications! With a plug-and-play easy connection system this controller can be used with ease, without sacrificing power.

Build Author

cdsmith12

Views

24207

Build Author

cdsmith12

Views

24207

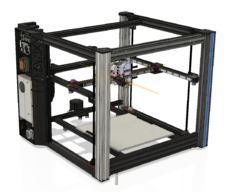

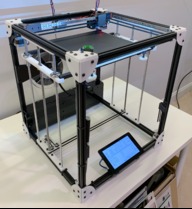

The Plastic Beast CoreXY Printer

In my opinion, this is the easiest and most complete tutorial to walk you through building a large platform 3D printer and the Sketchup File is included for you to make any changes needed.. The Plastic Beast is a CoreXY Printer with a build platform of 440mm square. You can print 600mm or about 23 inches diagonal. Any level of user from novice to expert should gain something from my tutorial.

Build Author

openhardwarecoza

Views

71109

Build Author

openhardwarecoza

Views

71109

openBuilds FreeBURN-1 V-slot CO2 Laser (60-100w)

DIY Lasercutter: Budget orientated, medium sized (60-100w), safety first, based on Lasersaur software toolchain

Hydraulic lifting table

I started this project without drawing. in itself this went fine with some minor adjustments. My profession is machine builder that might make it a little easier. I still enjoy it every day.

Build Author

sausagePaws

Views

72391

Build Author

sausagePaws

Views

72391

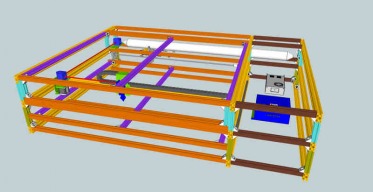

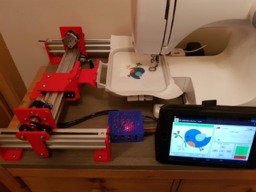

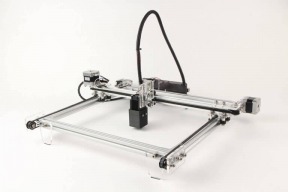

Embroidery machine with XY belt and pinion drive.

A simple Embroidery machine using an XY belt and pinion drive to drive a hoop under a standard sewing machine. Needle timing, machine power and stepper control are all provided by a PIC processor. A tablet provides the higher level formatting required for communicating with the PIC chip.

Build Author

Mac6986

Views

14987

Build Author

Mac6986

Views

14987

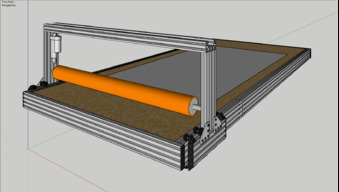

Vinyl Application Roller table

Build progress of custom roller table for applying graphics

Build Author

Gerald Klein

Views

13180

Build Author

Gerald Klein

Views

13180

300mm Diameter, 1 Meter tall, Delta 3d Printer

I built a custom delta using 3, 1000 mm long C-Beam® Linear Rails and 3 C-Beam Gantry Sets. I had the bottom and top plates water jetted ( for accuracy ) out of 1/2 inch aluminum, from a design that I did in Fusion 360.

Build Author

Kyo

Views

29952

Build Author

Kyo

Views

29952

Sphinx 1050

This is going to be a Sphinx 1050 build. Starting off as a stock kit build using industrial electronics and opensource control software. Mods and upgrades to follow.

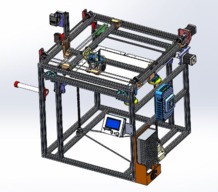

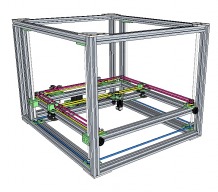

Gauthali V2.0 DIY 3D printer

This is based on core XY kinematics. First of all, we designed a CAD model. Most of the required parts are designed by us in solidworks software, and some parts are downloaded from a web platform ‘grabcad’. After that we assembled those parts and inspected them in solidworks. The designed CAD models are frame of 470mmX392mmX545mm SBR linear guide rod, linear guide holder, lead screw, motor mounts, pulley, bed mount, idler block, timing belt clamper.

Build Author

alan richard

Views

45136

Build Author

alan richard

Views

45136

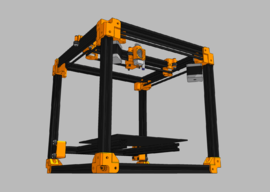

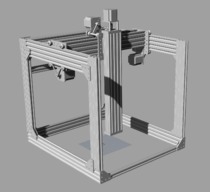

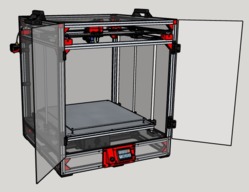

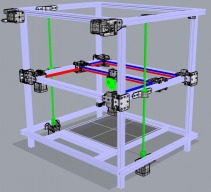

Core-XY Cube

An enclosed cube shaped 3D printer using CoreXY motion. Fabricated from V slot extrusion, standard extrusion, aluminium plate and acrylic sheet using basic workshop tools. Using standard RAMPS/ Reprap electronics. Technically a 'Repstrap' currently used to build a true 'Reprap'

Build Author

Rob Taylor

Views

15517

Build Author

Rob Taylor

Views

15517

M4: 1510SS Heavy Mk.I

A 1500x1200mm, 20mm rail and 1610 ballscrew, heavy-duty, four-axis gantry machine. As high speed as spindle power MRR will allow for. Approx 4 x 3 x 1ft travels, intermediate size between benchtop and floor-scale units. Aiming at $10-15k machine in the $3k region.

Build Author

Keith Davis

Views

32222

Build Author

Keith Davis

Views

32222

OneZ i3

A quiet, 8inx8in build area, Cartesian printer with permanently level bed. This is a compact, solid, inexpensive printer that will reliably print any type filament for thousands of hours while you sleep, fish, or play ball in the park.

CNC Linear Slide for DIY project

Low cost cnc linear drive for making any xyz cnc structure

Build Author

Mark Carew

Views

13199

Build Author

Mark Carew

Views

13199

C-Beam XLarge X/Y Table

This OpenBuilds C-Beam XLarge X/Y Table is a great display of how easy it is to modify and create awesome configurations with the OpenBuilds system!

Build Author

OpenBuilds

Views

12219

Build Author

OpenBuilds

Views

12219

C-Beam® Tension XL Linear Actuator

Bringing your lead screw precision and accuracy to new lengths using a simplistic tension system!

Build Author

MattR

Views

16521

Build Author

MattR

Views

16521

Cricut Expressions 2 to ESP32 GRBL Control

A log of my "brain surgery" on a Cricut Expressions 2 to change the control board to something open so that I could cut what I wanted. The ESP32 GRBL board I used has bluetooth and WIFI built-in and was very easy to get working just the way I wanted.

Build Author

Damian V-SLOT Poland

Views

1771

Build Author

Damian V-SLOT Poland

Views

1771

LEGO BOX

Discover our unique DIY project that blends creativity, utility, and sustainability. This guide will take you through the construction of a LEGO display box, ingeniously crafted using offcuts of V-SLOT aluminium profiles and OpenBuilds accessories. Not only is this an eco-friendly approach to reusing surplus materials, but it also results in a stylish, functional display for your prized LEGO models. Whether you're a LEGO enthusiast or have little LEGO fans at home, this innovative project offers

Magnetic CNC Dust Shoe with LED lights and Camera*

Making my own magnetic dust shoe with led lights and a camera. Showing my progress from beginning to now.

Build Author

UltiBots

Views

34133

Build Author

UltiBots

Views

34133

UltiBots CB3030 CNC Router

The UltiBots CB3030 CNC uses C-Beam, V-Slot and an extruded aluminum T-Slot work table. This allows 6mm T-Nuts, step clamps and blocks to secure materials to the work surface. The all metal design makes the use of a mister possible.

Build Author

2SIsurf

Views

4235

Build Author

2SIsurf

Views

4235

Hotwire cnc Surfboards

Xl 2 axis foam cutter Eps Surfboard blanks Simple open concept but high production machine. Shape 3d case with open builds controller

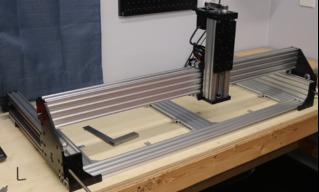

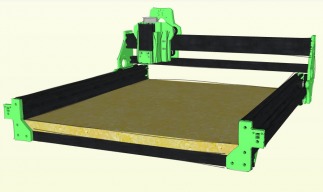

Custom 4x4 CNC

I started designing and ordering parts for this build back in Oct 2021. Unfortunately life got in the way and I had to sideline the project to deal with more important projects. I am now back working on this project full time. I originally was building a MPCNC on this torsion box platform I built but quickly realized how difficult it would be to produce anything with good accuracy. So I decided to design my own CNC that would be more robust and accurate.

Build Author

alex_b

Views

16416

Build Author

alex_b

Views

16416

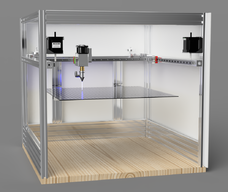

TACIT RONIN CNC - Flood Coolant Enabled C-Beam

The TACIT RONIN CNC is a fully enclosed C-Beam platform intended for flood coolant cutting of Carbon Fiber and G10 composites.

Laser Rotary Tool / Attachment

Rotary attachment to engrave cylindrical objects on laser machines

Budget friendly starter build

DIY CO2 laser build. Budget friendly, 2020 T/V-slot profiles and scalability.

Build Author

Ted Moyer

Views

3615

Build Author

Ted Moyer

Views

3615

LEAD 1515 HIGH Z MOD 4KW ER20 7.5 KW VFD

OLD Lead 1010 High Z Mod converted to Newest Lead 1515 with High Z mod, slimmer cbeam motor mounts, thrust bearings etc. Extended by original table out and upgraded my 1.5kw VFD and Spindle to 4kw ER20 Spindle and 7.5kw GT VFD

Build Author

boutrous

Views

7350

Build Author

boutrous

Views

7350

Laser Rotary Attachment

Build Summary updated after parts list completed

Fixed Gantry Easy Assembly

Fixed Gantry CNC with good accuracy and rigidity but for a higher price than the usual CNC's on the site.

CoreXY W/ Fixed Build Plate & Enclosure

Building a Core XY printer with a fixed build plate from off the shelf parts.

Build Author

sausagePaws

Views

1741212

Build Author

sausagePaws

Views

1741212

DIY Embroidery Machine V2

My second attempt at an affordable sewing machine embroidery add on. This one uses readily available electronics modules and 3D printable parts where possible.

3D printer for printing Clay/Paste

I designed this 3D printer from scratch for my mechanical engineering capstone project. It's made for printing clay but should be able to print any paste material. The clay extruder system could be easily modified to work with almost any 3D printer. The printer is approximately the same size as an Ender 3.

Build Author

Jason @ MCC

Views

8929

Build Author

Jason @ MCC

Views

8929

QueenBee Pro CNC Router and Lathe

A 1000x1500mm QueenBee Pro with a 4th Axis Rotary attachment/Lathe Bed.

Build Author

nc3dpw

Views

20314

Build Author

nc3dpw

Views

20314

(Portable) Large Format 3d Printer 4ft square frame. Build Volume 36in x 36in x 36in

Large format printer build based off successful small Corexy. I figured it could be scaled to large format and be portable. Portable meaning by removing a few pieces it could effectively be rotated out of a standard door frame.

Build Author

JCPhlux

Views

23913

Build Author

JCPhlux

Views

23913

Tesseract

Large Core XY 3d Printer W/fixed build plate

Build Author

ahayden

Views

24851

Build Author

ahayden

Views

24851

C-Beam Prefab Untitled

The C-Beam Prefab Untitled is designed as the cartesian compliment to the C-Beam XL. With the exception of requiring a couple more 1000mm C-Beams and lead screws, the build requires a minimum of additional parts. The primary intention of the build is to maximize the cutting envelope while still staying within the sweet spot for C-beam rigidity. This design can easily be modified and allows for further custom structural components to be cut with the initial build platform.

Build Author

Indieflow

Views

109300

Build Author

Indieflow

Views

109300

Indie i2

A lightweight, portable, accurate 3D Printer that has a good sized print area and small overall footprint that is easy to build, with easy to source components. The design is OpenSource allowing those with the capability to make their own parts get up and running.

Build Author

blterry1

Views

16246

Build Author

blterry1

Views

16246

The Beeline CNC

Here are the instructions to build the Beeline custom CNC router table.

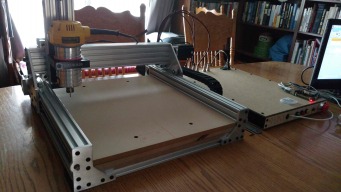

DIY CNC Machine

In this project, I show you how I built my DIY CNC machine. All moving parts of the DIY CNC router are running on ball bearings while the structural parts are made with natural materials, namely birch plywood and solid beech wood.

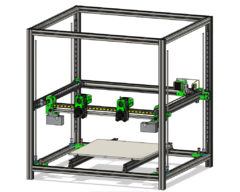

SolidCore CoreXY

All metal CoreXY 3D Printer Design with triple z, kinematic bed, and scalable corexy mechanism.

Build Author

Lindsey Lewis

Views

7664

Build Author

Lindsey Lewis

Views

7664

Update Eleksmaker with Openbuild eccentrics for X-Carriage

A simple approach to making the Eleksmaker A3 Laser build have a better functioning X-Carriage! Of course this assumes you bought an Eleksmaker A3 or plan to.

Build Author

Scott Martinez

Views

10013

Build Author

Scott Martinez

Views

10013

The Growler

This machine is a heavy duty, moving gantry style CNC router. It uses Teknic ClearPath servo motors driving ballscrews and linear rails. The machine has 36" x 48" x 19" of travel with about 7" of clearance below the gantry.

Build Author

Jay Almers

Views

6230

Build Author

Jay Almers

Views

6230

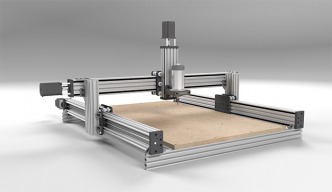

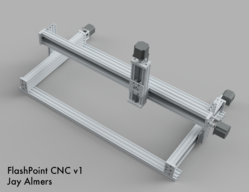

FlashPoint CNC v1: 500mm x 1000mm 3-Axis CNC Router

My build is based on many different builds but pieced together into a unit specifically to suit my needs. The footprint, without motors, is around 500mm x 1000mm with a gantry height of around 250mm. I used a combination of C-Beam, for the linear transmission, and V-Slot for the base and gantry supports. Forged angle connectors were used for attachment and I utilized the C-Beam gantry cart kits with anti-backlash blocks for both Y axes, the X axis, and Z axis.

Build Author

Serge E.

Views

58772

Build Author

Serge E.

Views

58772

myOX : a 4' x 2' OX CNC with potential

This is the story of me building myOX - my version of the "ideal" OX. I want a machine which can route/mill at least 4' wide and as long as I can feed through (don't be shy, think "infinity") as well as going deep on multiple faces - manual 4th axis. I have loads of ideas to take myOX towards that goal and way beyond. Time will tell. Just follow along through this build and possibly a few others along the way ... Check out my OXCalculator : let your computer figure out your BoM

Homemade CNC

This started as an attempt to learn to weld and quickly took on a life of its own.

Ooznest Ox with 3D Printed Gantry Plates

Ooznest Ox with gantry plates and end caps 3D printed in ABS rather than aluminum.

The RAT. A form ply and aluminium hybrid.

A hybrid of form ply and aluminium. 835x1260x100mm working envelope.

Build Author

Dave420

Views

12947

Build Author

Dave420

Views

12947

OpenBuilds C-beam 15mm belt on 1500mm C-Beam.

OpenBuilds C-beam 15mm belt on 1500mm C-Beam.

Build Author

BeTrue3D

Views

19850

Build Author

BeTrue3D

Views

19850

BeTrue3D Printer

High Quality CoreXY with focus on quality and optimized printarea versus physical size of the printer.

M10CUBE PICO CNC. A Universal Controller

An attempt is to be a Unified Modular Controller based on M10CUBE platform. For GRBLHAL and MARLINHAL applications. HAL porting is under way 1 - WIZnet Pico Clone W5100S-EVB-Pico 2 v- 6 X StepStick. Not sure about the sixth driver, (Pico pins limitation) . External connectors for larger drivers 3 - Opto - isolated spindle PWM. 4 - HMI 5 - I/O on diferent modules and Ethernet 10MBPS communication. Patches will be written to GRBLHAL for Ethernet I/Os (Interrupted).

Build Author

Edgar Mata

Views

18877

Build Author

Edgar Mata

Views

18877

ME - Core XY 3d printer

I wanted to make my own Voron, so I made my own Voron,

Build Author

Mark Carew

Views

118828

Build Author

Mark Carew

Views

118828

V-Slot® NEMA 17 Linear Actuator (Belt Driven)

Quick and Simple V-Slot Gantry System. This example build shows how easy it is to make a linear actuator using a few OpenBuilds Parts. You can mount this system an many ways so be sure to download the example models.

Build Author

Savvas

Views

18008

Build Author

Savvas

Views

18008

C-Beam Lead Screw CNC Mountain

I’m making a desktop CNC machine based on the C-Beam platform. It will be driven by Tr8 Lead Screws, and initially made from 12mm birch ply plates.

Build Author

T4Concepts

Views

70320

Build Author

T4Concepts

Views

70320

WorkBee CNC build - My honest opinion, tips and help

My main goal for my build is to have a machine that is capable of profiling and help me in my designs, for the manufacture of custom automotive headlights.

Build Author

Glenn Weston

Views

9194

Build Author

Glenn Weston

Views

9194

"AcroCadabra" My Acro Laser built with my C-Beam XL

Well I built a C-Beam XL around a year ago, I am still learning things as I make stuff with it, it has been quite a wonderful learning experience. Now I have gained enough confidence and knowhow to Mill the required Plates to build an Acro Laser System using the Acro Laser Sketchup Model. I have pulled the Model apart in Sketchup, isolated the Plates and generated the G-Code to cut/Mill the plates. I have used Sketchucam to generate the G-Code. I Use Mach3 on my C-Beam XL to Mill.

Draw bot core xy

In the design stage. Help guide.

Build Author

Shaun Weitzel

Views

4653

Build Author

Shaun Weitzel

Views

4653

OpenBuilds Lead 1515

First build of a Lead 1515!

Build Author

Keith Davis

Views

8264

Build Author

Keith Davis

Views

8264

Upgrading Your 3D Printer With Synchronous Leveling

Upgrading printers for Synchronous Leveling

cera.tops Clay 3d Printer

This 3d printer framework was designed for use with the ceraStruder clay 3D printing extruder. More info coming soon.

Build Author

Martin.Barfoed

Views

4888

Build Author

Martin.Barfoed

Views

4888

40x40 V-Slot Rod Type Linear Actuator

A Rod-type Linear Actuator based on the 40x40 V-slot profile

Build Author

Robert Hummel

Views

149111

Build Author

Robert Hummel

Views

149111

Laser V

With such great success/attention my laser got, I ended up with a good friend that would like to dabble in stencil art and so I have decided to share my build with him and you here :) I will be using all the same electronics as in my previous build except the driver boards I will be using are the famous reprap 4988's they are more easy to come by and cost less. I will also be using open builds mini v wheels/v groove extrusion just so I can get a feel for their versatile products

Build Author

shanehooper

Views

12194

Build Author

shanehooper

Views

12194

SolidCore CoreXY 3D Printer

Modular and Scalable CoreXY Printer with all metal parts.

Build Author

Michael.M

Views

60408

Build Author

Michael.M

Views

60408

GRANITE 1.0

This machine has been in the works for quite a while. Most of the plates were cut with my Shpinx machine. I have a lot more photos and information to share soon.

Build Author

crypt-tek

Views

32051

Build Author

crypt-tek

Views

32051

C3DO

My first 3D printer build. It is almost complete and will be posting the first completed print shortly. I still need to mount the print spools and a couple other odd ends to complete this.

Build Author

Mike Campbell

Views

9018

Build Author

Mike Campbell

Views

9018

bor 454-D

A large format, modular, rack and pinion build designed around OpenBuilds components.

Build Author

Keith Davis

Views

28616

Build Author

Keith Davis

Views

28616

OpenXY

Combines the layout factor of a CoreXY while using Cartesian logic. The design has a fixed build plate - moving an X/Y frame on the Z axis enclosed by an outer main frame.

Build Author

SOA

Views

57611

Build Author

SOA

Views

57611

GridBot Two: Powerfully Simple

Core XY, sensor-less homing, integrated camera, touch screen, pi, 32-bit controller, fast, quiet, beautiful prints. 300 x 300 x any build volume. Just change out the Z lead screws, rods, and four pillars. Total BOM around $700 USD. Build time around 6 hours.

Build Author

Tom Dirriwachter

Views

6301

Build Author

Tom Dirriwachter

Views

6301

3DS Cube 3 Modular Extruder

How to modularize the 3D Systems Cube 3 extruder nozzle.

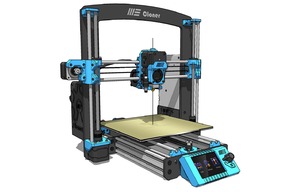

ME - Cloner 3d printer

I decided to start designing this printer, this will be my solution for a more rugged printer that you can use as workhorses...

All Metal - CoreXY Motion

Stacked CoreXY Motion System using only Openbuilds components

Build Author

Yoshiya Arii

Views

38640

Build Author

Yoshiya Arii

Views

38640

V-Slot Laser cutter and engraver

The Smart Laser Mini is an open source such as use Raspberry pi. Easy to assemble type of desktop laser cutter and engraver. Also we used V-slot

ME-Mini 3D Printer

Prusa mini inspired 3d printer

Build Author

Kyo

Views

13991

Build Author

Kyo

Views

13991

Stinger Laser

3-Axis CNC Laser Engraver running grbl 1.1 in laser mode and Laserweb4.

First CNC Router

My very first CNC Router build. It's completely scratch built.

Build Author

Paul Amelang

Views

3531

Build Author

Paul Amelang

Views

3531

4x8 CNC Router for Composites

Router for making plugs for composite part production, and for cutting CFRP.

Build Author

lekey

Views

6313

Build Author

lekey

Views

6313

Modular Desktop Vacuum Former

This is a small desktop vacuum former that can be connected to a shop-vac and an electric heat source (like a grill for instance). You can control the time each appliance stays turned on, and the vacuum is automatically turned on when the tray is placed on top of the model. The vacuum table is 20x20cm wide, and I've tested it mostly with 1mm thick PET sheets.

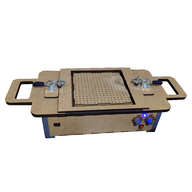

DIY Vacuum Hold Down table

A simple vacuum hold down/clamp set up using a 6hp canister vacuum.

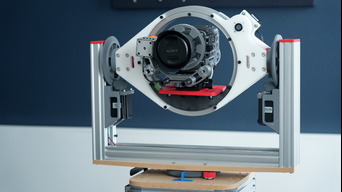

6 Axis Motion Control Camera Rig (PAN, TILT, ROLL, SLIDE, FOCUS, ZOOM)

6 axis rig based on OpenBuild C-Beam and ESP32 MCU, WiFi controlled with custom app.

Build Author

Srđan Marković

Views

3130

Build Author

Srđan Marković

Views

3130

Second machine

Machine with 12,5Nm closed loop steppers or servo steppers

Corexy laser

I have tested my Opt Lasers laser module on a "open" frame for some time. Decided that I want to test a corexy setup and combine it with a boxed/enclosed design - my goal is to get high precision + a safe setup with protection from the laser light + a fan to extract the smoke/exhaust..

HD CNC

Heavy Duty build with 1605 Ballscrew and Linear Rail

Some Improvements on the Workbee 1000x1000

Improvements both real and suggested for the Workbee assembly

Z-Axis for Laser Diode

Custom Z Axis for OptLaser 6watt and the Acro System

Build Author

Kyo

Views

137946

Build Author

Kyo

Views

137946

C-beam Sphinx

A strong desktop cnc router that will enable you to make larger aluminium plates without taking up to much room. Simple, strong and opensource ! Build one today..

Gigantesque CNC

This is a upgrade to make a little deeper and a little bigger foot print for cutting. This is a copy of design off Rob Taylor idea for Dbl C Beam setup. The goal though is to design it around a new build with minimal tools for some one with no cnc access. Drillpress and drill bits and tap set. A 10in Non ferrous metal cutting blade for my table saw. Paper printer for printing DXF files.

Build Author

Troy Joachim

Views

13450

Build Author

Troy Joachim

Views

13450

Sigron IDEX

BNC3D Signax + Voron = Sigron IDEX

Build Author

RSch

Views

3037

Build Author

RSch

Views

3037

Scroll-saw Spiral Cutter

Attached to a scroll saw you can cut nested wooden spirals with this jig. Make two, three, four ... interlocking spirals that unwind/unscrew. Fascinating toys or art objects!

Rotary axis for Workbee

Adding a rotary axis to the Workbee 1010. Including height modifications to the Workbee.

Build Author

C-CNC

Views

12188

Build Author

C-CNC

Views

12188

Gantry Style CNC from plywood

I am currently 15 years old, from Germany and trying to build a low budged CNC router. I only designed this CNC based on other CNC routers that I have seen and what I am able of. It consists mostly of 2.3cm plywood to keep costs down. The size of the work area is approx. 40 x 80 cm. I would be really glad if you could give me advice's for improvement on the design and everything else ... ( I could really need your help :) ) enjoy :)

Build Author

crypt-tek

Views

8776

Build Author

crypt-tek

Views

8776

crypt-cube

The crypt-cube is another project I've been working on off and on over the past year, unlike my previous built C3DO this is a much smaller built with a volume of 318mm x 240mm x 220mm. With this build my main focus is precision and speed.

Build Author

Mark Carew

Views

12323

Build Author

Mark Carew

Views

12323

NEMA 17 Belt and Pinion Actuator

This Belt and Pinion actuator is a great example of how easy it is to convert your machine into a belt drive system.

Plastic Monstrosity

Large inexpensive build that can cut a 4x8 ft sheet with room to spare. Can be built using only a 3D printer and standard parts -- no special CNC'd plates required.

TITANXY (Fixed Build Plate, Quad Z Screw, CoreXY)

Super Rigid CoreXY 3D Printer