Build List

-

Active Filters:

m

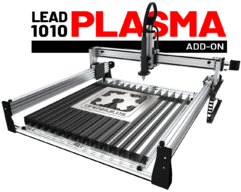

LEAD 1010 PLASMA Add-On

LEAD 1010 PLASMA Add-On is a great modification you can do for your LEAD 1010 to convert it into a metal cutting monster machine!

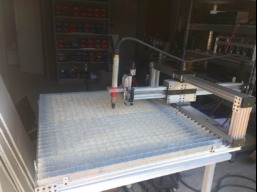

Dragon Plasma cutter

Inspired by MetalGuru's idea : The plasma too cutter . If you have to cut small to medium sheet of steel with a plasma , this build may be for you

Build Author

OpenBuilds

Views

17332

Build Author

OpenBuilds

Views

17332

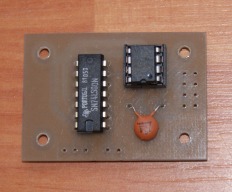

BlackBox X32

The next level of CNC motion control solutions. Packed with advanced new features and built on the reliability of the proven BlackBox system

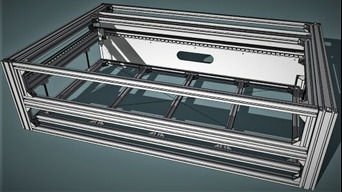

2 GANTRY CNC HOTWIRE MACHINE

A 2 independent gantry affordable hotwire machine.

Sphinx 66

A Sphinx Linear rail build (600mm x 600mm) hence the title Sphinx66. Plates supplied by Chris Laidlaw. Linear rails used MGN15

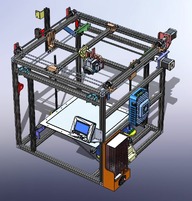

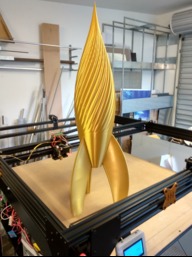

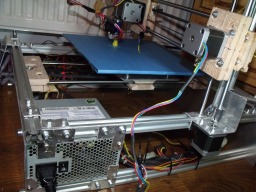

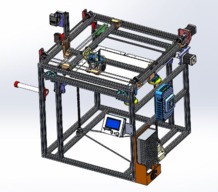

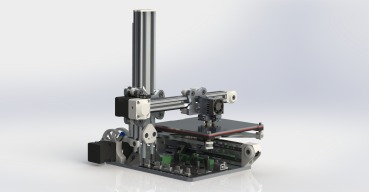

Dash X Direct, Cross-Beam 3d Printer

This is the next version of Dash, now operating much closer to its potential. Please message me if you need anything, such as Simplify3D settings, material information, design intent etc. Since the Pack-and-Go zip file is fairly large (120mB), here is a link where it can be downloaded: https://drive.google.com/file/d/1Q3ygyo_tTrB4UYIV62_wtCSCbWuE3krT/view?usp=sharing Note: I use Solidworks 2022, acquired through their Solidworks for Makers program (check it out!). A super deal at $100/yr

Build Author

Neil Rosenberg

Views

35011

Build Author

Neil Rosenberg

Views

35011

Dash-X 3D Printer: Innovative design

Cross-beam Cartesian 3d printer with dual master/slave lightweight fiberglass drive shafts, BMG style extruder with Bowden (Capricorn) tubing. Hot end is Creality Ender 3 style with two fans and BLTouch for autoleveling. Filament runout sensor is also included.

Build Author

Retsaj

Views

51012

Build Author

Retsaj

Views

51012

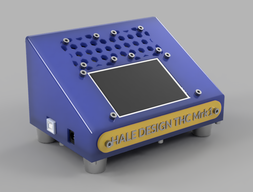

Standalone Torch Height Controller for CNC Plasma Cutting

A Torch Height Controller helps improve plasma cut quality and can save a CNC Machine from crashing. This design doesn't require you to know electronics or need any custom circuits... Its plug and play! This is a COMPLETELY standalone controller with a built-in Driver powerful enough to run just about any stepper motor. (maybe a little to powerful for a NEMA17)

Build Author

Michael.M

Views

35356

Build Author

Michael.M

Views

35356

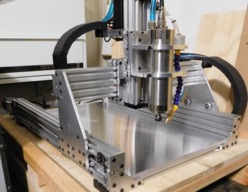

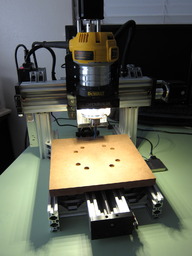

7050 Sphinx

This is a Kyo Sphinx CNC Router build. Working Area: 350mm X 500mm Link to original design: https://openbuilds.com/builds/c-beam-sphinx.3605/

C-beam Machine - Modesty

Modified C-beam Machine. Taller (30 cm) C-beam uprights in gantry, and longer 750 mm frame in Y direction. XL gantry plate on X (and Z?). Y will have additional 700 mm SBR16 rails as extra support and slightly raised bed to fit above stepper motor. Approx. machinable area of 370 x 370 mm.

Build Author

Mark Carew

Views

18643

Build Author

Mark Carew

Views

18643

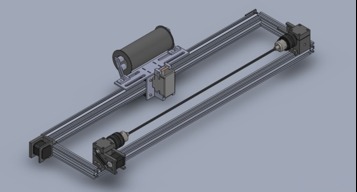

V-Slot™ Nema 23 Linear Actuator (Belt Driven)

This example build shows how easy it is to make a linear actuator using a few OpenBuilds Parts.

Large 'Double H-Bot' using Openbuilds 2040 v-slot

The aim of this design is to build a simple, cost effective (under $1000) and relatively compact large volume (m3) 3D printer that will use a pellet extruder to create art/design objects using shredded recycled plastics.

Build Author

OpenBuilds

Views

22300

Build Author

OpenBuilds

Views

22300

INTERFACE CNC Touch Control System

Super cool standalone Human-Machine Interface for controlling your CNC machines!

Build Author

EvanH

Views

827

Build Author

EvanH

Views

827

"Hawk" Heavy-duty dual-Z pseudo C-Beam

A compact, strong machine with very high Z clearance, yet can still mill aluminium easily.

Lead 1515 tilting table and vertical table accessory

I wanted a CNC machine that was able to do dovetails and other box joints. I also wanted to have it be able to tilt so it would take up less space when I was working on other projects.

5'x10' CNC Plasma/Mill Table

Plasma Mill CNC

HYDRA multi tool CNC , based on ACRO

modifying ACRO

Z Floating Head

It's a Z floating head idea. Works well. Recommend cleaning the inside of your holes well with Q tips, and polishing the 1/4-20 bolts with car wax and you won't need oil as it slides perfectly. Hope this helps

KRE CO2 2x4 Laser

Large Format CO2 Laser Cutter

Build Author

Mark Carew

Views

73290

Build Author

Mark Carew

Views

73290

BlackBox Motion Control System

The Openbuilds BlackBox is a new system evolved around a set of subsystems that cover more than just control and also more than just CNC type applications! With a plug-and-play easy connection system this controller can be used with ease, without sacrificing power.

Build Author

Mark Carew

Views

57193

Build Author

Mark Carew

Views

57193

V-Slot NEMA 23 Linear Actuator (Lead Screw)

Learn to build a super strong nema 23 lead driven linear actuator

Build Author

Kyo

Views

21953

Build Author

Kyo

Views

21953

Sphinx 55

A Sphinx build to inspire and encourage all those who want to get started with cnc to check out Opensbuilds line of machine bundles and hardware.

Build Author

cdsmith12

Views

24212

Build Author

cdsmith12

Views

24212

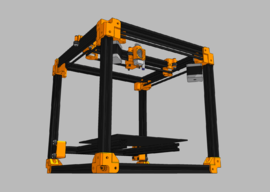

The Plastic Beast CoreXY Printer

In my opinion, this is the easiest and most complete tutorial to walk you through building a large platform 3D printer and the Sketchup File is included for you to make any changes needed.. The Plastic Beast is a CoreXY Printer with a build platform of 440mm square. You can print 600mm or about 23 inches diagonal. Any level of user from novice to expert should gain something from my tutorial.

Build Author

Troy Proffitt

Views

23545

Build Author

Troy Proffitt

Views

23545

Sphinx Upgraded plates / ballscrews and linear rail

Upgraded Sphinx Cbeam using 3/8 aluminum plates and linear rails / ballscrews

Build Author

Mark Carew

Views

116820

Build Author

Mark Carew

Views

116820

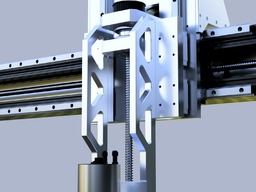

C-Beam™ Linear Actuator

Here are a few helpful C-Beam actuator ideas that will help you get a start on your builds

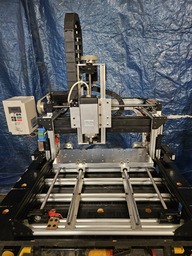

My large machine 48 X 48

This machine is controlled by a Mach3 BOB. I USED Nema 34 stepper motors and a 3kw, water cooled spindle. I’m in the process of adding a vacuum table with 4 zones. I have an X-carve so I use Easel to create G-code for the large machine. I’m currently looking for a way to stabilize the Y-axis. It wiggles a little, so I want to add another linear rail high on both sides.

Build Author

Mark Carew

Views

178070

Build Author

Mark Carew

Views

178070

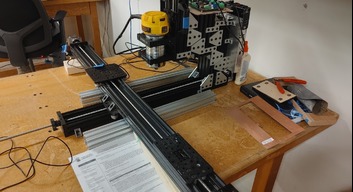

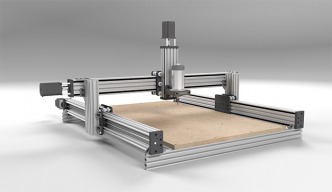

LEAD CNC 1010 (40" x 40")

The OpenBuilds Lead Machine takes us back to the roots of the OpenBuilds modular building system, and has proven itself as an adaptable design that can compete with any machine in its class!

Build Author

sausagePaws

Views

72396

Build Author

sausagePaws

Views

72396

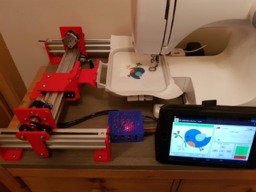

Embroidery machine with XY belt and pinion drive.

A simple Embroidery machine using an XY belt and pinion drive to drive a hoop under a standard sewing machine. Needle timing, machine power and stepper control are all provided by a PIC processor. A tablet provides the higher level formatting required for communicating with the PIC chip.

Build Author

Ryan Lock

Views

122694

Build Author

Ryan Lock

Views

122694

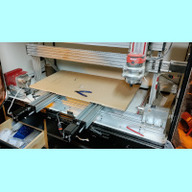

WorkBee CNC Machine

The WorkBee is our latest CNC Machine and is a culmination of all our experience, feedback, and suggestions from selling the OX CNC Machine over the past 2 years. The WorkBee is capable of accurately cutting foams, woods, plastics or aluminum at depths greater than 25mm to 0.2mm accuracy or greater.

Build Author

CONUCON

Views

2645

Build Author

CONUCON

Views

2645

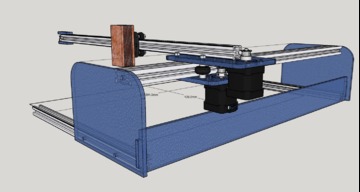

3DTwinX Gantry CNC System

Belt driven 3-axis linear system for high precision and low costs. > Threading and linear real cutting needed

Build Author

Mark Carew

Views

28106

Build Author

Mark Carew

Views

28106

High Z Mod for Lead CNC

The High Z modification for the LEAD CNC brings your creative capabilities to new heights! With 8" of clearance this modification can be adapted easily to your existing LEAD CNC Router.

Build Author

Ryan Lock

Views

128929

Build Author

Ryan Lock

Views

128929

Ooznest OX CNC Machine

The Ooznest OX CNC Machine Kit is based on the OX CNC Machine designed by Mark Carew, and it incorporates many upgrades from this community. The plate designs in our kit are based on the originals. However we have added our own touches to increase the performance and design of the machine. To complement Mark's build videos, we have made a complete written instruction manual, with IKEA'eske assembly diagrams.

Heavy Metal

CNC Mill built for cutting metal.

Build Author

Gerald Klein

Views

13183

Build Author

Gerald Klein

Views

13183

300mm Diameter, 1 Meter tall, Delta 3d Printer

I built a custom delta using 3, 1000 mm long C-Beam® Linear Rails and 3 C-Beam Gantry Sets. I had the bottom and top plates water jetted ( for accuracy ) out of 1/2 inch aluminum, from a design that I did in Fusion 360.

Reworked Sepcraft 420 CK

Its alive !

Salmon Sphinx 1.0

A tribute build based on Kyo's wonderful CBeam Sphinx. My hope is to improve on that build slightly, but to be honest, I'll probably just screw it up. I'll use this build to publicly document my failures.

Build Author

Suhmanda

Views

1972

Build Author

Suhmanda

Views

1972

DIY CNC SPINDLE

CNC SPINDLE FOR DIY ROUTERS AND MILLING MACHINES ITSRS-985 MOTOR HAS MUCH BEFINITS THAN ANY OTHER DC MOTOR IN MARKET

Build Author

alan richard

Views

45141

Build Author

alan richard

Views

45141

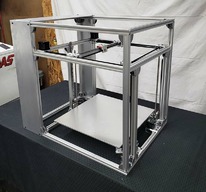

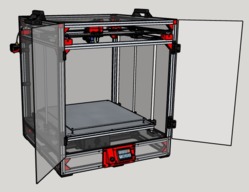

Core-XY Cube

An enclosed cube shaped 3D printer using CoreXY motion. Fabricated from V slot extrusion, standard extrusion, aluminium plate and acrylic sheet using basic workshop tools. Using standard RAMPS/ Reprap electronics. Technically a 'Repstrap' currently used to build a true 'Reprap'

Build Author

Rob Taylor

Views

15521

Build Author

Rob Taylor

Views

15521

M4: 1510SS Heavy Mk.I

A 1500x1200mm, 20mm rail and 1610 ballscrew, heavy-duty, four-axis gantry machine. As high speed as spindle power MRR will allow for. Approx 4 x 3 x 1ft travels, intermediate size between benchtop and floor-scale units. Aiming at $10-15k machine in the $3k region.

Software speed control of a brushless dc (Bldc) motor from Mach3.

Although this build is typically Mach3 related there is no reason it cannot be adapted for use with any machine control software which provides a PWM spindle control output. As an addition, an option has now been added which will enable the interface to manually control outrunner speed without the need for a PWM signal.

Plasma Table 006

Fast, inexpensive, near-zero maintenance, and 2+ years of near-daily use.

Build Author

Mark Carew

Views

252135

Build Author

Mark Carew

Views

252135

C-Beam® Machine - Plate Maker

This C-beam Machine is an in affordable CNC plate maker and 3D carving machine!

Build Author

Mark Carew

Views

13200

Build Author

Mark Carew

Views

13200

C-Beam XLarge X/Y Table

This OpenBuilds C-Beam XLarge X/Y Table is a great display of how easy it is to modify and create awesome configurations with the OpenBuilds system!

Build Author

Ryan155

Views

8476

Build Author

Ryan155

Views

8476

RIGCNC

I made a mill from first principles because I didn't like any of the ones that were out there, More info can be found on the website RigCNC.com

Build Author

OpenBuilds

Views

12221

Build Author

OpenBuilds

Views

12221

C-Beam® Tension XL Linear Actuator

Bringing your lead screw precision and accuracy to new lengths using a simplistic tension system!

Build Author

that-jim

Views

41086

Build Author

that-jim

Views

41086

LINEAR RAIL SPHINX 55 (Blue OX plates)

Machine based on Sphinx 55 built with linear rails.

Build Author

Damian V-SLOT Poland

Views

1775

Build Author

Damian V-SLOT Poland

Views

1775

LEGO BOX

Discover our unique DIY project that blends creativity, utility, and sustainability. This guide will take you through the construction of a LEGO display box, ingeniously crafted using offcuts of V-SLOT aluminium profiles and OpenBuilds accessories. Not only is this an eco-friendly approach to reusing surplus materials, but it also results in a stylish, functional display for your prized LEGO models. Whether you're a LEGO enthusiast or have little LEGO fans at home, this innovative project offers

Build Author

OpenBuilds

Views

18190

Build Author

OpenBuilds

Views

18190

OpenBuilds Table Series

The OpenBuilds Table Series offers a modular table structure that grows with your needs.

Build Author

Mark Carew

Views

68106

Build Author

Mark Carew

Views

68106

OpenBuilds Workbee 1010 (40" x 40")

The OpenBuilds WorkBee 1010 - 1000x1000 Lead Screw Driven CNC Machine

Build Author

UltiBots

Views

34135

Build Author

UltiBots

Views

34135

UltiBots CB3030 CNC Router

The UltiBots CB3030 CNC uses C-Beam, V-Slot and an extruded aluminum T-Slot work table. This allows 6mm T-Nuts, step clamps and blocks to secure materials to the work surface. The all metal design makes the use of a mister possible.

Build Author

Yanou Fishel

Views

8021

Build Author

Yanou Fishel

Views

8021

Beefed up Minimill

A beefed up minimill, ready to gnaw on some aluminum! HG15 linear rails, a thick heavy column, bellows and easy fixturing and tramming.

C-Beam Machine XLarge

A rigid and wide format, plate and carving CNC.

Build Author

2SIsurf

Views

4235

Build Author

2SIsurf

Views

4235

Hotwire cnc Surfboards

Xl 2 axis foam cutter Eps Surfboard blanks Simple open concept but high production machine. Shape 3d case with open builds controller

Build Author

Jason Moore

Views

9904

Build Author

Jason Moore

Views

9904

Lead1500 Plasma Table w/THC

lead machine plasma table with Black Box, and Torch Height Control

Build Author

wackocrash5150

Views

16963

Build Author

wackocrash5150

Views

16963

45W CO2 Laser Build

A co2 laser build that is heavily inspired and based quite a bit off Pedro Fernandez' 50w co2 laser build. This is my first build post so, bare with me.

Monster-not-so-mini-mill

My Minimill hit the gym, and isn't so mini anymore

Custom 4x4 CNC

I started designing and ordering parts for this build back in Oct 2021. Unfortunately life got in the way and I had to sideline the project to deal with more important projects. I am now back working on this project full time. I originally was building a MPCNC on this torsion box platform I built but quickly realized how difficult it would be to produce anything with good accuracy. So I decided to design my own CNC that would be more robust and accurate.

Build Author

alex_b

Views

16417

Build Author

alex_b

Views

16417

TACIT RONIN CNC - Flood Coolant Enabled C-Beam

The TACIT RONIN CNC is a fully enclosed C-Beam platform intended for flood coolant cutting of Carbon Fiber and G10 composites.

Build Author

Mark Carew

Views

205690

Build Author

Mark Carew

Views

205690

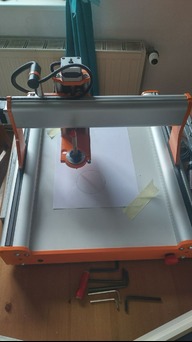

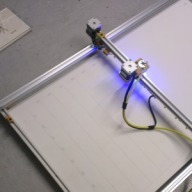

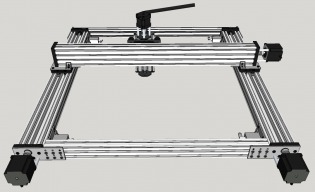

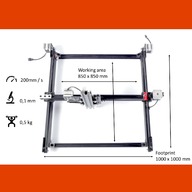

OpenBuilds ACRO System

The OpenBuilds ACRO System was developed to be the most accurate and cost effective positioning system in its class. The ACRO System incorporates the OpenBuilds V-Slot system and, therefore, has the unique ability to expand to multiple sizes creating a size configuration custom to your needs. Choose the size that best fits your workshop. This versatile system allows for precise positioning of many different mountable tools and attachments.

Much4 - LaserV printed version

By following the way of Robert Hummel, I drew a version of its exellent Laser V to use NEMA17 and easily printable parts.

Build Author

Cam Garrett

Views

2158

Build Author

Cam Garrett

Views

2158

Sturdy Motorized Photographic Copy Stand

i would like to build a sturdy motorized photographic copy stand. i have hobbled together a hand crank version using a used umbrella pole but it is not suitable as it is awkward and wobbly.

Build Author

OpenBuilds

Views

3205

Build Author

OpenBuilds

Views

3205

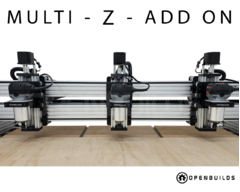

Multi Z LEAD Machine Addon

The Multi Z adds multiple Z axis to a LEAD CNC Machine allowing it to cut and carve 2 to 3 times the amount of projects in the tame it takes to make just one

Photogrammetry 3d Scanner

A mid-sized version of a Photogrammetry 3D Scanner.

Build Author

Mark Carew

Views

1156268

Build Author

Mark Carew

Views

1156268

OpenBuilds OX CNC Machine

OpenBuilds OX CNC Machine. A strong easy to build shop CNC router that can be sized to suit your needs. Many new features have been incorporated into the OX to make it a great router that is sure to inspire!

Build Author

deltajegga

Views

8207

Build Author

deltajegga

Views

8207

THE delta

probably as big as you'd want it...

Build Author

Ted Moyer

Views

3617

Build Author

Ted Moyer

Views

3617

LEAD 1515 HIGH Z MOD 4KW ER20 7.5 KW VFD

OLD Lead 1010 High Z Mod converted to Newest Lead 1515 with High Z mod, slimmer cbeam motor mounts, thrust bearings etc. Extended by original table out and upgraded my 1.5kw VFD and Spindle to 4kw ER20 Spindle and 7.5kw GT VFD

Filament winder ( carbon fiber )

Carbon fiber filament winder

Y table for LEAD Lathe - essentially a High Z Cbeam XL

I built the lathe as a dedicated rotary axis, but I soon realized I could have a back up CNC for very little expense.

Build Author

Sonny Lowe

Views

5157

Build Author

Sonny Lowe

Views

5157

MakerSL MSL-65 Manual Coffee Grinder Stand

I know this build is a little off category here at OB, but I wanted to share it with the community (as well as other coffee lovers) and show however vast the possibilities are when OB hardware is involved. This is a powered stand intended to operate a manual coffee grinder. It is compact, light, portable and uses simple drive components (B&D Cordless Screwdriver). I will post two version, V-1 (Beginner skill level ) and V-2 (Intermediate skill level). Both accomplish the same results.

Sphinx 55 on MGN12 linear rails

My machine is a combination of the Openbuilds Sphinx 55, MGN12 linear rails knockoffs and custom made plates made by Chris Laidlaw

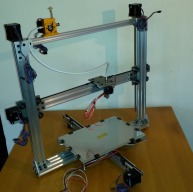

My 3D Printer

A DIY 3D printer. At beginning made from aluminium profiles, aluminium sheet and wood :)

THE BIG GREEN MACHINE

1500*1500*1900 (xyz) Biocomposite Pellet 3D printer

Build Author

sausagePaws

Views

1741217

Build Author

sausagePaws

Views

1741217

DIY Embroidery Machine V2

My second attempt at an affordable sewing machine embroidery add on. This one uses readily available electronics modules and 3D printable parts where possible.

Build Author

nc3dpw

Views

20317

Build Author

nc3dpw

Views

20317

(Portable) Large Format 3d Printer 4ft square frame. Build Volume 36in x 36in x 36in

Large format printer build based off successful small Corexy. I figured it could be scaled to large format and be portable. Portable meaning by removing a few pieces it could effectively be rotated out of a standard door frame.

Build Author

Rick 2.0

Views

14508

Build Author

Rick 2.0

Views

14508

C-Beam Mini Mite

A small system with a big bite. Design achieves a good balance between machine size vs. build area, rigidity and ease of construction all while keeping build cost as low as possible.

Build Author

BNMaker

Views

9697

Build Author

BNMaker

Views

9697

+Laser

A minimalist 2-axis A2 sized laser diode cutter/engraver. Designed to give the most function using the very least number of parts at the lowest price.

Dragon Portable CNC Plasma Cutter

A small portable CNC Plasma Cutter with some unique features

Build Author

viktop

Views

20855

Build Author

viktop

Views

20855

Simple Cnc System (arduino Grbl)

Arduino powered simple CNC system using GRBL firmware. Designed to give the most function using the very least number of parts at the lowest price.

Build Author

ahayden

Views

24854

Build Author

ahayden

Views

24854

C-Beam Prefab Untitled

The C-Beam Prefab Untitled is designed as the cartesian compliment to the C-Beam XL. With the exception of requiring a couple more 1000mm C-Beams and lead screws, the build requires a minimum of additional parts. The primary intention of the build is to maximize the cutting envelope while still staying within the sweet spot for C-beam rigidity. This design can easily be modified and allows for further custom structural components to be cut with the initial build platform.

C-beam charmer

Double C-beam Y axis 500mm., Double 2080 X axis 600mm. , C-beam Z axis 250mm, TB-6600 drivers, MKS-DLC32v2 GRBL w/wi-fi and blue tooth

Remote Toiler Flusher!

This project provides an easy method for my granddaughter to use the facilities in the smallest room of the house! The toilet cistern is located in the garage and was originally manually activated by a pushbutton connected via a cable. The location of the pushbutton - combined with the stiffness of the mechanism made it tricky for her to use. This project provides a solution to the problem.

Build Author

Indieflow

Views

109303

Build Author

Indieflow

Views

109303

Indie i2

A lightweight, portable, accurate 3D Printer that has a good sized print area and small overall footprint that is easy to build, with easy to source components. The design is OpenSource allowing those with the capability to make their own parts get up and running.

Build Author

James Archer

Views

11929

Build Author

James Archer

Views

11929

Archer - An extendable all metal 3D printer

This is an all metal build using OpenBuilds V-Slot linear rails to produce a high quality and cost effective 3D printer. The printer is designed to be scalable for your desired build area and can utilize high quality hotends with 16mm groove mounts such as E3D.

Desktop CNC

A desktop Cartesian CNC router

Build Author

OpenBuilds

Views

8735

Build Author

OpenBuilds

Views

8735

Swing Arm

Simple Swing Arm Build for the Modular Table Series. Create a simple vacuum swing arm that swings over your machine keeping your vacuum hose and router cord, etc. up and out of the way

Build Author

mytechno3d

Views

12708

Build Author

mytechno3d

Views

12708

Z FLoating head for Plasma cutting (OX CNC compatible)

How to convert your OX CNC to a plasma cutter at low cost

W|W plasma/drag knife 1500x1500 (floating head & z-axis)

Step by step designing and implementing of my plasma approach

Build Author

Ahmed Ibrahim

Views

6273

Build Author

Ahmed Ibrahim

Views

6273

Cairo Mini 3d-Printer

We are introducing the Cairo Mini 3d-printer! It’s a DIY fully Open-source Reproducible 20x20cm 3d-printer. The original goal of the Cairo Mini 3d-printer is to create a low-cost 3d-printer below 220$(3500 LE). That anyone can build with ease.

Build Author

Leonard Cross

Views

33511

Build Author

Leonard Cross

Views

33511

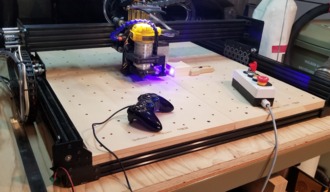

Workbee CNC Router/Laser/Plotter

A CNC machine with an expansive 30x30" work area, supporing a router, laser, simple plotting and work monitoring camera. Control includes a tethered control box, game controller style jog control, and relay controlled AC outlets for all appliances. Accessories include a 3D printed dust shoe, a complete spoilboard and hold down system, an XYZ touch probe and multiple vacuum retention boards to support full profile routing.

Build Author

blterry1

Views

16248

Build Author

blterry1

Views

16248

The Beeline CNC

Here are the instructions to build the Beeline custom CNC router table.

V-Slot Miter Saw Stop

A quick and simple saw stop build.

DIY CNC Machine

In this project, I show you how I built my DIY CNC machine. All moving parts of the DIY CNC router are running on ball bearings while the structural parts are made with natural materials, namely birch plywood and solid beech wood.

SolidCore CoreXY

All metal CoreXY 3D Printer Design with triple z, kinematic bed, and scalable corexy mechanism.

Build Author

Damian V-SLOT Poland

Views

13889

Build Author

Damian V-SLOT Poland

Views

13889

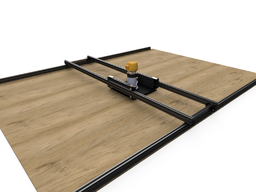

DIY Slab Flattening Mill

V-SLOT profiles and OpenBuilds accessories give us many possibilities. We decided to build a manual ROUTER SLED using only components of the OpenBuilds system. The design is simple to build, construction takes little time, and the frame is easy to transport.

Build Author

Lindsey Lewis

Views

7665

Build Author

Lindsey Lewis

Views

7665

Update Eleksmaker with Openbuild eccentrics for X-Carriage

A simple approach to making the Eleksmaker A3 Laser build have a better functioning X-Carriage! Of course this assumes you bought an Eleksmaker A3 or plan to.

My Openbuilds Journey

I've learned a lot from building this machine, and had and will continue to enjoy using it. Let The CHIPS FLY!

Build Author

Jay Almers

Views

6230

Build Author

Jay Almers

Views

6230

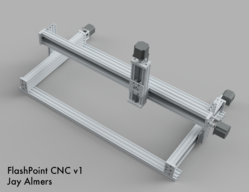

FlashPoint CNC v1: 500mm x 1000mm 3-Axis CNC Router

My build is based on many different builds but pieced together into a unit specifically to suit my needs. The footprint, without motors, is around 500mm x 1000mm with a gantry height of around 250mm. I used a combination of C-Beam, for the linear transmission, and V-Slot for the base and gantry supports. Forged angle connectors were used for attachment and I utilized the C-Beam gantry cart kits with anti-backlash blocks for both Y axes, the X axis, and Z axis.

Build Author

Serge E.

Views

58774

Build Author

Serge E.

Views

58774

myOX : a 4' x 2' OX CNC with potential

This is the story of me building myOX - my version of the "ideal" OX. I want a machine which can route/mill at least 4' wide and as long as I can feed through (don't be shy, think "infinity") as well as going deep on multiple faces - manual 4th axis. I have loads of ideas to take myOX towards that goal and way beyond. Time will tell. Just follow along through this build and possibly a few others along the way ... Check out my OXCalculator : let your computer figure out your BoM

C-Beam XXLarge "Tank"

This is a modified build C-Beam XLarge. 1000mm C-Beam used for X and Y axis, and the Y Axis moves the X bridge, not the material being worked.