Build List

-

Active Filters:

d

Build Author

BinaryConstruct

Views

9018

Build Author

BinaryConstruct

Views

9018

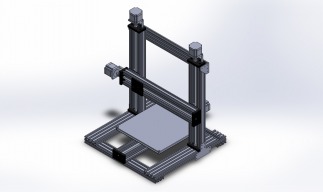

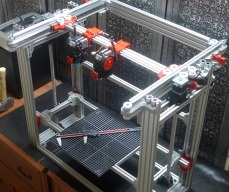

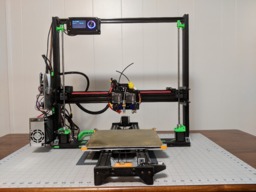

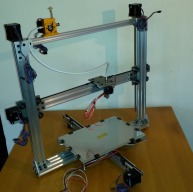

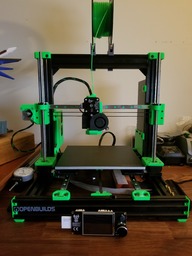

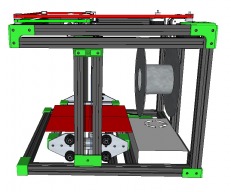

BinaryConstruct V3

This printer is a design that has evolved over three years. The original goals of this project were to design a rigid printer that had a large print volume, 300mm^3, with easily sources parts and a minimum of complicated printed parts.

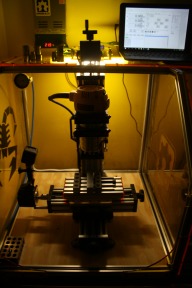

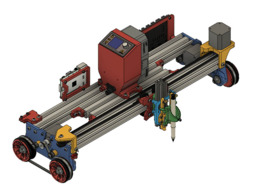

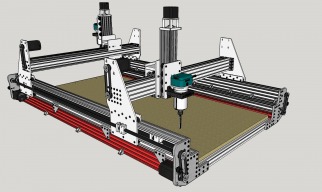

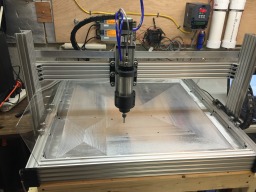

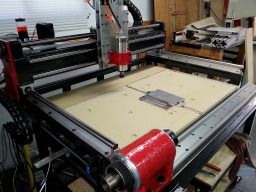

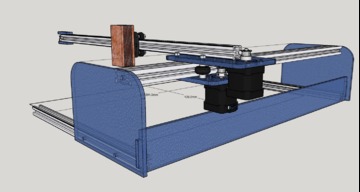

YAPCNC (Yet Another Poor's Man CNC)

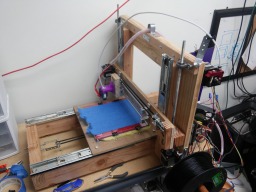

Yet Another Poor's Man CNC (YAPCNC) is my first attempt to build a CNC. The idea is for the build to be as inexpensive as posible while being usable for my goals.

Build Author

Andreas Bockert

Views

10494

Build Author

Andreas Bockert

Views

10494

Sphinx Z-axis upgrade

Upgraded Z-axis for Sphinx-style CNC using ball screws and linear rails.

Build Author

Spark Concepts

Views

4369

Build Author

Spark Concepts

Views

4369

MPG Jog Controller for CNC xPRO

Been playing around with an MPG Jogwheel

Build Author

crypt-tek

Views

8894

Build Author

crypt-tek

Views

8894

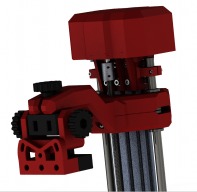

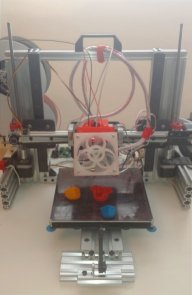

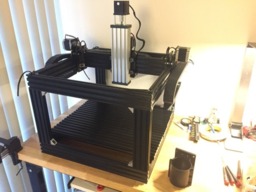

crypt-cube

The crypt-cube is another project I've been working on off and on over the past year, unlike my previous built C3DO this is a much smaller built with a volume of 318mm x 240mm x 220mm. With this build my main focus is precision and speed.

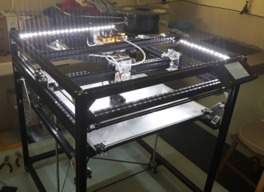

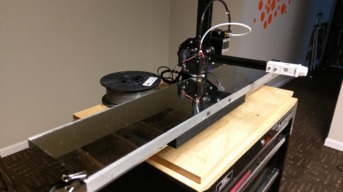

18x36x16 Inch 3D Printer - Work in progress

Tough 3D Printer using OpenBuilds Parts!

Build Author

Kyo

Views

22623

Build Author

Kyo

Views

22623

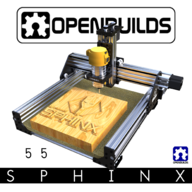

Sphinx 55

A Sphinx build to inspire and encourage all those who want to get started with cnc to check out Opensbuilds line of machine bundles and hardware.

Gigantesque CNC

This is a upgrade to make a little deeper and a little bigger foot print for cutting. This is a copy of design off Rob Taylor idea for Dbl C Beam setup. The goal though is to design it around a new build with minimal tools for some one with no cnc access. Drillpress and drill bits and tap set. A 10in Non ferrous metal cutting blade for my table saw. Paper printer for printing DXF files.

Build Author

Scott Drake

Views

15192

Build Author

Scott Drake

Views

15192

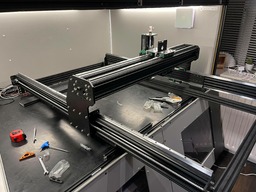

1500x1000 CNC Router

1500x1000, additional frame stiffening from laser cut Stainless steel bracing plates, Nema 34 motor upgrade and Hiwin 16mm ballscrew additions on the way. Ethernet Smooth stepper control, 2.2kw Water cooled spindle. Schneider atv320 variable speed drive. SICK inductive limit switches, Leadshine Em882S stepper drivers ,1kw 62V supply for Stepper drives

Build Author

Ryan155

Views

9053

Build Author

Ryan155

Views

9053

RIGCNC

I made a mill from first principles because I didn't like any of the ones that were out there, More info can be found on the website RigCNC.com

Build Author

AK-Creation

Views

21095

Build Author

AK-Creation

Views

21095

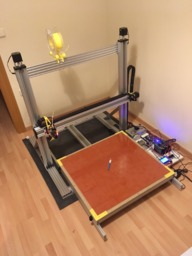

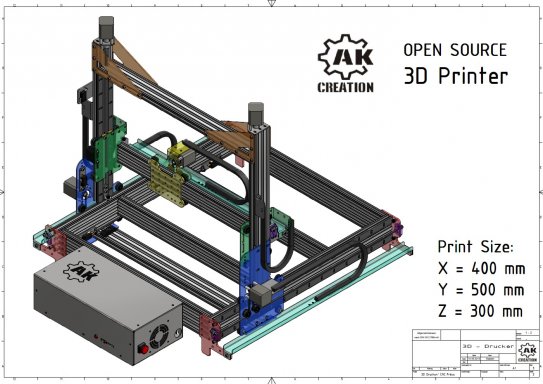

3D Printer - Big Size

I creat a open source 3D Printer to print big things. Print size: 400x500x300 mm. You can download the Drawing in PDF and in Inventor 2013 format. The unwinding drawings are also included. I take some detail photos for a better understanding.

Build Author

pdesigns

Views

27648

Build Author

pdesigns

Views

27648

RepRap Tuga

This is a work in progress(not printing yet). Expect this instructions to grow with time, but for now it is mainly interesting for those who want to take part in developing this printer.

Build Author

Sheepdog

Views

25330

Build Author

Sheepdog

Views

25330

Griffin Delta Printer

Designed from the ground up as a low cost, highly scalable delta printer. This printer has been built as small as carry on luggage size, up to an 18in wide print surface and is capable of larger. Approximate cost is low to mid $500 range start to finish, including electronics for a basic model.

Build Author

Mark Carew

Views

102423

Build Author

Mark Carew

Views

102423

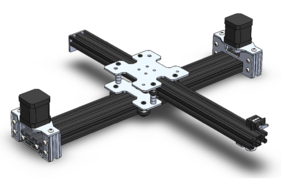

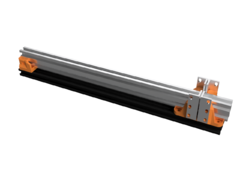

V-Slot® NEMA 17 Linear Actuator Bundle (Lead Screw)

Example model of lead screw driven actuators for your next project!

Build Author

M^3

Views

20506

Build Author

M^3

Views

20506

M Cubed CNC Mill

A no-nonsense CNC mini mill to get the job done.

CNC Jr.

A small, quiet and clean desktop CNC designed for fine cutting.

kukatype 3d printer open source

im just starting and the size of this is 1.5 meter from base to end

Build Author

Hytech2k

Views

32589

Build Author

Hytech2k

Views

32589

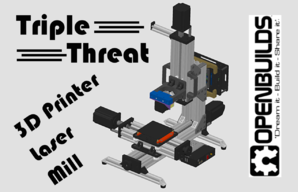

Triple Shot R-P-M Area 51 CNC Parts

We wanted to create a rapid prototyping machine with excellent 3D printing, laser cutting and engraving, and light CNC router work capabilities.

BAFP 3D Printer

A New Core XY Printer build. BAFP stands for Big And Fast Printer. It will be awesome !!

Roberta Clementine

The Roberta Clementine a proof of concept and progenitor to the series of printers I will be calling the Clementine Sisters. The printer is named after Pittsburgh Pirates baseball player Roberto Clemente. Although it is more accurate to say the printer is named after the school I work for which is named after Clemente the Roberto Clemente Charter School. http://www.myrccs.com Roberta is the first and not really built to last but instead built to test ideas and to produce the parts for successors

Build Author

James Archer

Views

12190

Build Author

James Archer

Views

12190

Archer - An extendable all metal 3D printer

This is an all metal build using OpenBuilds V-Slot linear rails to produce a high quality and cost effective 3D printer. The printer is designed to be scalable for your desired build area and can utilize high quality hotends with 16mm groove mounts such as E3D.

Build Author

Sonny Lowe

Views

5999

Build Author

Sonny Lowe

Views

5999

The MakerSL Customized OB Minimill

This is my interpretation of the OB Minimill, what I've changed so far, and what may continue to change as my requirements change.

My C-Beam 3D Printer

Larger format FDM printer using C-Beam linear stages

KALΔIS OPEN SLA

Modular easy to adjust scale of the entire build Tablet/LCD monitor SLA 3d Printer.

Desktop PCB Maker

With the focus always on larger builds I wanted to focus on a desktop PCB milling machine that fulfills the average users desktop needs at an entry level cost. Design considerations will allow expandable capabilities to include 3D printing and any other functions a small form Cartesian robot can perform. The current iteration has a desktop footprint of approximately 15.5" X 14.5".

3D PrintBot 500x500x500

Large scale True 500x500x500 build volume 3D printer.

Build Author

chenderson

Views

11250

Build Author

chenderson

Views

11250

CRH C-BEAM Router, steel capable

C-beam based CNC router using mostly openbuilds parts.

RSW's 3D Printer Build

I recently completed my C-Beam Plate Maker build ( http://www.openbuilds.com/builds/rsws-c-beam-build.4286/ ) and quickly got the build bug. I was looking for something to make with the new C-Beam and decided its time to venture into the 3D printer world. I can honestly say I have never been in the same room with a 3D printer, so this is going to be a learning experience. I spent some time browsing the 3D printer builds and finally decided to copy the Talos3D by AlexLee.

Build Author

pek

Views

5130

Build Author

pek

Views

5130

V-Slot Hand Cutting Jig

To help cutting v-slots with hand saw

Build Author

Joerharris

Views

5749

Build Author

Joerharris

Views

5749

Joe Harris's all metal CNC Router build

I'm building a CNC router in my garage (almost finished!) and I'm keeping a video build log of the process in the hope it may be useful to others wanting to do the same. I don't have much in the way of fancy tools so expect a bit of innovation on the way!

Build Author

Glenn Weston

Views

9366

Build Author

Glenn Weston

Views

9366

"AcroCadabra" My Acro Laser built with my C-Beam XL

Well I built a C-Beam XL around a year ago, I am still learning things as I make stuff with it, it has been quite a wonderful learning experience. Now I have gained enough confidence and knowhow to Mill the required Plates to build an Acro Laser System using the Acro Laser Sketchup Model. I have pulled the Model apart in Sketchup, isolated the Plates and generated the G-Code to cut/Mill the plates. I have used Sketchucam to generate the G-Code. I Use Mach3 on my C-Beam XL to Mill.

Build Author

Tommy Williamson

Views

5524

Build Author

Tommy Williamson

Views

5524

Motion control camera slider based on the V-Slot® NEMA 17 Linear Actuator Bundle (Belt Driven)

I built a motion control camera slider with the V-Slot® NEMA 17 Linear Actuator Bundle (Belt Driven)

Build Author

Joe Young

Views

4477

Build Author

Joe Young

Views

4477

Goliath - CNC + 3D printer Hybrid

Mostly for Mill work, and FDM 3D printing (mostly Nylonx). I'm currently in the process of adding some hardware for a project requiring lathe work. I've included a solidworks 2014 pack and go for those of you interested in the build. if you need another file type, just let me know and i can try to accommodate. This is a scratch build (electronics and hardware)... see photos. Everything is pretty close to industrial quality... Electronics too. I got sick of other COTS designs breaking down

Build Author

CoreCube3D

Views

18788

Build Author

CoreCube3D

Views

18788

CoreCube3D - A CoreXY 3D Printer

Building a CoreXY based 3D printer using primarily parts from China on eBay. Large 500mm frame.

Gary's Mod Plates for OX Heavy Duty X and Z

Gary's take on the OX HD X and Z plates, making it stiffer, adding mini wheels to the C-beam and Quick removable Z axis.

Build Author

Sergio Di Ventura

Views

7704

Build Author

Sergio Di Ventura

Views

7704

Prusa Dragon LR

Below are the details of my build and a good story for those who read till the end. Sorry for the grammar

Build Author

2SIsurf

Views

4631

Build Author

2SIsurf

Views

4631

Hotwire cnc Surfboards

Xl 2 axis foam cutter Eps Surfboard blanks Simple open concept but high production machine. Shape 3d case with open builds controller

3D printer for printing Clay/Paste

I designed this 3D printer from scratch for my mechanical engineering capstone project. It's made for printing clay but should be able to print any paste material. The clay extruder system could be easily modified to work with almost any 3D printer. The printer is approximately the same size as an Ender 3.

Build Author

Mark Carew

Views

88203

Build Author

Mark Carew

Views

88203

V-Slot™ Mini V Linear Actuator

Learn to build the V-SLOT Mini V Modular linear Actuator System and create all kinds of cool machines!

plasma cnc

Homemade plasma cnc

Routy GT2 300 BSX CNC Router

This is the first project that I would like to share with you. I know the build looks familiar and it is; it’s based on kram242´s Routy. Work area is 300*500*55 mm and is NEMA17/GT2 belt driven.

Build Author

Rakmup

Views

39530

Build Author

Rakmup

Views

39530

CNC Router Lathe

Steel square tube frame with dual feed gantry and indexing lathe section. Will have 36" x 30" x 6" travel. Has a Harmonic Drive on the 4th Axis.

Build Author

Keith Davis

Views

16416

Build Author

Keith Davis

Views

16416

OneZ

OneZ gets it's name from it's most unique feature - only motor for the Z axis while maintaining the stability of two bearing guides for the Z axis. Reduction to one Z motor eliminates need for auto bed leveling.

Build Author

Yoshiya Arii

Views

39011

Build Author

Yoshiya Arii

Views

39011

V-Slot Laser cutter and engraver

The Smart Laser Mini is an open source such as use Raspberry pi. Easy to assemble type of desktop laser cutter and engraver. Also we used V-slot

Build Author

Keith Davis

Views

17992

Build Author

Keith Davis

Views

17992

PrintAir CoreXY

A CoreXY/Bowden design with a belt driven Z axis. This is a box design without the front end of the box, making the print area and maintenance, like changing a nozzle, easily accessible.

SCoreXY

Currently I have Velleman/3Drag K8200 modified and CNC machine self built and wanted to use both to make new 3D printer. After looking at different designs I liked Voron a lot and have decided to go that way. Currently I have ordered majority of parts and build shall start soon. I don't plan to rush it as I am usually 2 months home and 2 off. Today done some electronics. Looks ok. https://youtu.be/ls_tl54ruE0

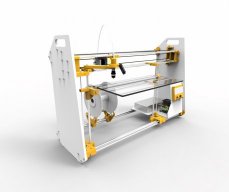

Hlidskjalf, CoreXYU (dual X-carriage)

Dual X-Carriage CoreXY. Not impossible, but probably the only one. Use the link to Thingiverse "Hlidskjalf" for parts and downloads.

MakerSL MSL-21 OB Minimill Enclosure

Simple enclosure for the OB Minimill

Build Author

GDanger117

Views

10314

Build Author

GDanger117

Views

10314

Gantry CNC - Decisions made only to change over and over.

This is my first CNC build. As per the norm, I went in with months of research, planning, and resource gathering tied neatly together with a solid plan. As the path went on, the plan continued to change to accommodate issues I hadn't counted on. But, at the end of the road, the project reached completion, and I learned a ton along the way!

Build Author

Keith Davis

Views

4474

Build Author

Keith Davis

Views

4474

Torq Xtrdr

Light enough for high speed #3dprinting Strong enough for high speed #3dprinting

Build Author

Rob Mahan

Views

11605

Build Author

Rob Mahan

Views

11605

Rob's C-Beam Machine XLarge

This is my first CNC router build, so I started with the OpenBuilds C-Beam Machine XLarge mechanical bundle, including four high torque stepper motors. I took my time with the mechanical build, sought and found some great help for my control system, and designed and built a custom cabinet to house everything.

EOX

Open builds style wood CNC router. Usable work aria 1000mm x 1250mm x 150MM (X x Y x Z). 80x40 C bleam for the Y axis , two 60x20 beams for X axis and a 60x20 fo Z. Interlocking GT3 belts for X and Y. Looking to change over to a rack and pinion system in the future. 8x8Tr Lead screw for the Z. Leadshine HBS507 close loop drivers and 3-phase servo motor 573HBM20-EC-1000 motors driving the Y and X axis. Would recommend them to anyone looking for servo like performance at a affordable price.

Draw bot core xy

In the design stage. Help guide.

Build Author

BNMaker

Views

9932

Build Author

BNMaker

Views

9932

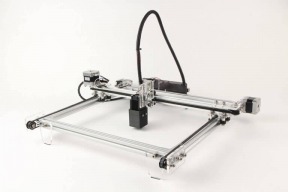

+Laser

A minimalist 2-axis A2 sized laser diode cutter/engraver. Designed to give the most function using the very least number of parts at the lowest price.

Build Author

Mark Carew

Views

29178

Build Author

Mark Carew

Views

29178

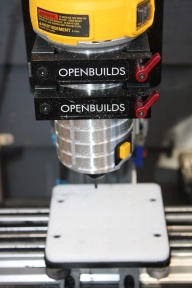

OpenBuilds Sphinx 1050 (20" x 40")

The OpenBuilds Sphinx 1050 - 500x1000 Lead Screw Machine

HandCrafted WorkBee - HCWB

This will be a slow build as I collect parts and materials as funds permit for 1000mm x 1000mm Workbee. I call it the "Hand Crafted WorkBee" because I will be hand making the plates and as much of the build as possible using a drill press and hand tools.

Build Author

deltajegga

Views

8401

Build Author

deltajegga

Views

8401

THE delta

probably as big as you'd want it...

Build Author

obmilllivebuild

Views

10452

Build Author

obmilllivebuild

Views

10452

Live OpenBuilds MiniMill -> MiniPrint/Laser Conversion Demo @ MRRF2019

Transformation of an OpenBuilds Mini Mill into a convertible 3D printer / CNC mill with interchangeable tooling. Maybe a bonus conversion TBD.

MiniMill build

A table top OpenBuilds MiniMill build. 48V 52mm spindle with ER11 collets.

Reworked Routkit SD

I could not "tram" the spindle to the table. I found that the V Rails could not accurately be adjusted so the Gantry was equal distance from the spoilboard in multiple places.

A Rolling Plotter

To build a simple plotter that rolls along the length of large paper, foam core or other flat objects.

Build Author

ajdubs

Views

3518

Build Author

ajdubs

Views

3518

A custom arcade

This is an arcade "cabinet" of sorts built almost entirely from OpenBuilds extrusions. Save for a few 3d printed parts, the electrical components, the acrylic panels, and the monitor mount, every component was purchased from the OpenBuilds part store.

Build Author

OpenBuilds

Views

23100

Build Author

OpenBuilds

Views

23100

INTERFACE CNC Touch Control System

Super cool standalone Human-Machine Interface for controlling your CNC machines!

Build Author

CNCGear

Views

8621

Build Author

CNCGear

Views

8621

The BlackBee CNC

Ball screw drive, linear rail CNC Kit

Magnetic CNC Dust Shoe with LED lights and Camera*

Making my own magnetic dust shoe with led lights and a camera. Showing my progress from beginning to now.

DIY Vacuum Hold Down table

A simple vacuum hold down/clamp set up using a 6hp canister vacuum.

Desktop CNC

A desktop Cartesian CNC router

Build Author

Jason Moore

Views

10462

Build Author

Jason Moore

Views

10462

Lead1500 Plasma Table w/THC

lead machine plasma table with Black Box, and Torch Height Control

Camera slider for stacking focus

This is just a small project to get use to the OpenBuild products.

Dual Extruder 3D Printer and Laser Cutter combo

Dual extruder 3D printer and laser cutter.

Flexible Axis Revolving Tool-holder

Drag knife and pen holder which mounts in spindle collet.

CubeFoot CNC

This small desktop machine is built inside a 300mm cube of 20mm extrusion. Work area is 14cm by 14cm. I used 400 step nema17 motors all around.

Build Author

Mark Carew

Views

57904

Build Author

Mark Carew

Views

57904

V-Slot NEMA 23 Linear Actuator (Lead Screw)

Learn to build a super strong nema 23 lead driven linear actuator

Build Author

Mark Carew

Views

117826

Build Author

Mark Carew

Views

117826

C-Beam™ Linear Actuator

Here are a few helpful C-Beam actuator ideas that will help you get a start on your builds

Rex

This build is inspired by the Lulzbot Taz printers and makes use of the new OpenBuilds C-Beam

My Second CNC

In short...this was a fun project.

Build Author

UltiBots

Views

9539

Build Author

UltiBots

Views

9539

Machined Aluminum MagBall Carriages

Machined Aluminum MagBall Carriages

Build Author

crystaldragon141

Views

5595

Build Author

crystaldragon141

Views

5595

Rostock TETRA V0

This is an experiment to build a Linear Delta Printer using four towers instead of three. Primary reasons: 1. Build area is roughly cubic vs roughly cylindrical 2. Greater speed and precision from additional control provided by fourth tower. 3. Symmetric kinematics from even number of towers.

My first OX build

This is the story of my experience building a 1000 x 750mm OOZNest OX CNC router

1000mm X 1000mm with tinyg

1000mm X 1000mm overhead cnc machine

My first printer

My first printer! I went for a simple cartesian design, based on evilc66 one. It uses 1000 mm C-beam linear actuators. The build volume is 700x700x700 mm^3.

Project There is No Kill Like Overkill

Very stout 2'x4' machine with a deep Z axis

Build Author

Hisha

Views

7898

Build Author

Hisha

Views

7898

Sphinx XL/R7

A 1000mm x 1000mm Sphinx/R7 build.

Build Author

megashub

Views

21593

Build Author

megashub

Views

21593

K40 C02 Laser Rail System

An Openbuilds replacement rail system for the common eBay "K40" C02 Laser Cutter

Automatic Sprayer

Automatic spray machine.

Build Author

Carl Siren

Views

6359

Build Author

Carl Siren

Views

6359

CNC-machine 650by700

A home-made CNC-machine with a 1.5 kW air cooled spindle motor suitable for milling materials such as wood, plastic and soft metals. The work table is 650 mm wide by 700 mm deep and the maximum movement is set to 560 mm for the x-axis, 480 mm for the y-axis and 105 mm for the z-axis.

Build Author

Calotype

Views

2594

Build Author

Calotype

Views

2594

My DIY panoramic rolling (&banding) Machine.

DO WHAT YOU IMAGINE !

Build Author

Lasersc

Views

9448

Build Author

Lasersc

Views

9448

D&R Tiger Paw build combo

The Tiger Paw will be a 1000mm X 500mm Cartesian style CNC with the Minimill attached to the end. It is named the D&R Tiger Paw because my son, Daniel, and myself, Richard, will put this Tiger strong and fast machine together. Our goal is to have a Tiger strong build with a Paw print that wouldn’t take up a huge amount of space in our garage.

Build Author

Mark Carew

Views

47628

Build Author

Mark Carew

Views

47628

OpenBuilds Sphinx 55 (20" x 20")

The OpenBuilds Sphinx 55 - 500x500 Lead Screw Machine

Build Author

reef

Views

10419

Build Author

reef

Views

10419

CNC Cyclone PCB Factory, my way, step by step.

I'd like to renew my cnc for PCB so I decide to create new one from an existing project named Cyclone PCB Factory.

CNC Lathe Upgrade

So, not much here, as I'm still building, but I'm putting in the work.

Build Author

Luke Cunningham

Views

4997

Build Author

Luke Cunningham

Views

4997

Tronxy X1 extension

Video on youtube: https://www.youtube.com/watch?v=vCTbLZ2_m-w&t=36s

Build Author

Rob Taylor

Views

8965

Build Author

Rob Taylor

Views

8965

Grizzly G0758 Benchtop Mill Conversion

A proper CNC mill conversion. But quite small, with my trademark idiosyncracies.

The Spice Must Flow: a coreXY Sand Table

A 1.9 x 1 m table that uses a magnet to move a steel ball and draw geometric patterns in sand. The magnet is moved using a corexy mechanism driven by 3D printer controller board reading the patterns in the form of gcode files.

Build Author

pedrofernandez

Views

8669

Build Author

pedrofernandez

Views

8669

K40 Cube Laser Cutter

The k40 cube is a laser cutter build using mostly stock parts of the chinese k40 laser

Lead CNC build, Mansfield, Texas - BUILD COMPLETED WITH REVIEW OF THE KIT

The machine is a stock Lead CNC, with the Black Box controller and StepperOnline 269oz NEMA 23 motors. I'll be using the DeWalt 611 from Openbuilds, as well.

My build

I am satisfied with my build and next one will be even better.

Build Author

Vunnie

Views

5803

Build Author

Vunnie

Views

5803

Workbee CNC on steroids

My First major improvement was changing the controller to a Acorn board. I loved the way a dedicated userinterface was speeding up my workflow. Next project my Y Axis. On Aliexpress I ordered a couple of 16mm ballscrews and some lineair rail. Before I took my gantry off I quickly made some aluminium profiles to fit my carriages. Withouth any doubt these improvements where worth it

Build Author

Keith Davis

Views

8457

Build Author

Keith Davis

Views

8457

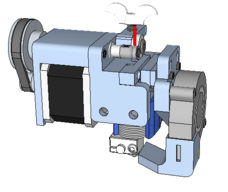

Upgrading Your 3D Printer With Synchronous Leveling

Upgrading printers for Synchronous Leveling

C-Beam Dust Shoe

A short description of the dust shoe I made for my machine.