MMXL - A MiniMill Conversion

Discussion in 'CNC Mills/Routers' started by Scotty Orr, Oct 29, 2017.

MMXL - A MiniMill Conversion

Discussion in 'CNC Mills/Routers' started by Scotty Orr, Oct 29, 2017.

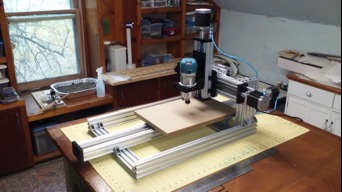

Using most of the parts of the MiniMill, and adding a few other parts (cost < $200), transforms the MiniMill into a very capable machine. Final build area as shown is 10.25" x 16". With a custom Y-plate, I will take it to 10.25" x 20-24".