LEAD Lathe

Discussion in 'CNC Lathes' started by Giarc, Jun 14, 2020.

LEAD Lathe

Discussion in 'CNC Lathes' started by Giarc, Jun 14, 2020.

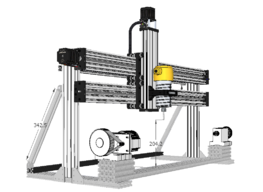

I have been toying with the idea of making a 3 axis rotary CNC machine for awhile. I wanted to make it with off the shelf OpenBuilds parts so any one can replicate it and I felt the LEAD High Z Mod would be a good starting point.

Page 1 of 5

Page 1 of 5