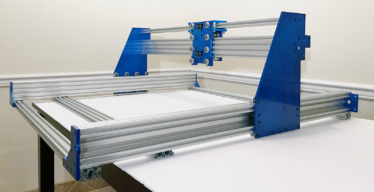

Spartacus Inspire

Discussion in 'CNC Mills/Routers' started by MarkM_NJ, Feb 27, 2018.

Spartacus Inspire

Discussion in 'CNC Mills/Routers' started by MarkM_NJ, Feb 27, 2018.

My very first openbuilds cnc machine. Followed along DaztheGas's Spartacus build.