First and foremost thank you to DazTheGas, for the inspiration, answering a few questions I had and for your detailed videos. Also thank you to everyone on the forums for answering my questions.

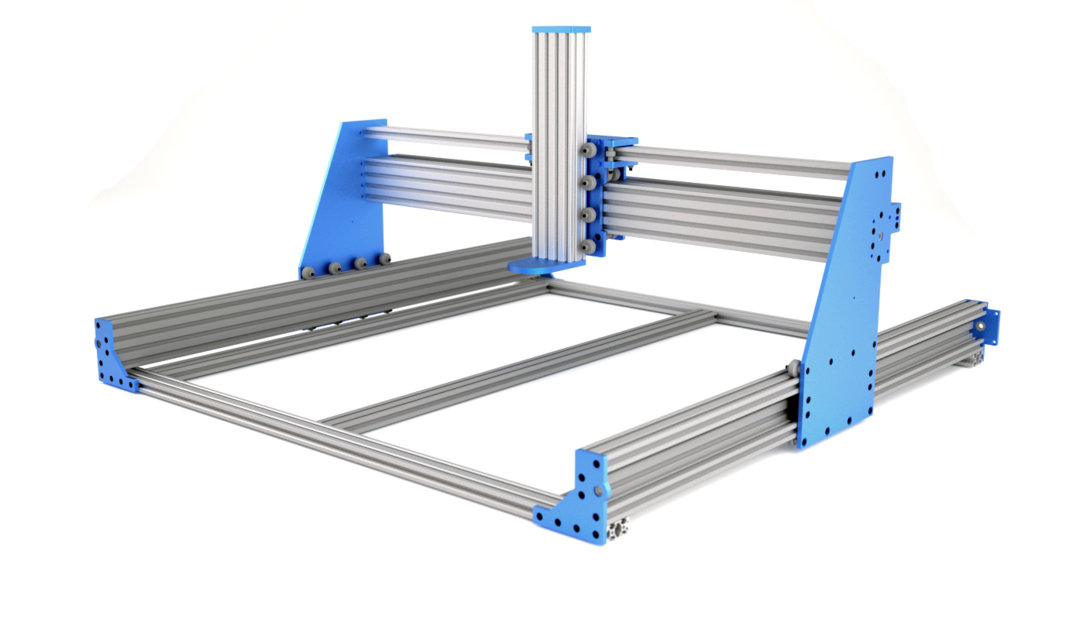

I have wanted a lead screw driven machine for a little while now. I will detail my build as much as I can. If you have any questions, feel free to ask.

12/19/2018 – Update

Modified gantry plates so that the x axis 20x40 vrail can be adjusted to accommodate any tolerance issues for the v-wheels in the x axis assembly.

Also updated parts list with electronic components I used. Instructions coming shortly.

_________________

The plates where designed in Rhino3d. I uploaded a dxf file and also step files.

You have two options for the plates that a motor connects to (gantry, motor end mounts).

First option is to have the screw go thru the plate, spacer, motor then nut.

Or you can have the screw go thru the motor then screw into the plate. You will need to tap 5mm threads into the plates, the holes are 4.2mm in the files for this. The files you will want to do will have tap_holes in the file name.

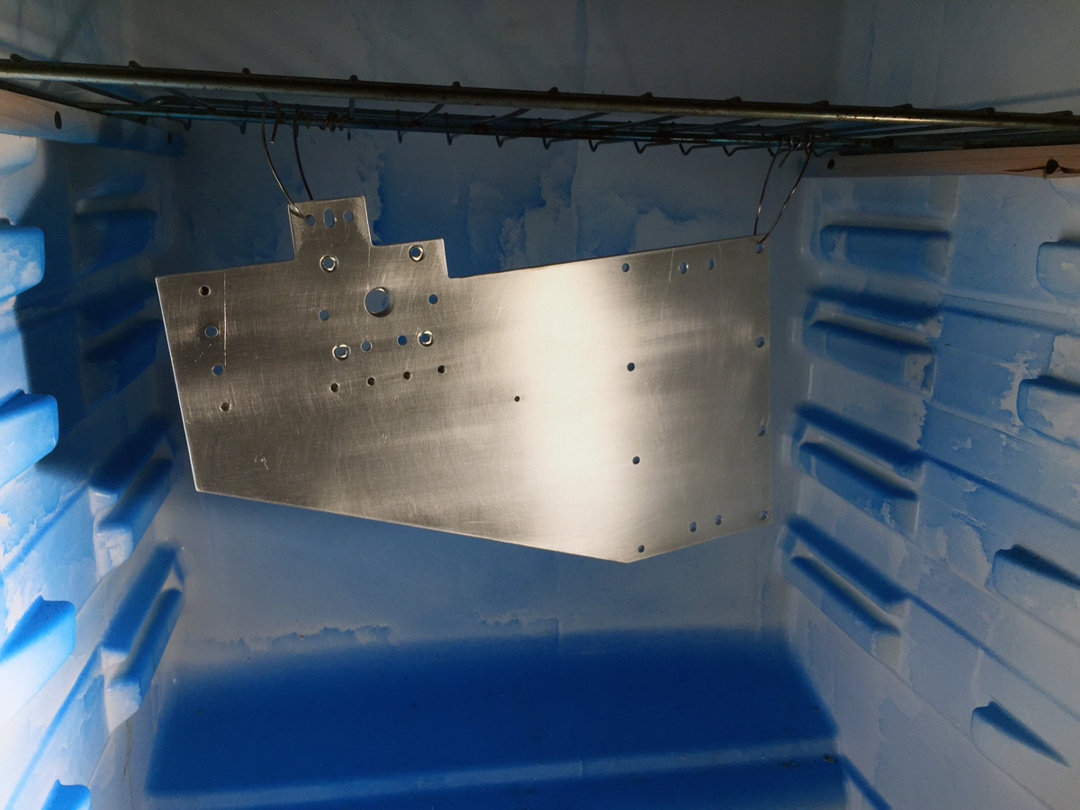

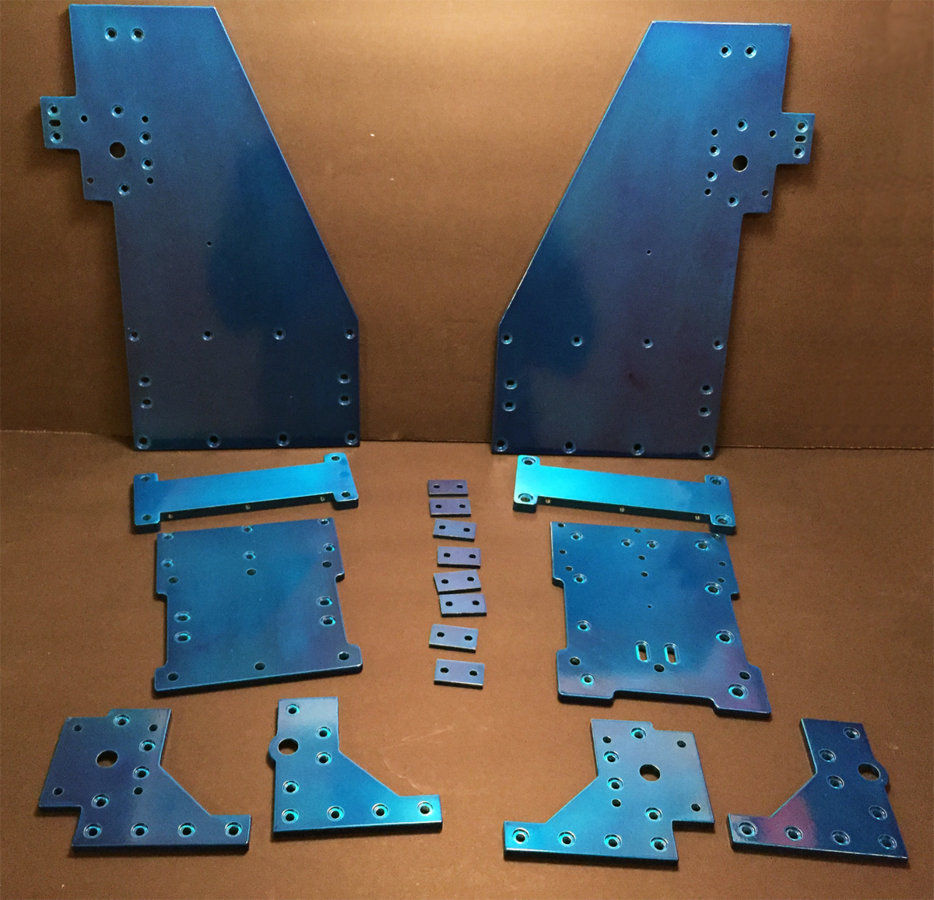

Adding Color – Powder Coating

I decided to powder coat my plates rather then anodizing, as this was the easier option. I seen this blue that a fellow member used in the facebook group and really loved the color. It's called anodized blue.

I have a craftsman electric powder coat gun ( no air compressor needed). Really great for the diy-er, without the hassle of setting up your air compressor, if you don't have one easily available. Craftsman has discontinued selling them. But non-branded ones are readily available on eBay if you're interested in one. They do have a few flaws that are easily workable.

First thing was prepping the aluminum plates. I used a scuffing pad on a regular cordless drill and also some 200 then 400 grit sand paper to remove scratches. Then I used a automotive scuffing pad for the final. Once that was done, I cleaned them off with simple green extreme as it is safe for aluminum. Then I rinsed off with water, then let dry.

Once I was ready to apply the powder I preheated an old oven to 400F degrees. And hung my part onto an oven rack with metal wire into a makeshift spray booth. You connect the grounding wire from your gun to your part ( I connected to the metal wire, which was a good connection.) I wore plastic gloves to be sure I didn't get skin oil onto the parts.

I went ahead and sprayed my part with powder, then carefully took it over to the oven, making sure I didn't bump into anything.. You keep an eye on it and wait for it to gloss over ( turns to liquid state). Once the gloss over happens, you wait ten minutes then take it out of the oven to cool.

You always want to wear respiratory protection. Also never use an oven for food after using it for powder coating. Also temperature and oven times will depend on the powder you use. So always check the manufacture recommendations.

Assembly

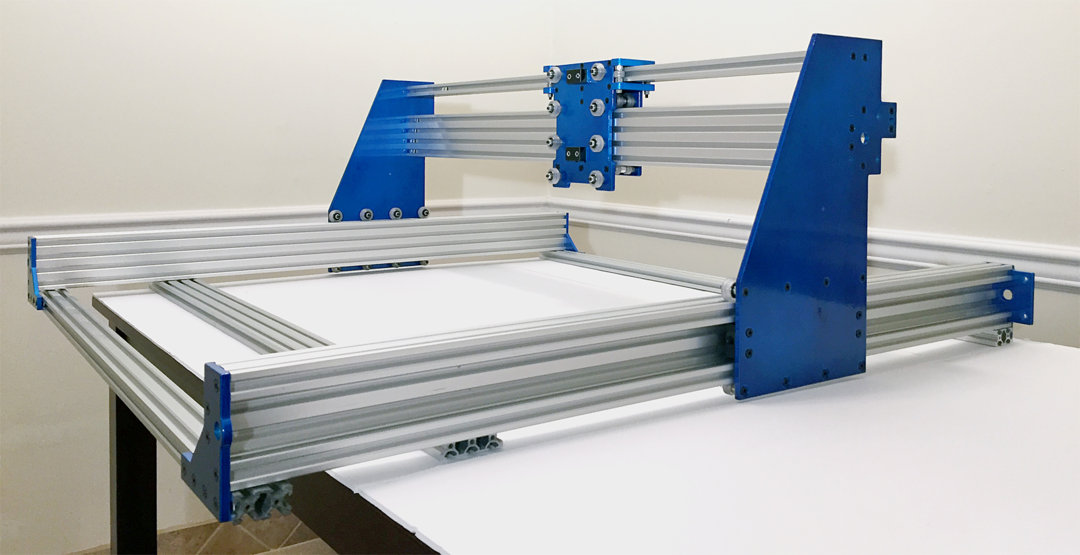

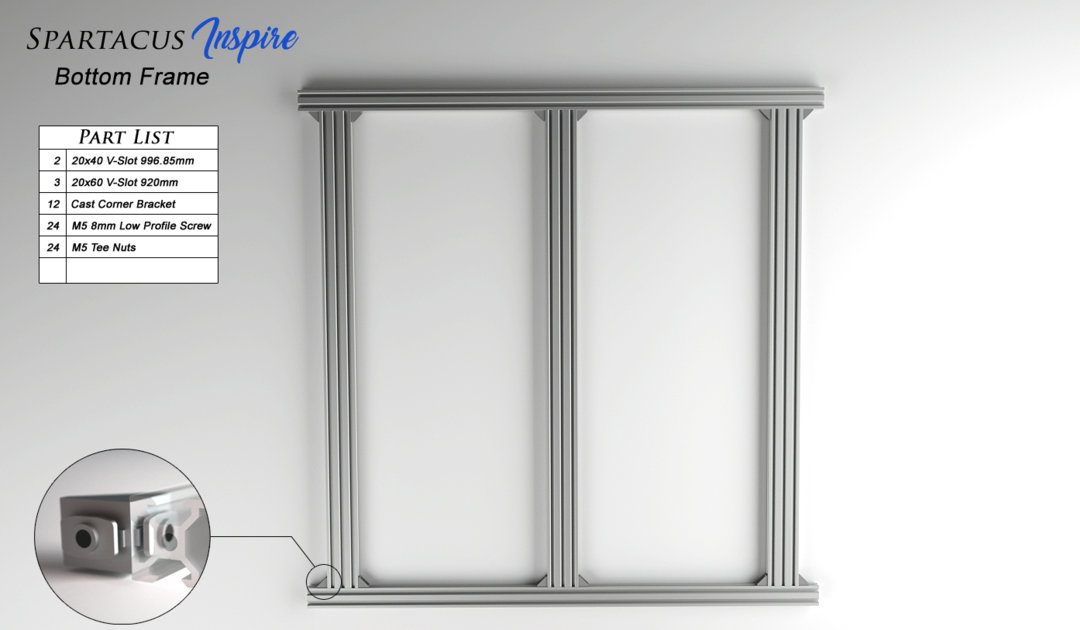

The bottom frame layout. The 20x60 v-slot is optional, as the 20x40 v-slot will be attached to the cbeam by the end mount plates.

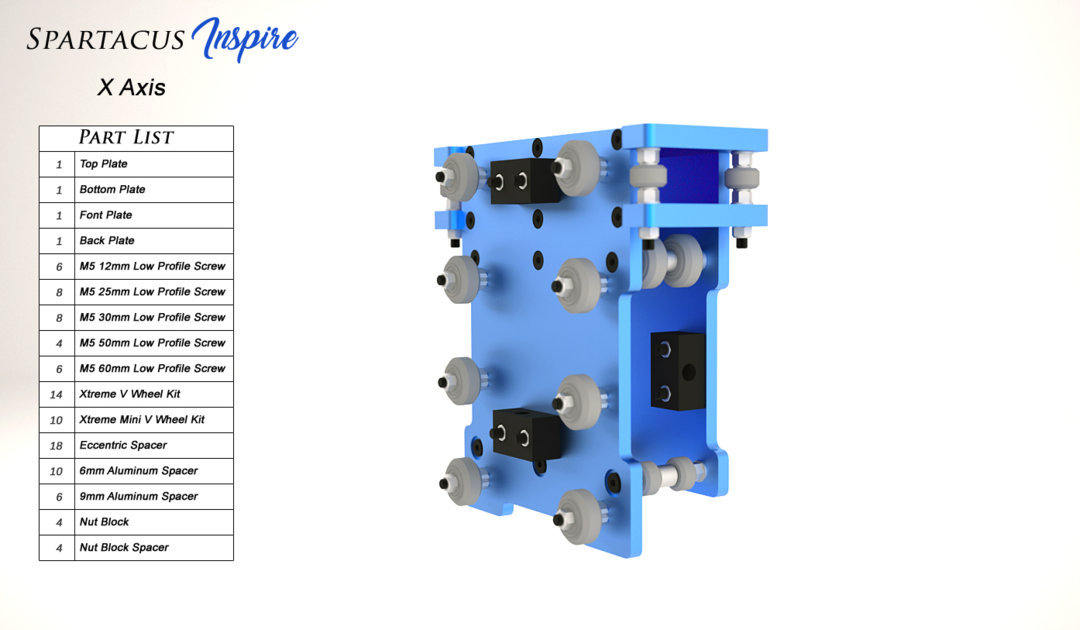

I started by putting together the x-axis plates.

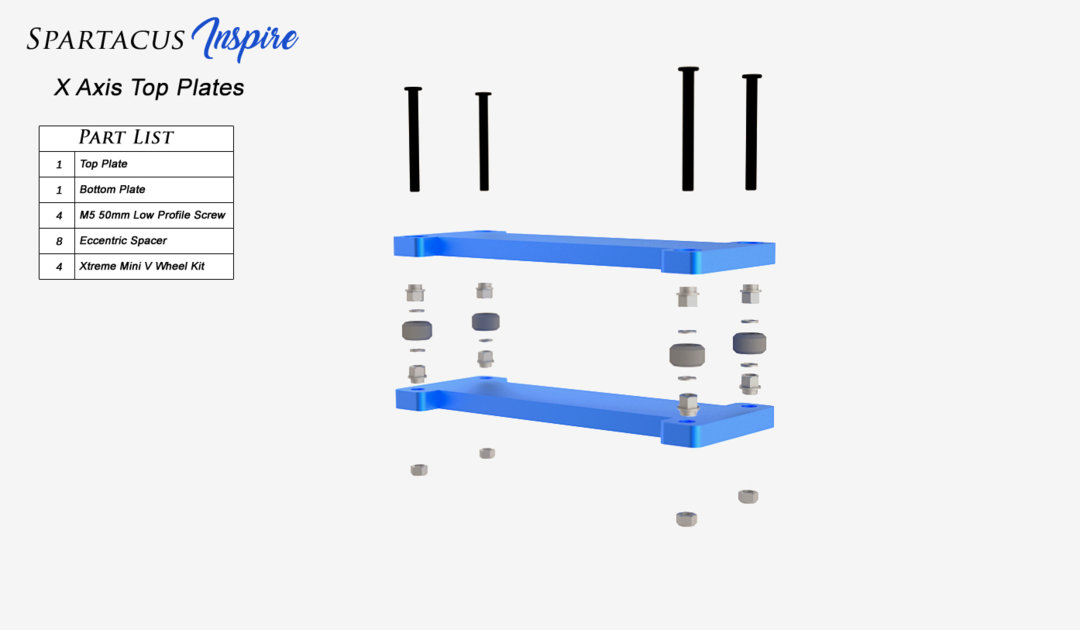

I first put together the top and bottom x axis plates. I set the eccentric spacers so that its the greatest distance apart. Once I have the top component assembled, I went ahead and set the eccentric spacers with a piece of 20x40 v-slot. I place this part to the side for now.

Then install the four M5 60mm screws. I don't install the back wheels just yet. (The screw heads are too large to clear the front V Wheels, but you do have enough clearance with the front wheels installed to tighten.)

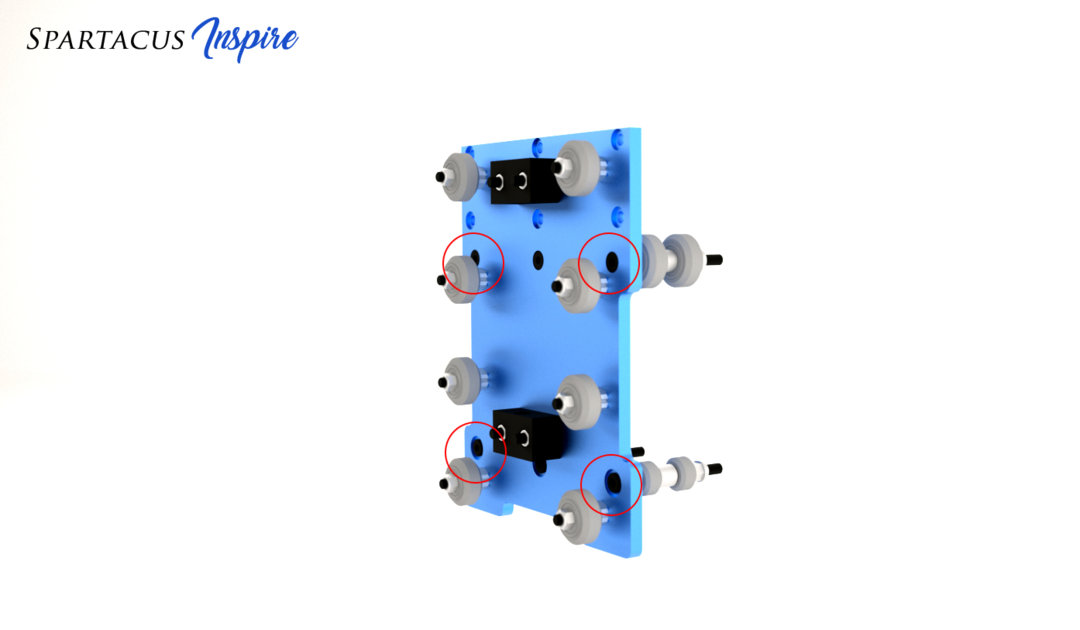

Go ahead and install the eight front V Wheels, the eccentric spacers are installed on the right side and 6mm spacers installed on the left. Then install the nut block with spacers. Then install the top component to the front plate with three M5 12mm screws. Then set the eccentric spacers with a piece of cbeam.

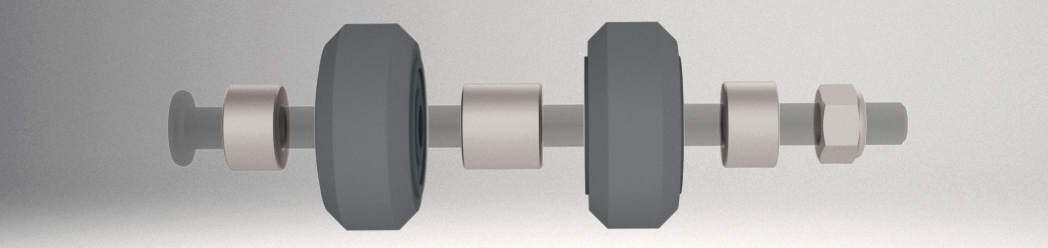

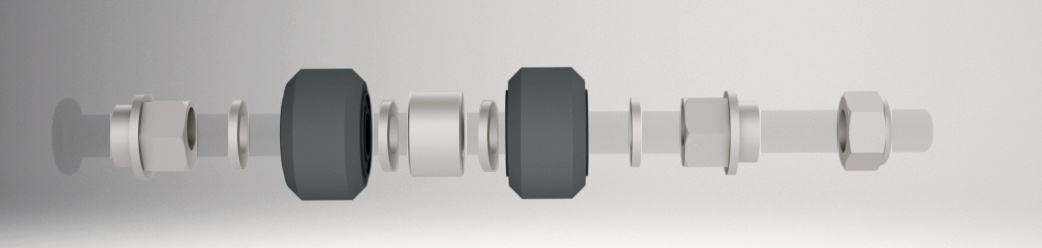

Install the other two M5 60mm screws. The top screws get a 6mm spacer, v wheel, 9mm spacer, v wheel, 6mm spacer.

The lower screws get an 6mm eccentric spacer, precision shim, mini v wheel, precision shim, 9mm spacer, precision shim, mini v wheel, precision shim, 6mm eccentric spacer.

Install the back plate and add nuts to your screws. Then set your eccentric spacers with a piece of cbeam.

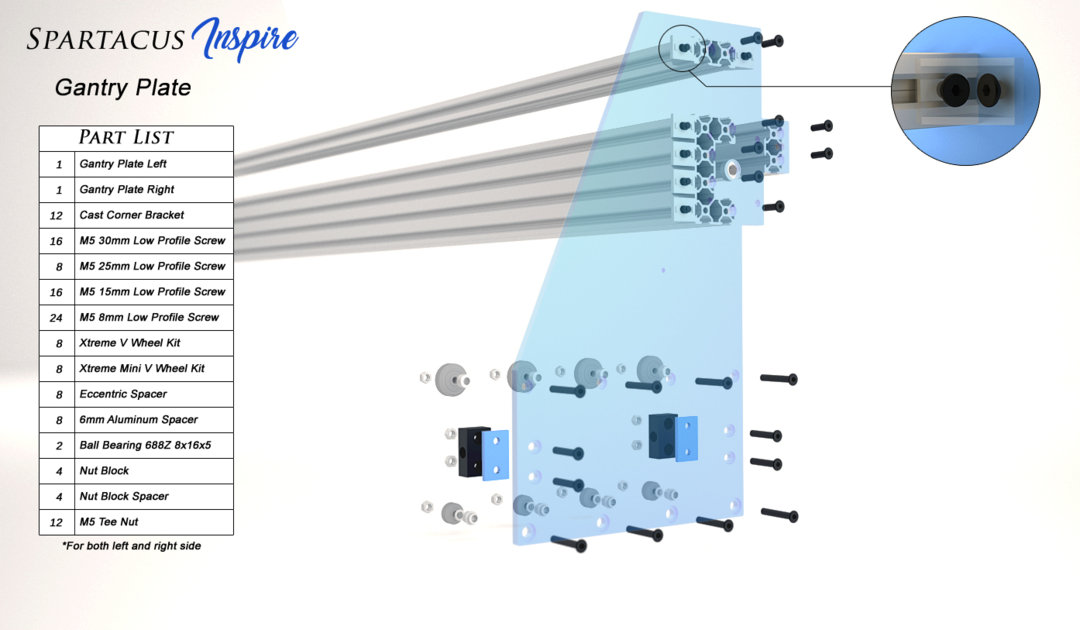

Install the V Wheels onto the gantry plates. The top wheels are the standard size V Wheels. The setup uses a 6mm spacer, V Wheel, nut. The bottom wheels are the mini V Wheels, the set uses a 6mm eccentric spacer, 1mm precision shim, mini V Wheel, nut. Then install the nut block spacers then the nut blocks.

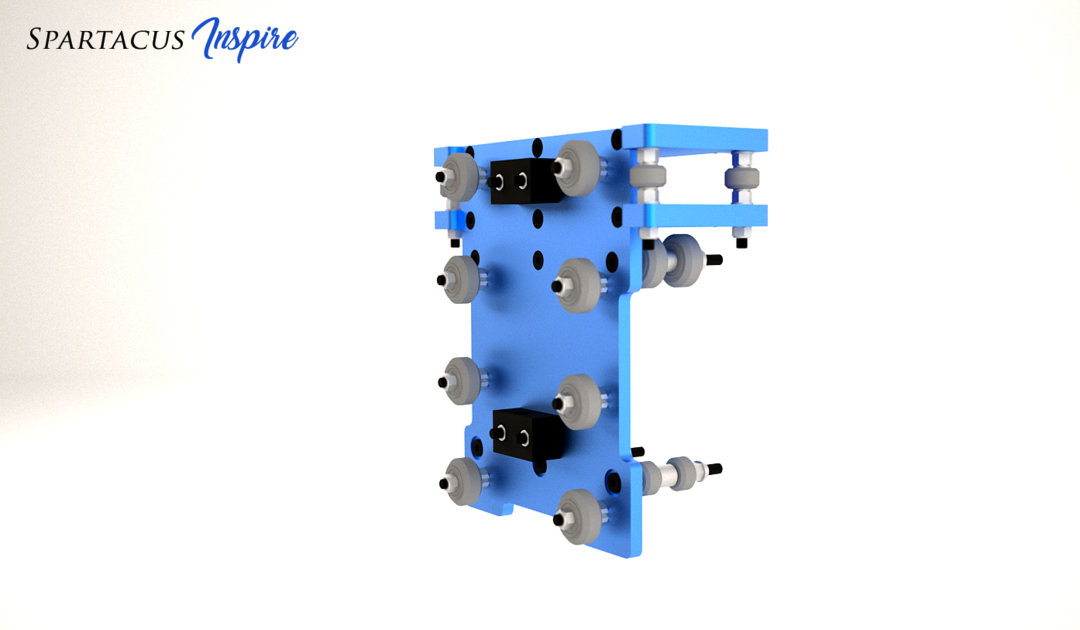

Attach the cbeam and the two 20x40 vrail to one of the gantry plates. (M5 holes need to be tapped in the vrail.) Then slide on your x axis assembly. Attach the other gantry plate.

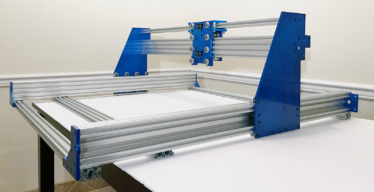

Slide the cbeam into the gantry plates. Then place 20x40 vrail under the y cbeam on each side.

Next install your end-mount plates.

Z Axis

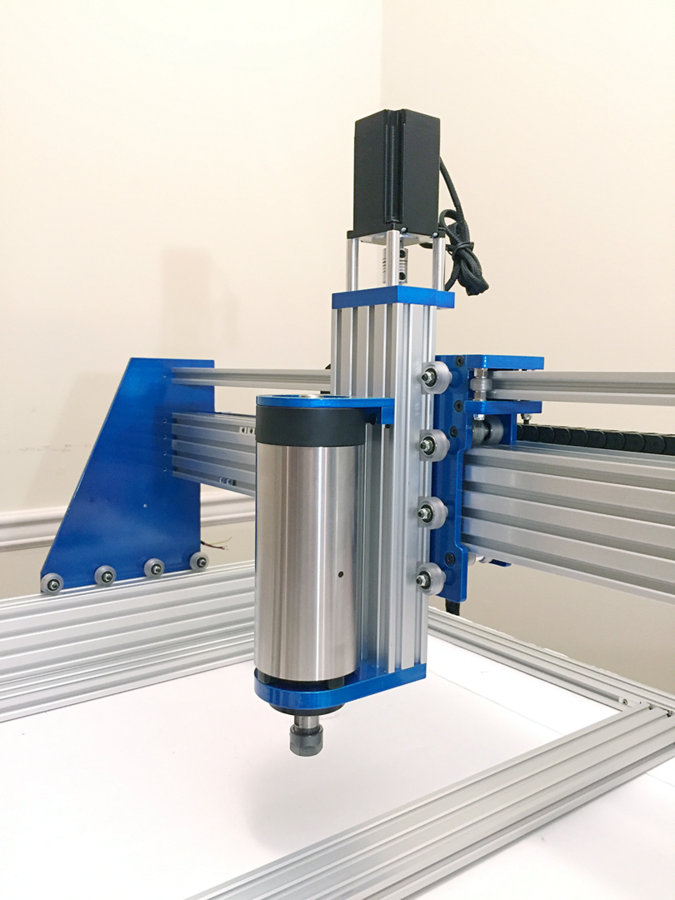

I decided to go with a 1.5kw air cooled 80mm spindle. I have updated the files with this setup. I'll be adding assembly instructions shortly.

(disregard attached images below, images were updated above)

Spartacus Inspire

Build in 'Cartesian Style CNC' published by MarkM_NJ, May 22, 2019.

My very first openbuilds cnc machine. Followed along DaztheGas's Spartacus build.

-

-

-

- Build Progress:

-

- Build in Progress...

Attached Files:

Johnny Jensen, Ahmedmusa, Jacob Freeman and 52 others like this. -

-

Build Author MarkM_NJ, Find all builds by MarkM_NJ

-

- Loading...

-

Build Details

- Build License:

-

- CC - Creative Commons Public Domain (CCO 1+)

Inspired by

DazTheGas -

Parts list

-

Attached Files:

-