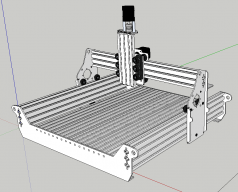

Pocket Ox (Sheetmetal)

Discussion in 'CNC Mills/Routers' started by openhardwarecoza, Jul 12, 2015.

Pocket Ox (Sheetmetal)

Discussion in 'CNC Mills/Routers' started by openhardwarecoza, Jul 12, 2015.

Small CNC - made with some custom lasercut+bent sheetmetal parts + Openbuilds V Slot