Mushu - Large Scale CoreXY

Discussion in '3D printers' started by Shortyski13, May 6, 2019.

Mushu - Large Scale CoreXY

Discussion in '3D printers' started by Shortyski13, May 6, 2019.

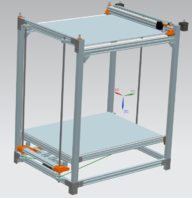

20x26x28 inch Build Volume CoreXY. Unlike many builds, I've decoupled the XY movements from the Z-Axis lead screws to help prevent Wobble, will be using linear guide rails, and mains powered bed heater, and a bed that is Allowed to thermally grow. This build is JUST narrow enough to fit through a standard sized doorway.