Live OpenBuilds MiniMill -> MiniPrint Conversion Demo @ MRRF2019

Discussion in '3D printers' started by obmilllivebuild, Feb 21, 2019.

Live OpenBuilds MiniMill -> MiniPrint/Laser Conversion Demo @ MRRF2019

Discussion in '3D printers' started by obmilllivebuild, Feb 21, 2019.

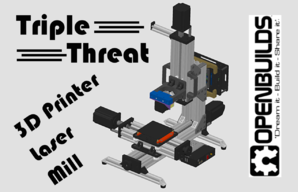

Transformation of an OpenBuilds Mini Mill into a convertible 3D printer / CNC mill with interchangeable tooling. Maybe a bonus conversion TBD.