CoreXY - e3d inspired

Discussion in '3D printers' started by j0achim, May 1, 2018.

CoreXY - e3d inspired

Discussion in '3D printers' started by j0achim, May 1, 2018.

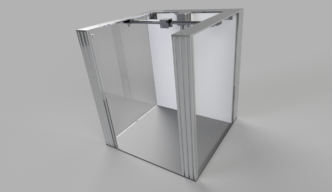

CoreXY printer heavily inspired by e3d's new open source printer with tool changing. I intend to make it so when e3d start selling toolheads these can be added to the machine without any major work having to be done.

Page 1 of 2

Page 1 of 2