C-Beam cnc

Discussion in 'CNC Mills/Routers' started by Kyo, Jun 24, 2016.

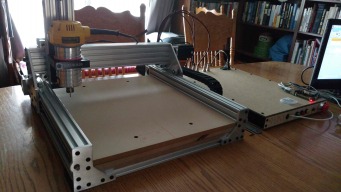

C-beam Sphinx

Discussion in 'CNC Mills/Routers' started by Kyo, Jun 24, 2016.

A strong desktop cnc router that will enable you to make larger aluminium plates without taking up to much room. Simple, strong and opensource ! Build one today..

Page 19 of 20

Page 19 of 20