Add more V-Slot to my Makerfarm 10" Prusa i3v

Discussion in '3D printers' started by David Bunch, Sep 30, 2019.

Add more V-Slot to my Makerfarm 10" Prusa i3v

Discussion in '3D printers' started by David Bunch, Sep 30, 2019.

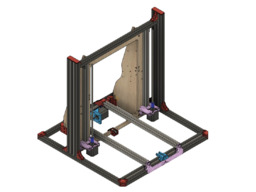

Upgrade my 5 year old Makerfarm printer to use more V-Slot

Page 1 of 3

Page 1 of 3